Section 6

Frame Modifications

FRAME MODIFICATIONS

INTRODUCTION

Peterbilt offers customer specified wheelbases and frame overhangs. So, in most cases frame modifications

should not be necessary.

However, some body installations may require slight modifications, while other installations will require

extensive modifications. Sometimes an existing dealer stock chassis may need to have the wheelbase changed

to better fit a customer’s application. The modifications may be as simple as modifying the frame cutoff, or as

complex as modifying the wheelbase.

DRILLING RAILS

If frame holes need to be drilled in the rail, see SECTION 4 BODY MOUNTING for more information.

MODIFYING FRAME LENGTH

The frame overhang after the rear axle can be shortened to match a particular body length. Using a torch is

acceptable; however, heat from a torch will affect the material characteristics of the frame rail. The affected

material will normally be confined to within 1 to 2 inches (25 to 50mm) of the flame cut and may not adversely

affect the strength of the chassis or body installation.

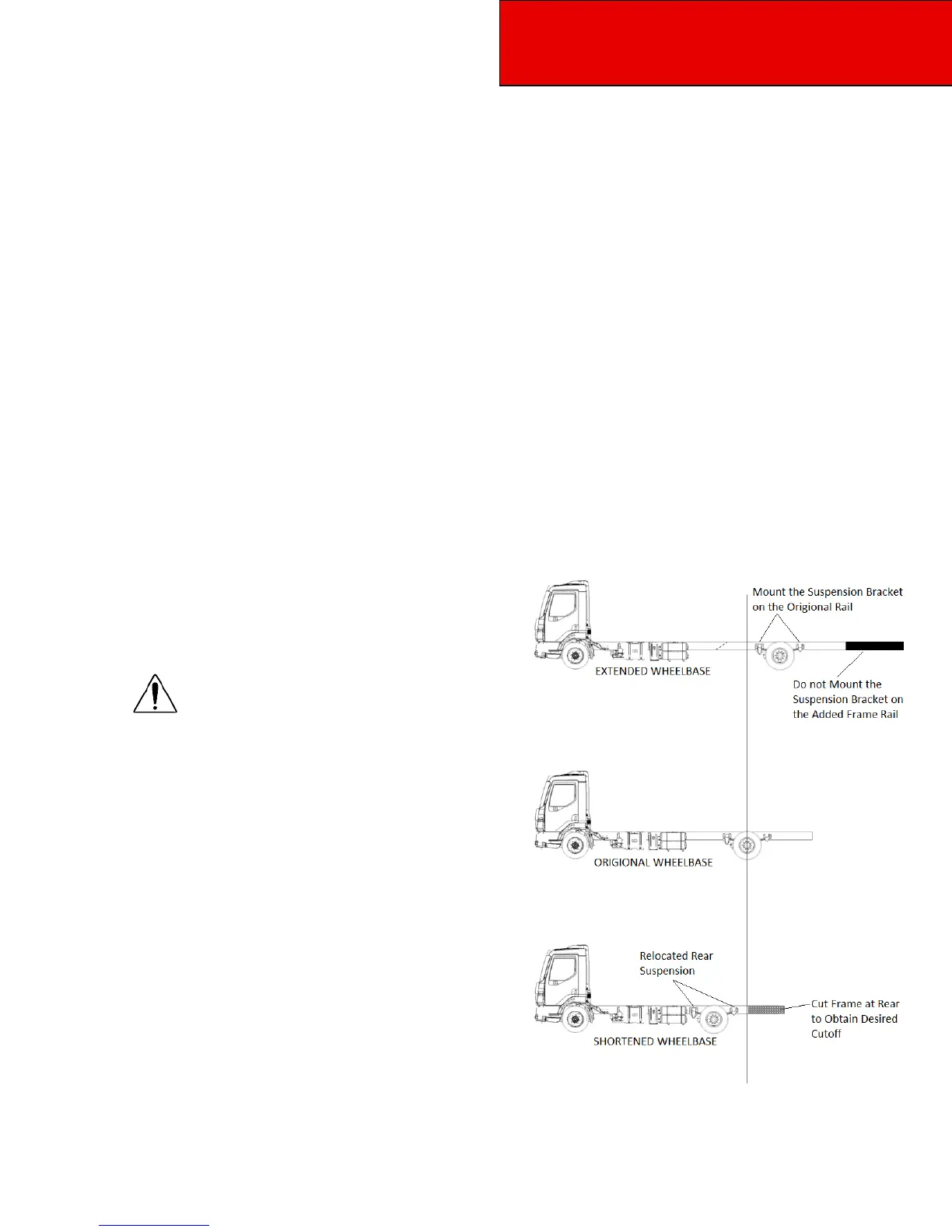

CHANGING WHEELBASE

Changing a chassis’ wheelbase is not recommended.

Occasionally, however, a chassis wheelbase will need to

be shortened or lengthened. Before this is done there are a

few guidelines that should to be considered.

WARNING! When changing the wheelbase,

be sure to follow the driveline

manufacturer’s recommendations for

driveline length or angle changes.

Incorrectly modified drivelines can fail

prematurely due to excessive vibration.

This can cause an accident and severe

personal injury.

Before changing the wheelbase, the driveline angles of the

proposed wheelbase need to be examined to ensure no

harmful vibrations are created. Consult with the driveline

manufacturer for appropriate recommendations.

Before the rear suspension is relocated, check the new

location of the spring hanger brackets. The new holes for

the spring hanger brackets must not overlap existing holes

and should adhere to the guidelines in the “FRAME

DRILLING” section of this manual.

When shortening the wheelbase, the suspension should be

moved forward and relocated on the original rail. The rail

behind the suspension can then be cut to achieve the

desired frame overhang. See FIGURE 6-1.

Loading...

Loading...