PreciseFlex_Robot

106

5. Measure the belt tension, every 10 degrees of rotation of the gripper to find the minimum tension.

6. Adjust the minimum belt tension to the value in Appendix E. This may be possible by just

releasing and re-tightening the Motor Locking Screws. It may require adjusting the Belt Tension

Screw. For some earlier robots, the 18mm M4 belt tension screw may need to be replaced with a

longer 20, 22, or 24mm M4 Socket Head Cap Screw in order to get enough tension.

7. Tighten the 2 motor locking screws again.

8. For robots shipped after April 2012, an access hole has been cut in the J4 belt cover so that the

tension meter head can reach the timing belt without tipping up the belt cover.

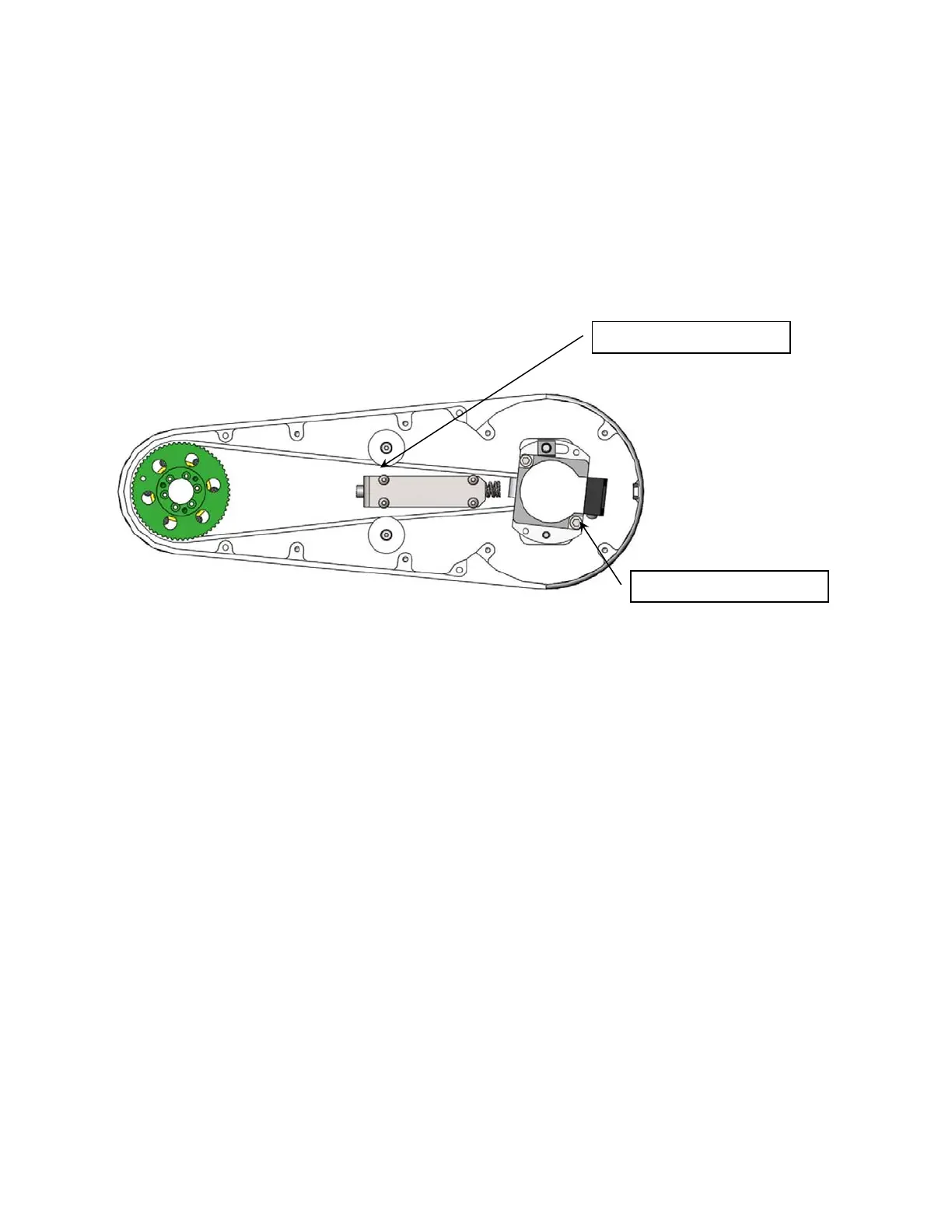

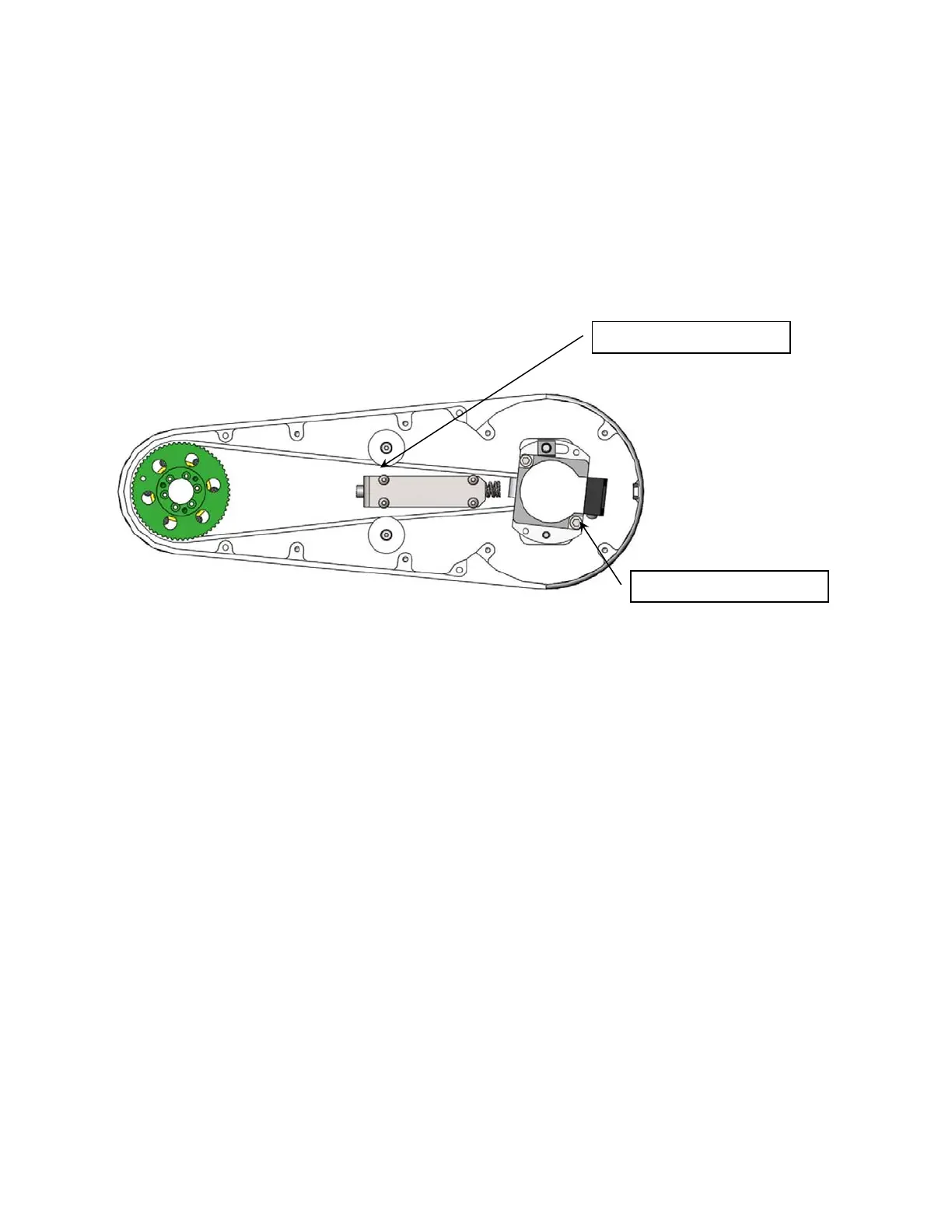

Tensioning the J3 and J4 Belts (2014)

In 2014 the access hatches shown below were added to both the inner and outer links to facilitate belt

tensioning. Once the hatch cover is removed, loosen the appropriate motor locking screws one turn to

unclamp the motor (do not loosen these screws more than one or two turns or the retaining nuts can fall

off inside the link), insert the microphone from the belt tension meter near the belt to measure belt tension

and adjust the M4 SHCS to adjust belt tension. Be sure to measure the belt tension 8 times, at 45

increments of the pulley in the axis rotation and set the tension at the position which has the lowest

tension. See Appendix E.

Belt Tension Screw

Motor Locking Screw

Loading...

Loading...