L

Y

I

.I

FIGURE

55.

HONING CYLINDER

HONING

PROCEDURE

1.

2.

3.

4.

5,

6.

-

I

A

hone can be used to rebore a cylinder, Figure

55.

Remove stock to

0.002

inch

(0.051

mm) less

than finished bore with coarse hone

(100

grit),

then complete honing with finish hones (300grit).

Anchor block solidly foreither vertical or horizon-

tal

honing.

Use

either a drill press or heavy-duty

drill which operates at about

250.

to

450

rpm.

Lower hone into cylinder until it protrudes

1/2

to

3/4

inch

(1

3

to

19

mrn) past end of cylinder. Rotate

adjusting nut until stones come in contact with

cylinder wall at narrowest point.

Loosen adjusting nut until hone can be turned by

hand.

Connect drill to honeand start drill. Move hone up

and down in the cylinder about

40

cycles per

minute. Usually the bottom

of

the cylinder must

be worked out first because it

is

smaller. When

cylinder takes a uniform diameter, move hone up

and down all the way through the bore. Follow the

hone manufacturer’s recommendations for wet or

dry honing and oiling the hone.

Check diameter of cylinder regularly during hon-

ing.

A

dial bore gauge is the easiest method but a

telescoping gauge can be used. Check

the

size at

six

places in the bore: measure twice at the top,

middle and bottom at

90

degree angles.

.

When the cylinder is about

0.002

inch

(0.051

mm)

within the desired bore, change to finestones and

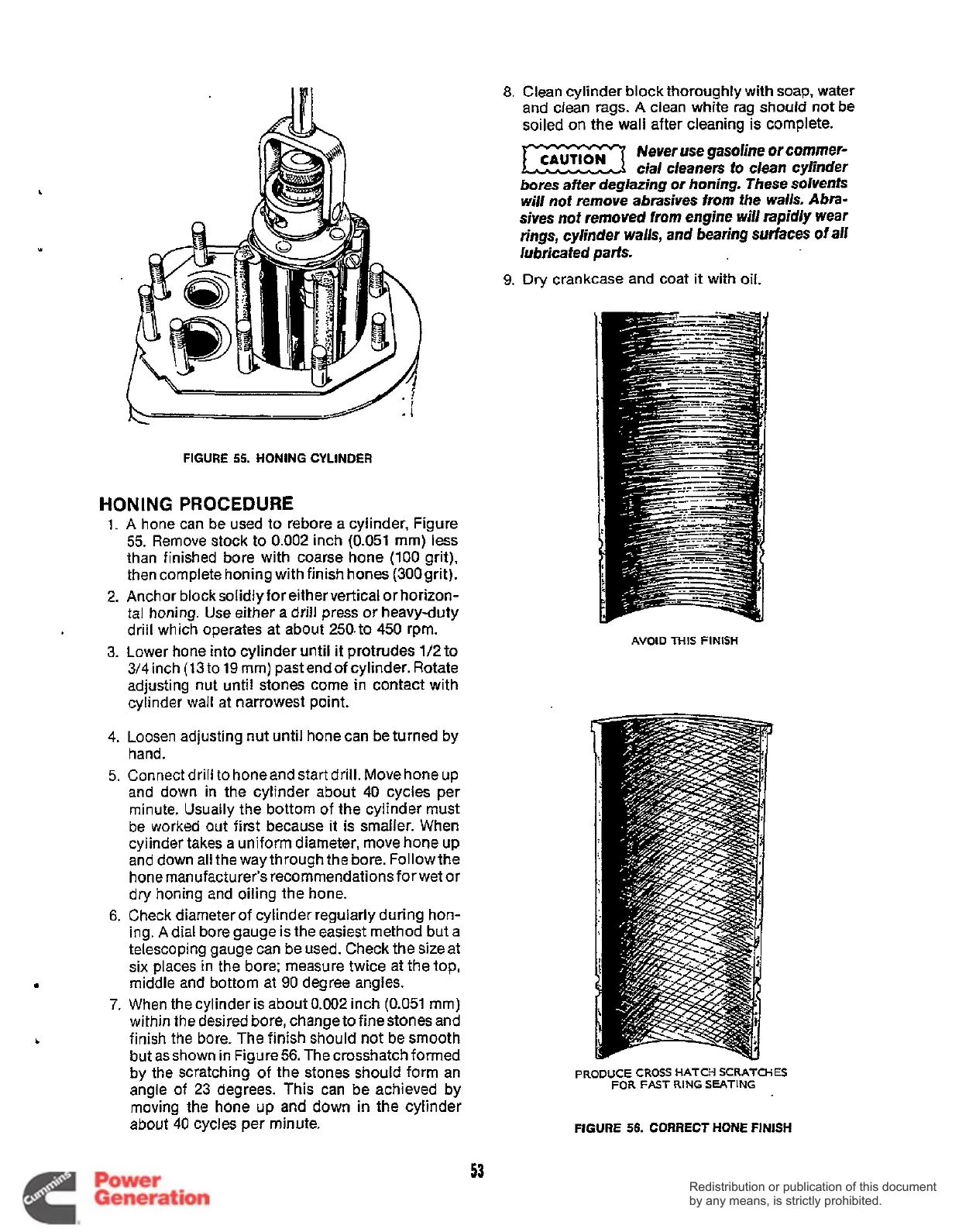

finish the bore. The finish should not be smooth

but as shown in Figure

56.

The crosshatch formed

by the scratching of the stones should form an

angle of 23 degrees. This can be achieved by

moving the hone

up

and down in the cylinder

about

40

cycles per minute.

8.

Clean cylinder block thoroughly with soap,

water

and clean

rags.

A

clean white rag should not be

soiled on the

wall

after cleaning

is

complete.

Never use gasoline

or

commer-

cial cleaners to clean cylinder

bores after degiazing or honing. These solvents

will

not

remove abrasives

from

the walls. Abra-

sives

not

removed from engine will rapidly wear

rings, cylinder walls, and bearing surfaces of all

lubricated

parts.

9.

Dry crankcase and coat it with oil.

AVOID

THIS

FINISH

PRODUCE

CROSS

HATCH

SCRATCHES

FOR

FAST

RING

SEATING

FIGURE

56.

CORRECT

HONE FINISH

53

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...