7.4

Section 7

TroubleshooTing

Pinnacle Operators Manual

Pickering Laboratories Inc.

COMMON SYSTEM PROBLEMS continued

continued

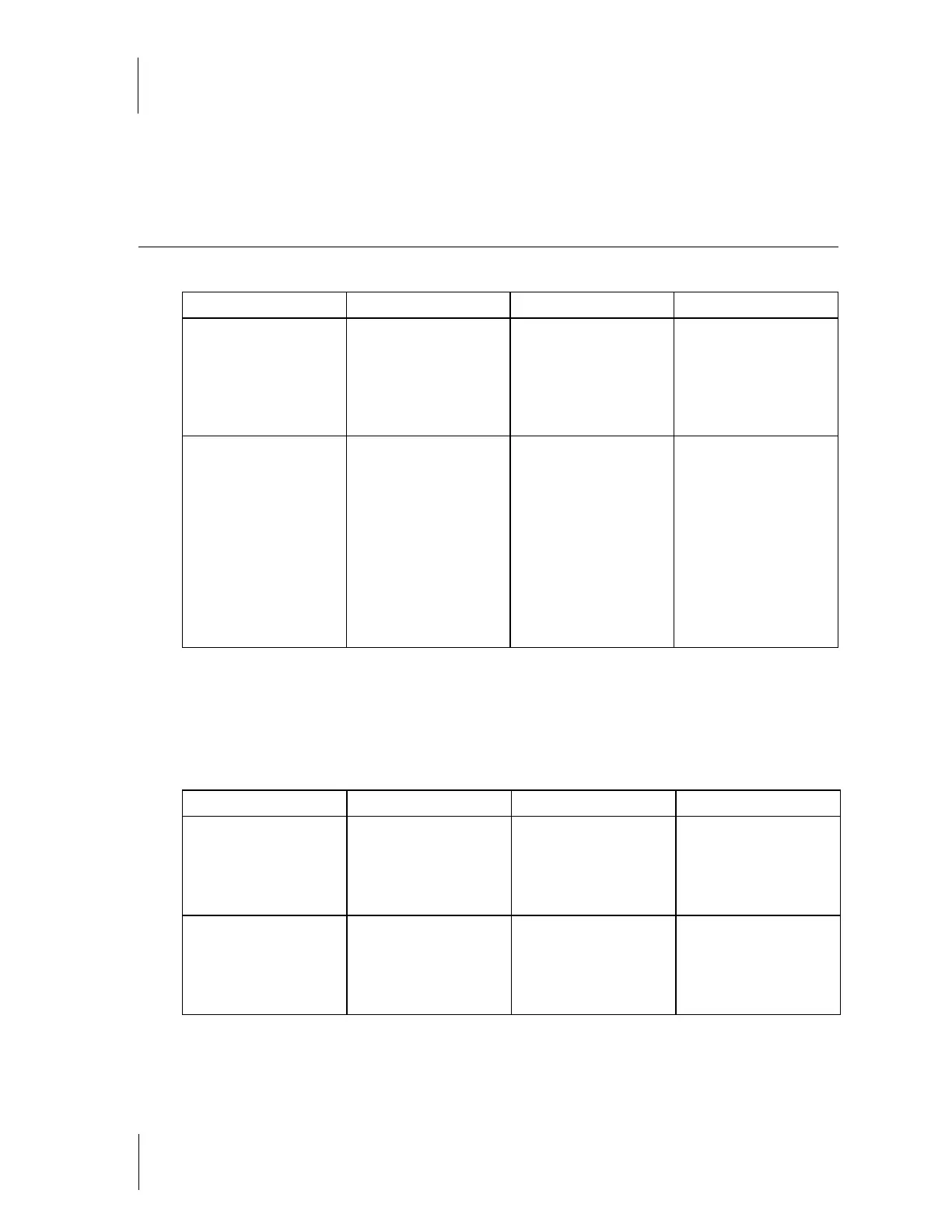

OBSERVED PROBLEM COMMON CAUSE ACTION TO TAKE NOTES

Over-pressure relief valve is opened There is a blockage in the system Determine the exact location of the

blockage.

Disconnect one fitting at a time,

moving backward from the back-

pressure regulator end, until the

pressure drops

Flush the system with solvent/water

until pressure drops, or replace

appropriate part

Blocked Heated Reactor reactor Improper Shutdown

Dissolved silica precipitating in the

reactor

Contaminated reagents

Mineral deposits from hard-water

samples or reagents

Greasy samples

Use of calcium hypochlorite

Home-made reagents

Hydrindantin deposits from Expired

TRIONE

Follow the procedure for removing

mineral deposits on Page 7.8

Follow the procedure for removing

Silica deposits on Page 7.8

Replace heated reactor if flushing does

not help

Silica from NaOH backflow onto

column

Use of calcium hypochlorite as the

oxidant in glyphosate determination

Preparing your own reagents with

poor quality chemicals

COMMON CHROMATOGRAPHY PROBLEMS

When having chromatography problems collect 2-3 chromatograms that show the problem. Fax these and most

recent normal one to Pickering Laboratories at (650) 968-0749.

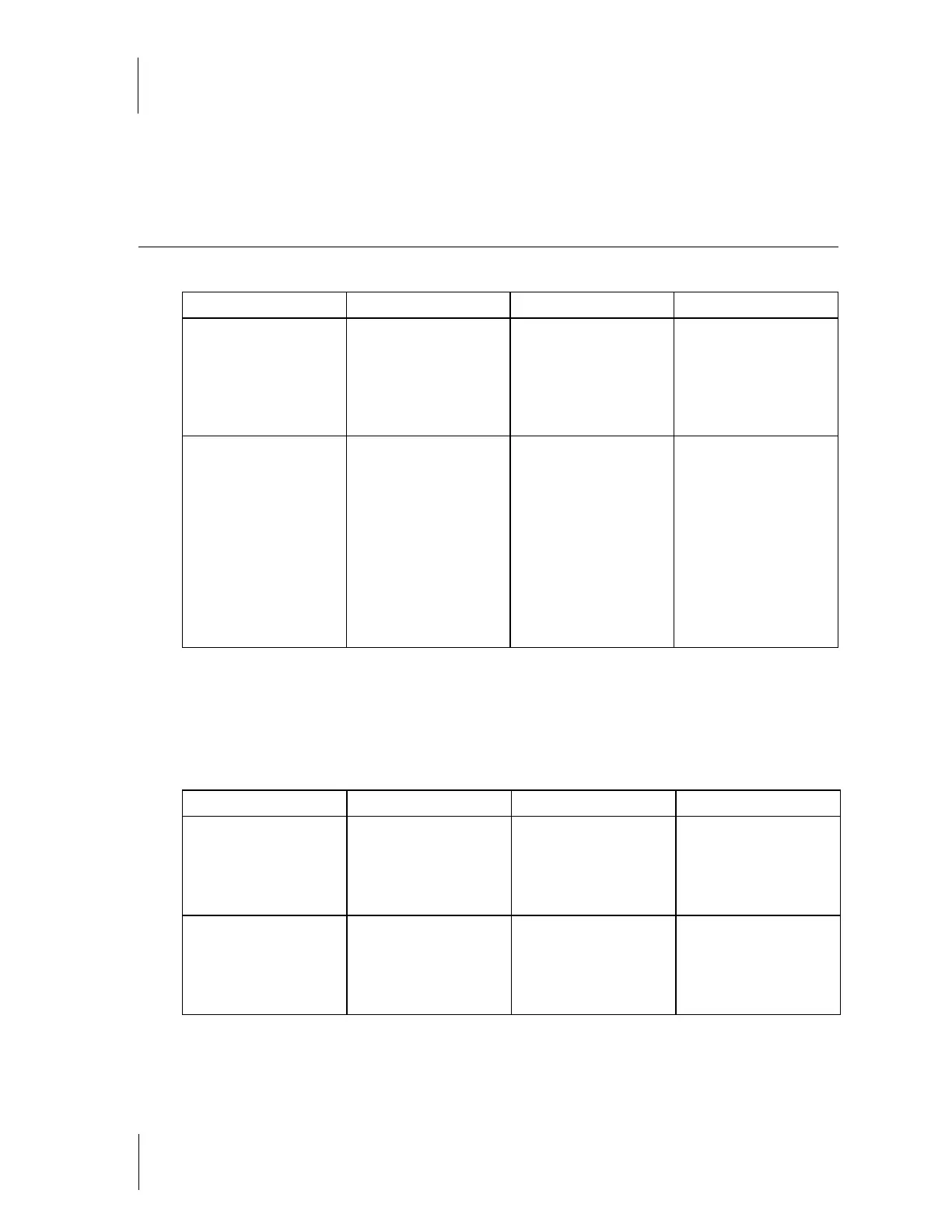

OBSERVED PROBLEM COMMON CAUSE ACTION TO TAKE NOTES

High Background Signal Contaminated Eluant

Bacterial Growth

Fingerprints

Contaminated Reagent(s)

Defective chemicals

Flush HPLC system and Pinnacle PCX

with 80/20 Water/MeOH

Put new eluants on HPLC, make new

reagents

Noisy Baseline Worn pump seal

Detector noise

Chemical contamination

Reagent too old

Check for pattern in the noise.

If the background signal is also

elevated, check for chemical

contamination, or an error in

formulation

Match the frequency of the noise to

one of the pumps.

If the noise is random, check the

detector

Loading...

Loading...