AND

BEARING

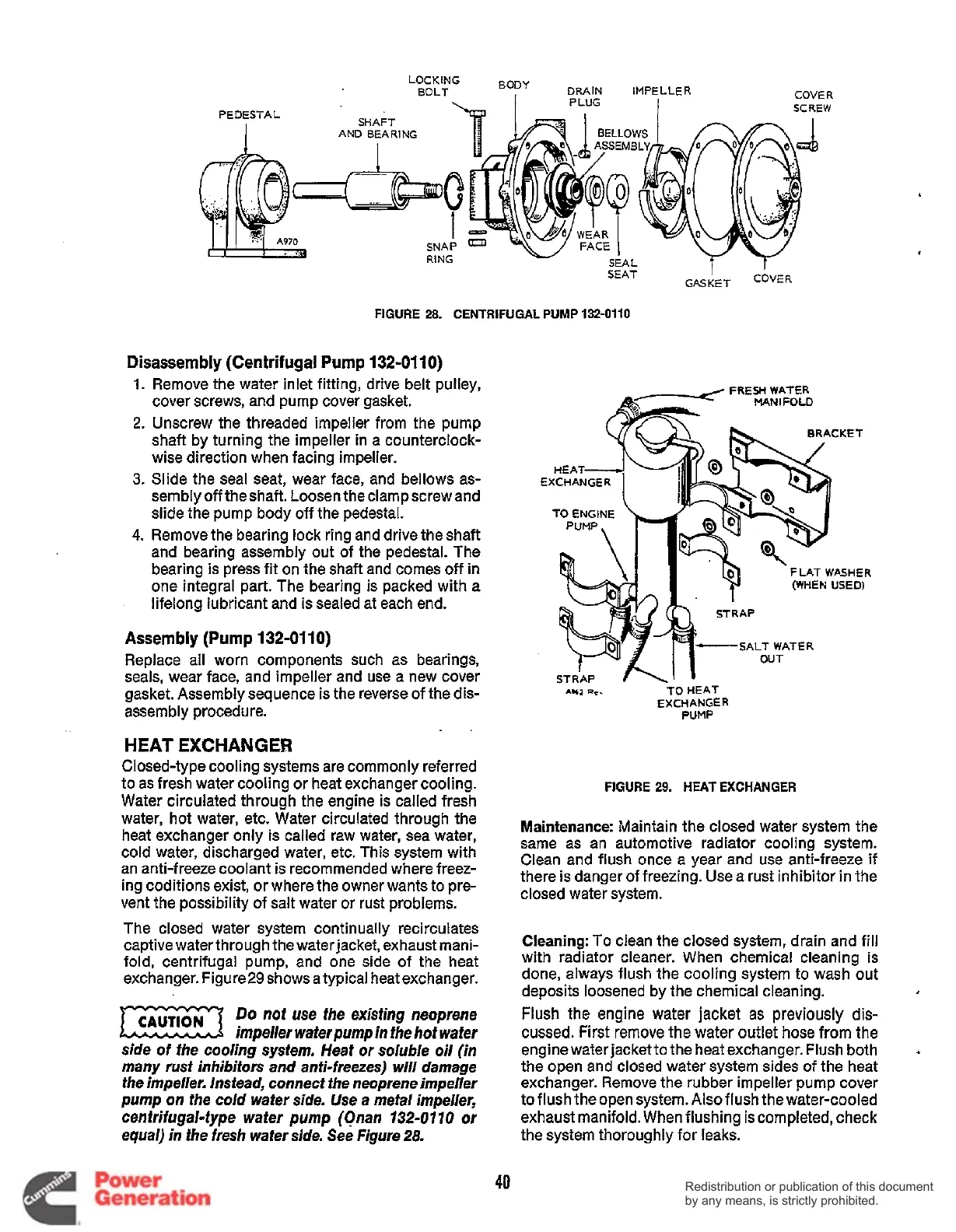

FIGURE 28. CENTRIFUGAL PUMP 132-0110

Disassembly (Centrifugal

Pump 132-01

10)

1.

Remove the water inlet fitting, drive belt pulley,

FRESH WATER

MAN

I

FOLD

cover screws, and pump cover gasket.

2.

Unscrew the threaded impeller from the pump

shaft by turning the impeller in a counterclock-

wise direction when facing impeller.

3.

Slide the seal seat, wear face, and bellows as-

semblyofftheshaft. Loosentheclampscrew and

slide the pump body

off

the pedestal.

4.

Remove the bearing lock ring and drive the shaft

and bearing assembly out of the pedestal. The

lifelong lubricant and is sealed at each end.

E

bearing is press fit on the shaft and comes

off

in

one integral part. The bearing is packed with a

FLAT WASHER

(WHEN

USED)

Assembly

(Pump 132-0110)

SALT WATER

Replace all worn components such as bearings,

seals, wear face, and impeller and use a new cover

gasket. Assembly sequence is the reverse of the dis-

TO

HEAT

EXCHANGER

assembly procedure.

PUMP

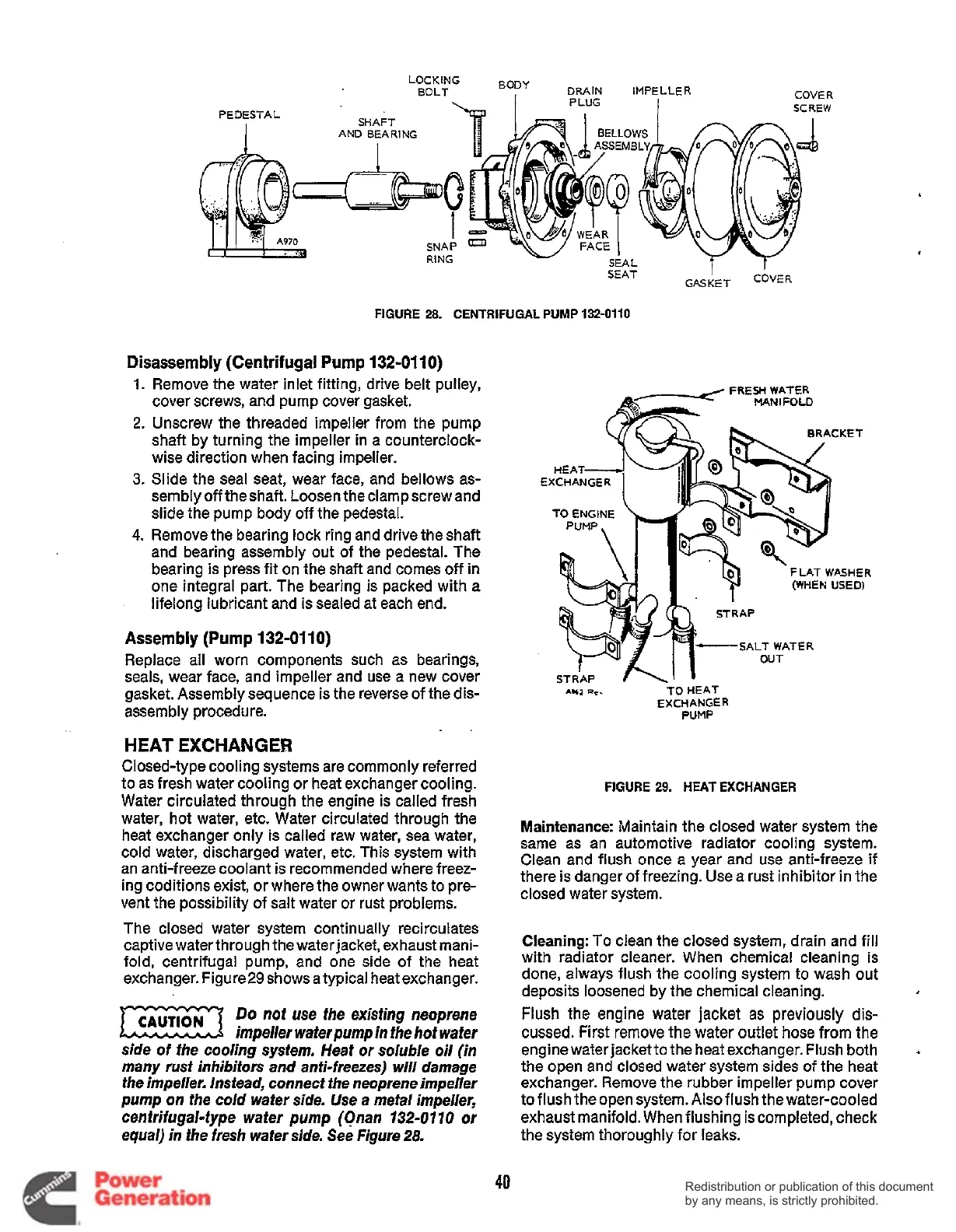

HEAT

EXCHANGER

Closed-type cooling systems are commonly referred

to as fresh water cooling or heat exchanger cooling.

Water circulated throuah the enaine

is

called fresh

FIGURE

29.

HEAT EXCHANGER

water, hot water, etc. fiater circilated through

the

heat exchanger only is called raw water, sea water,

cold water, discharged water, etc. This system with

an anti-freeze coolant is recommended where freez-

ing coditions exist, or where the owner wants to pre-

vent the possibility of salt water or rust problems.

Maintenance: Maintain the closed

water

system the

Same

as

an

automotive

radiator

cooling

system.

Clean and flush

Once

a

year and

use

anti-freeze

if

there

is

danger

of

freezing.

Use

a rust

inhibitor

in

the

closed

water

system.

The closed water system continually recirculates

captive water through the waterjacket, exhaust mani-

fold, centrifugal pump, and one side of the heat

exchanger. Figure29 shows a typical heat exchanger.

Cleaning:

To

clean the closed system, drain and fill

with radiator Cleaner. When chemical Cleaning

iS

done, always flush the cooling system to wash out

deposits loosened by the chemical cleaning.

Do

nof use the exisfing neoprene

impeller waferpump in fhe hof wafer

side of the cooling system. Heat or soluble oil (in

many rust inhibitors and anti-freezes) will damage

the impeller. Instead, connect the neoprene impeller

pump on the cold wafer side. Use a metal impeller,

cenfrifugal-type wafer pump (Onan

732-07

70

or

equal) in ihe fresh wafer side. See Figure

28.

Flush

the engine water jacket

as

previously

dis-

cussed. First remove

the

water outlet hose from the

engine water jacket to the heat exchanger. Flush both

the open and closed water system sides of the heat

exchanger. Remove the rubber impeller pump cover

to flush theopen system.

Also

flush thewater-cooled

exhaust manifold. When flushing

is

completed, check

the system thoroughly for leaks.

.

40

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...