The overrunning clutch is packed in a special high

melting point grease and after its initial assembly,

needs no further lubrication. This clutch prevents the

engine from turning the starter motor at too high a

speed once it is started.

Do

not subject the overrun-,

ning clutch to grease dissolving or high temperature

cleaning methods. This may cause the clutch to lose

some or all of its grease.

If the pinion does not turn freely in the clutch in the

overrunning direction, or the clutch tends to slip in

the opposite direction, replace the assembly.

A

worn

clutch indicated by excessive looseness of the pinion

req u

i

res replacement.

Never attempt to repair or relubricate a defective clutch.

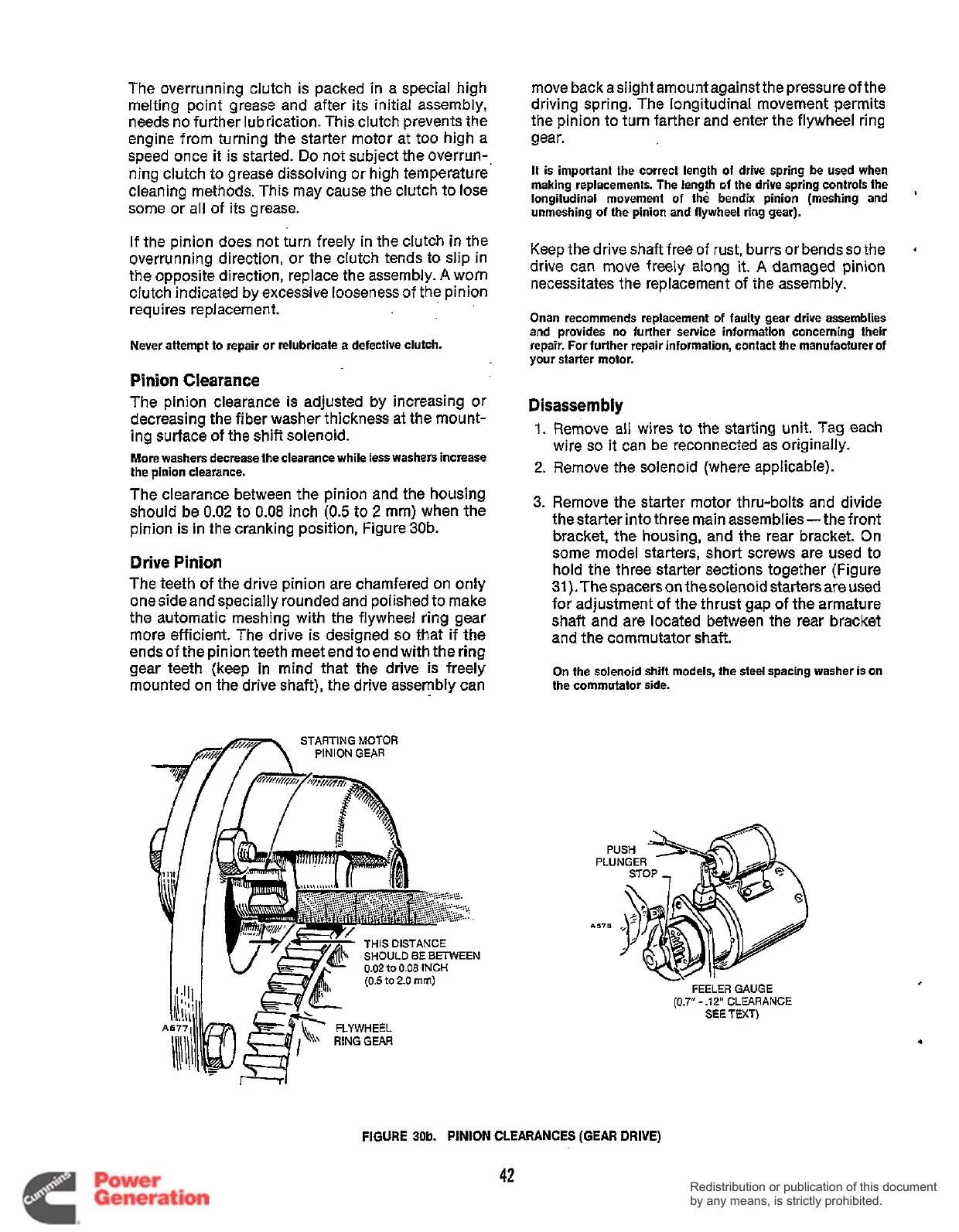

Pinion Clearance

The pinion clearance is adjusted by increasing or

decreasing the fiber washer thickness at the mount-

ing surface of the shift solenoid.

More washers decrease the clearance while less washers increase

the pinion clearance.

The clearance between the pinion and the housing

should be

0.02

to

0.08

inch

(0.5

to

2

mm) when the

pinion is in the cranking position, Figure 30b.

Drive

Pinion

The teeth of the drive pinion are chamfered on only

one side and specially rounded and polished to make

the automatic meshing with the flywheel ring gear

more efficient. The drive

is

designed

so

that if the

ends of the pinion teeth meetend toend with the ring

gear teeth (keep in mind that the drive is freely

mounted on the drive shaft), the drive assembly can

STARTING

MOTOR

flm

PINION

GEAR

SHOULD

BE BEMlEEN

0.02

to

0.08

INCH

move back aslight amount againstthe pressureof the

driving spring. The longitudinal movement permits

the pinion to turn farther and enter the flywheel ring

gear.

It is important the correct length of drive spring be used when

making replacements. The length of the drive spring controls the

longitudinal movement

of

the bendix pinion (meshing and

’

unmeshing of the pinion and flywheel ring gear).

Keep the drive shaft free of rust, burrs or bendsso the

drive can move freely along

it.

A

damaged pinion

necessitates the replacement of the assembly.

4

Onan recommends replacement of faulty gear drive assemblies

and provides no further service information concerning their

repair.

For

further repair information, contact the manufacturer

of

your starter motor.

Disassembly

1.

Remove all wires to the starting unit. Tag each

2.

Remove the solenoid (where applicable).

wire

so

it

can be reconnected as originally.

3.

Remove the starter motor thru-bolts and divide

the starter into three main assemblies- the front

bracket, the housing, and the rear bracket. On

some model starters, short screws are used to

hold the three starter sections together (Figure

31).The spacers on the solenoid starters are used

for adjustment of the thrust gap of the armature

shaft and are located between the rear bracket

and the commutator shaft.

On the solenoid shift models, the steel spacing washer is on

the commutator side.

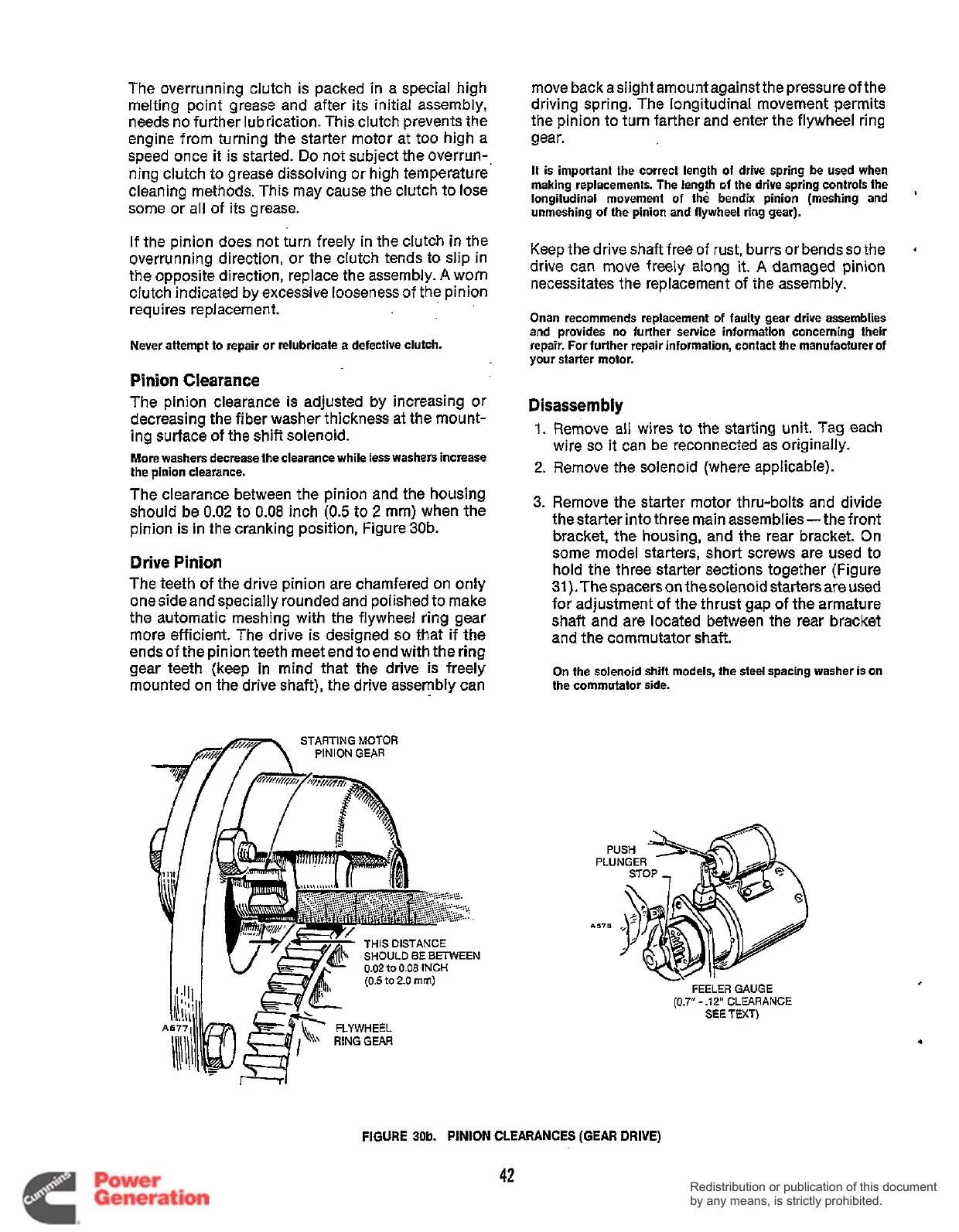

FEELER

GAUGE

(0.7”

-

.12”

CLEARANCE

SEETEXT)

.

FIGURE

30b.

PINION

CLEARANCES

(GEAR

DRIVE)

42

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...