Belt

Drive:

V-belts are preferable to flat.belts.

CorfsOTf

a reliable belting supplier for recommendations

regarding size

of

pulleys, number

of

belts, etc.,

required.

A

typical belt drive installation is

shown

in.

Figure 1.

.

Comply with the following installation requirements:

1.

Shafts of engine

and

load must be parallel with

2. Pulleys of engine and load must be in alignment.

3. Mount engine pulleys as close to engine as

possible.

4.

If installation permits, belts should run horizon-,

tally.

5.

Some method of disconnecting the load for

starting

is

recommended. If a clutch is not used, a

belt-tightener idler arrangement can be used.

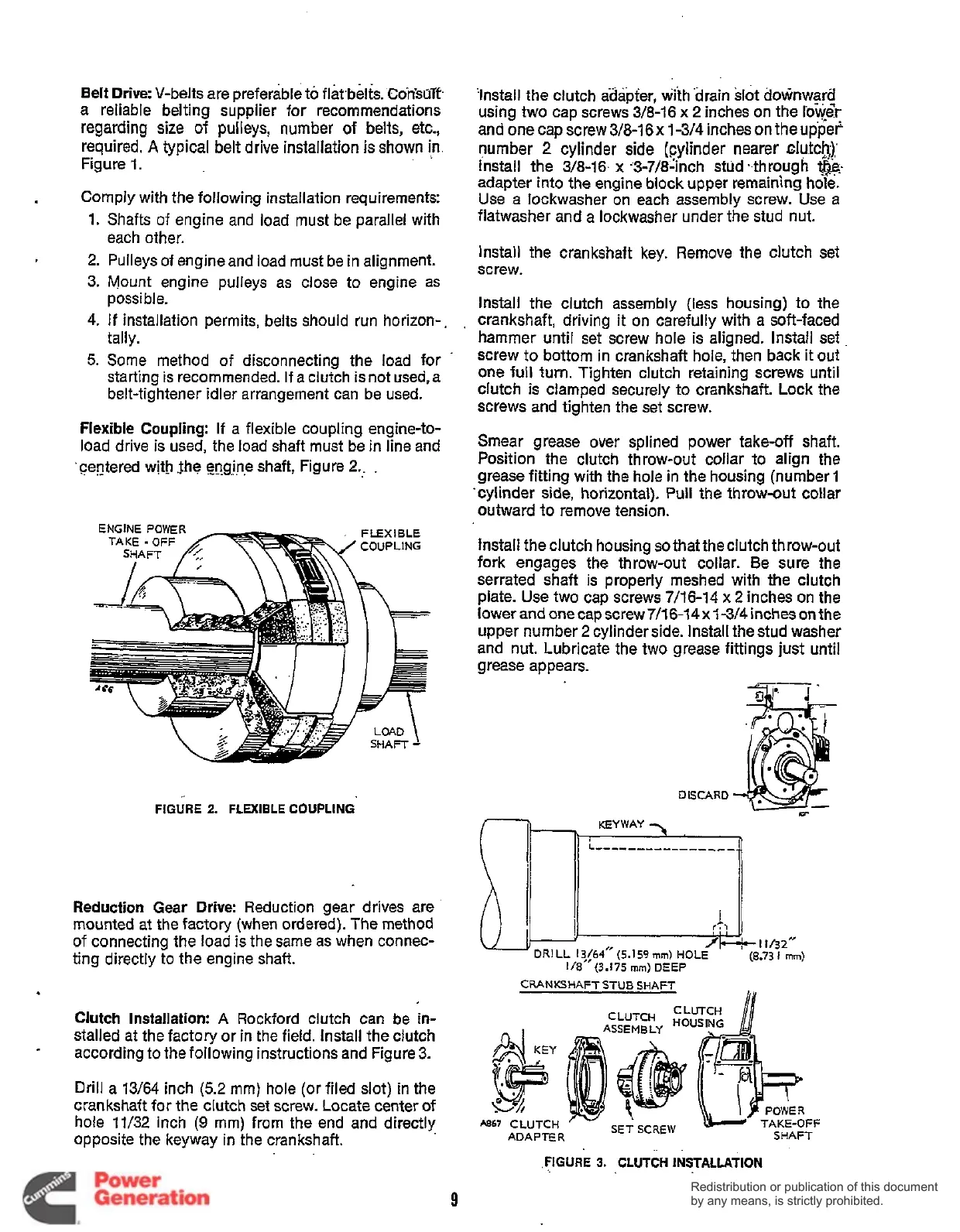

Flexible Coupling:

If a flexible coupling engine-to-

load drive is used, the load shaft must be

in

line and

‘centered with the eng-ine shaft, Figure 2..

.

each other.

ENGINE POWER

.

FLEXIBLE

FIGURE

2

FLEXIBLE COUPLING

Reduction Gear Drive:

Reduction gear drives are

mounted at the factory (when ordered). The method

of

connecting the load is the same as when connec-

ting directly

to

the engine shaft.

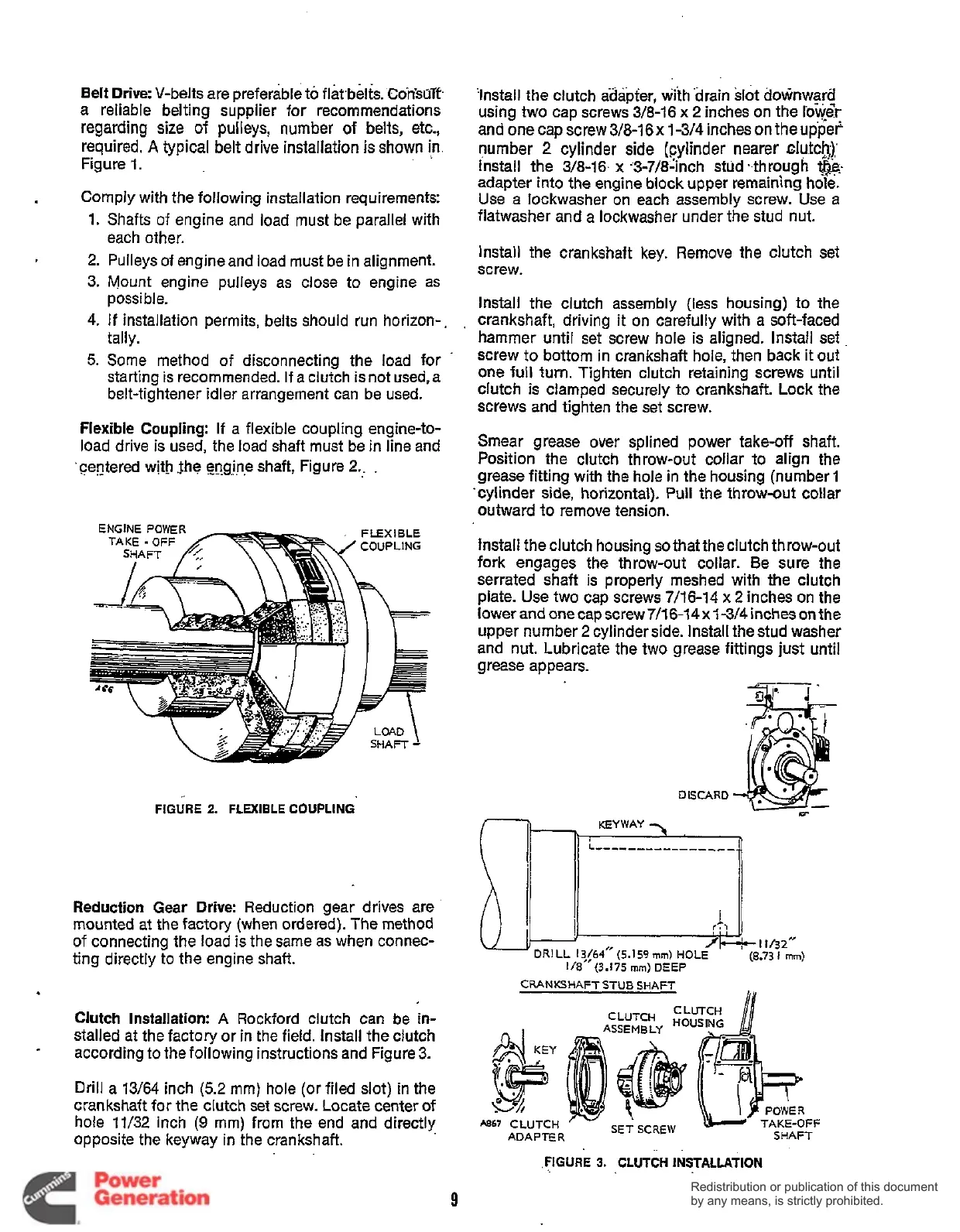

Clutch Installation:

A

Rockford clutch can be

in-

stalled at the factory or in the field. Install the clutch

according

to

the following instructions and Figure

3.

Drill a 13/64 inch

(5.2

mm) hole (or filed slot) in the

crankshaft for the clutch set screw. Locate center

of

hole 11/32 inch

(9

mm) from the end and directly

opposite the keyway in the crankshaft.

*

‘Install the clutch adapter, with drain slot downward

using two cap screws 3/8-16 x 2 inches on the

low&

and onecapscrew3/8-16~ 1-3/4inchesontheupper

number

2

cylinder side (Cylinder

nearer

~Iufck);

Install the 3/8-16. x ‘3-7/8‘inch stud .-through

t&:

adapter into the engine block upper remaining hole.

Use a lockwasher on each assembly screw. Use

a

flatwasher and a lockwasher under the stud nut.

Install the crankshaft key. Remove the clutch set

screw.

Install the clutch assembly (less housing) to the

crankshaft, driving it on carefully with a soft-faced

hammer until set screw hole is aligned. Install set

screw to bottom in Crankshaft hole, then back it out

one full

turn.

Tighten clutch retaining screws until

clutch is clamped securely to crankshaft. Lock the

screws and tighten the set screw.

Smear grease over splined power take-off shaft.

Position the clutch throw-out collar to align the

grease fitting with the hole in the housing (number

1

‘cylinder side, horizontal). Pull the throw-out collar

outward to remove tension.

Install the clutch housing

so

that

the

clutch throw-out

fork engages the throw-out collar. Be sure

the

serrated shaft is properly meshed with the clutch

plate. Use two cap screws 7/16-14 x

2

inches on the

lower

and

onecapscrew7/1&14~1-3/4inchesonthe

upper number

2

cylinder side. Install the stud washer

and nut. Lubricate the two grease fittings just until

grease appears.

DISCARD

f

n

I

n

KEYWAY

3

CRANKSHAFT STUB SHAFT

IIY

CLUTCH

CLUTCH

HOUSING

ASSEMBLY

TAKE-OFF

SHAFT

SET SCREW

A867

CLUTCH

ADAP‘IE

R

..

.

.FIGURE

3.

CLUTCH

INSTALLATION

9

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...