I

FIGURE 43.

TIMING

GEAR REMOVAL

AND

INSTALLATION

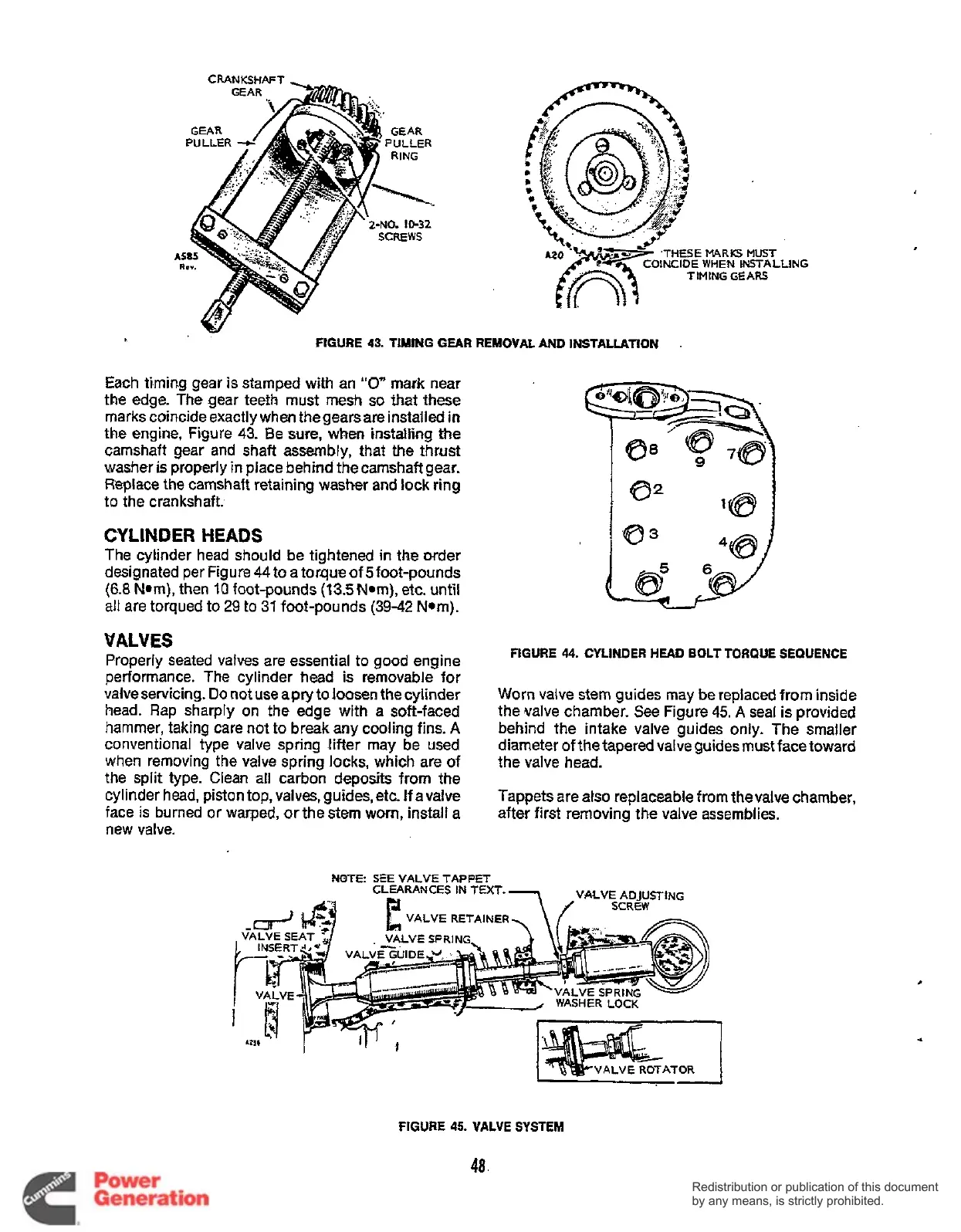

Each timing gear

is

stamped with an

"0"

mark near

the edge. The gear teeth must

mesh

so

that these

marks coincide exactly when thegears are installed

in

the

engine, Figure

43.

Be

sure,

when

installing the

camshaft gear and shaft assembly, that the thrust

washer

is

properly in place behind thecamshaft gear.

Replace the camshaft retaining washer and lock ring

to

the crankshaft.

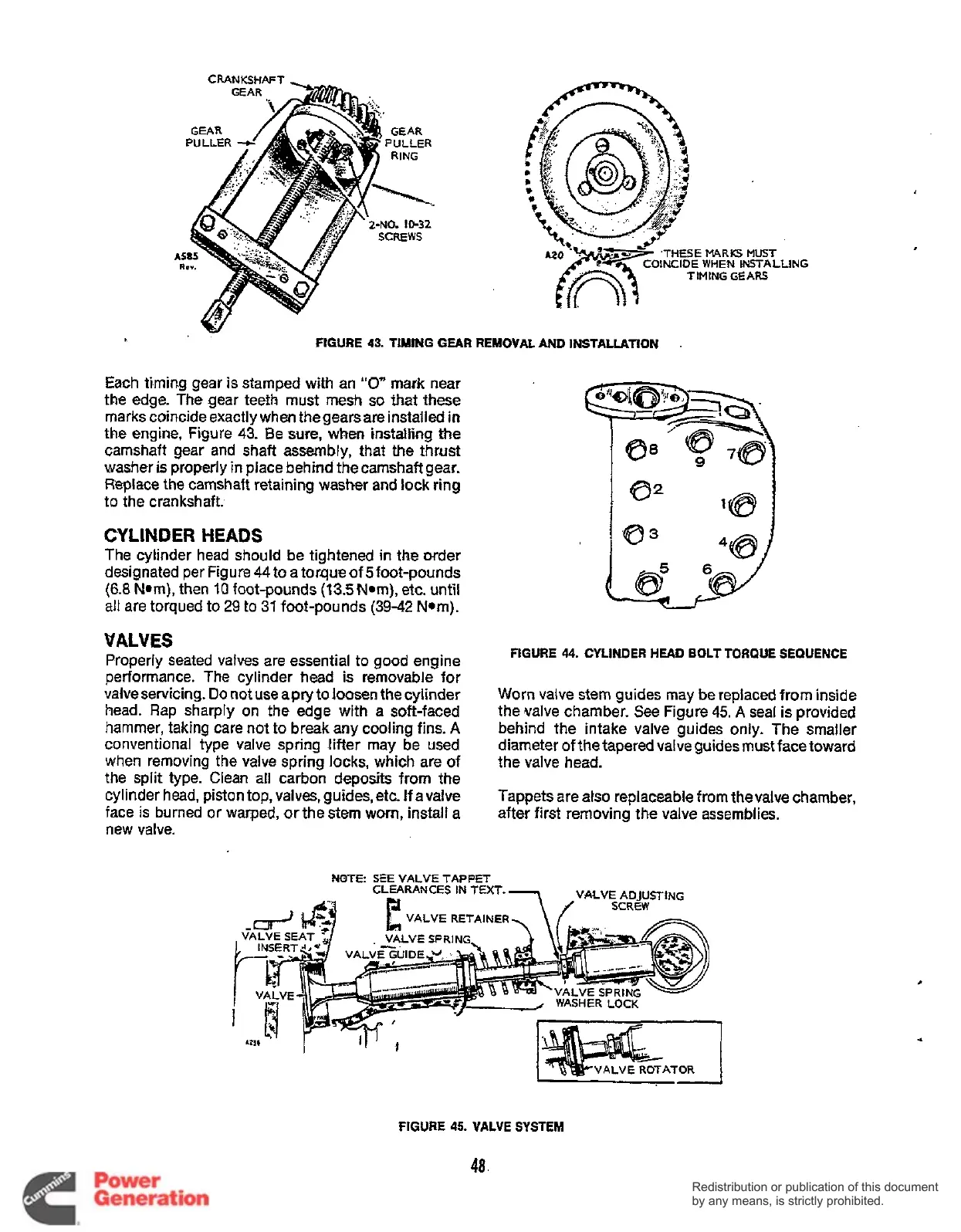

CYLINDER HEADS

The cylinder head

should

be tightened

in

the order

designated per Figure 44to a torqueof 5foot-pounds

(6.8

Nom), then

10

foot-pounds (13.5N.m). etc. until

all

are torqued to

29

to

31

foot-pounds

(39-42

Nom).

VALVES

Properly seated valves are essential to good engine

performance. The cylinder head

is

removable for

vaiveservicing.

Do

not use apry to

loosen

the cylinder

head. Rap sharply on the edge with a soft-faced

hammer, taking care not

to

break any cooling fins.

A

conventional type valve spring litter may be used

when removing the valve spring locks, which are of

the split type. Clean all carbon deposits from the

cylinder head, piston top, valves, guides, etc.

If

avalve

face is burned

or

warped, or the stem

worn,

install a

new valve.

FIGURE

44.

CYLINDER

HEAD

BOLT

TORQUE SEQUENCE

Worn valve stem guides may be replaced from inside

the valve chamber. See Figure

45.

A

seal is provided

behind the intake valve guides only. The smaller

diameter of the tapered valve guides must face toward

the valve head.

Tappets are atso replaceable from thevalve chamber,

after first removing the valve assemblies.

NOTE

SEE VALVE

TAPPET

CLEARANCES

IN

TEXT

VALVE

RETAINE

CLEARANCES

IN

TEXT

VALVE

RETAINE

FIGURE

45.

VALVE

SYSTEM

48.

Redistribution or publication of this document

by any means, is strictly prohibited.

Redistribution or publication of this document

by any means, is strictly prohibited.

Loading...

Loading...