Introduction to the Hardware

21

Test Procedure for the PF400

The worst-case crash condition for the PF400 is when the Z axis is moving downwards at the 100%

speed of 500mm/sec and crashes into the relatively non-compliant hand of an operator pinching the hand

into a hard surface. A test setup to measure this force is shown below in Figure 4.

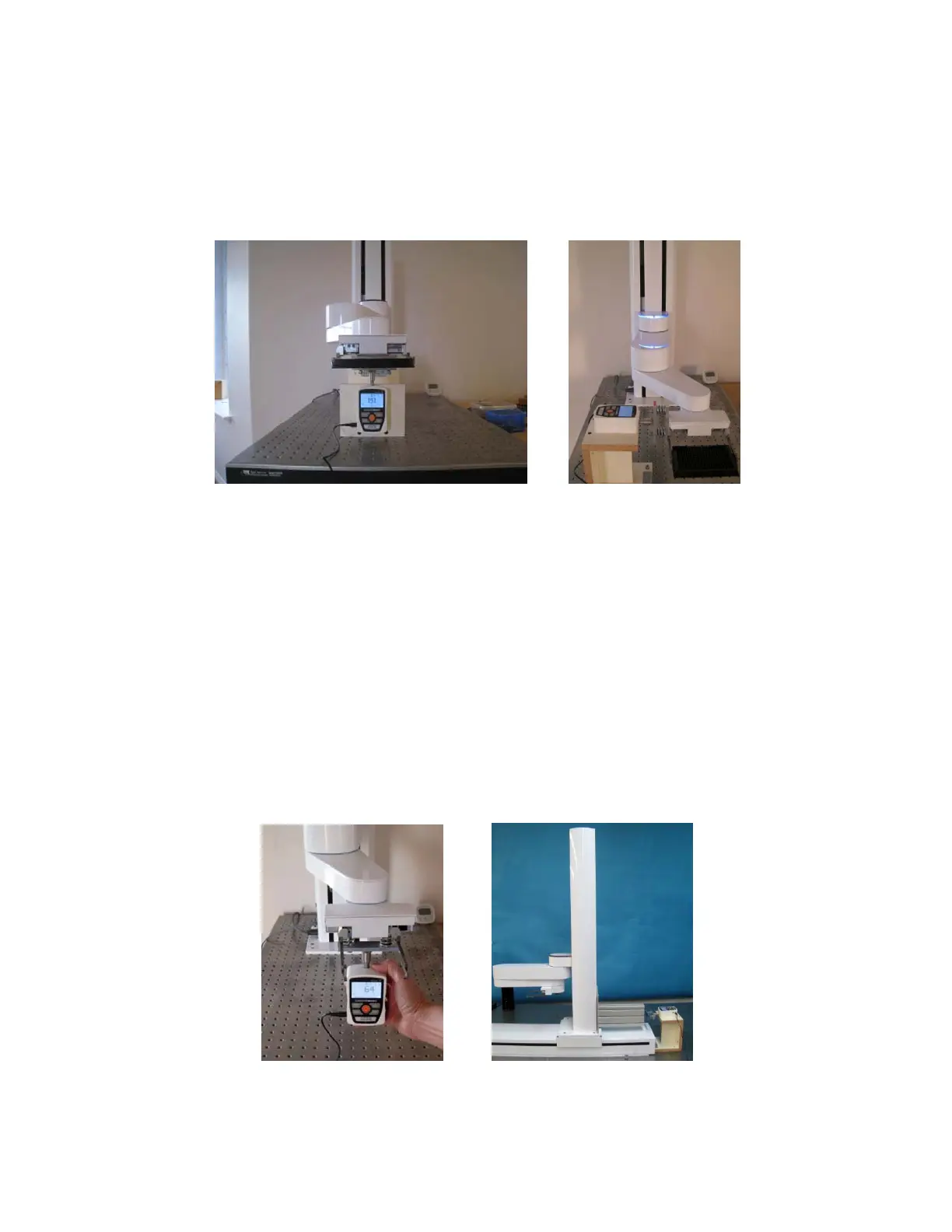

Figure 4: Vertical and Horizontal Test Setup

In this test setup a digital force gage (traceable to NIST standards) is mounted below (or to the left for

horizontal testing) of the gripper of the robot and a “hand compliance simulator” consisting of two plates

separated by compression springs with a compression constant of 75N/mm equal to the compression

constant of a human hand (from figure 2) is attached to the force gage. For the Z test the robot is driven

downwards in the Z direction at various speeds and crashes into the hand simulator attached to the force

gage. For the Horizontal tests the robot is driven horizontally at various speeds into the hand simulator.

A worse case horizontal crash is measured with arm at full extension and J2 (the shoulder) rotating the

arm at various speeds into the force gage. This data is shown under the “J2 rot” column.

A typical case of a robot contacting a person is bumping into the person in free space where the person is

not trapped against a hard surface, or where there is some distance between the person’s appendage

and the hard surface (for the PF400 any distance over 20mm is adequate for the person to stop the robot

with a force less than 40N in the horizontal plane and approximately 60N in the –Z direction.

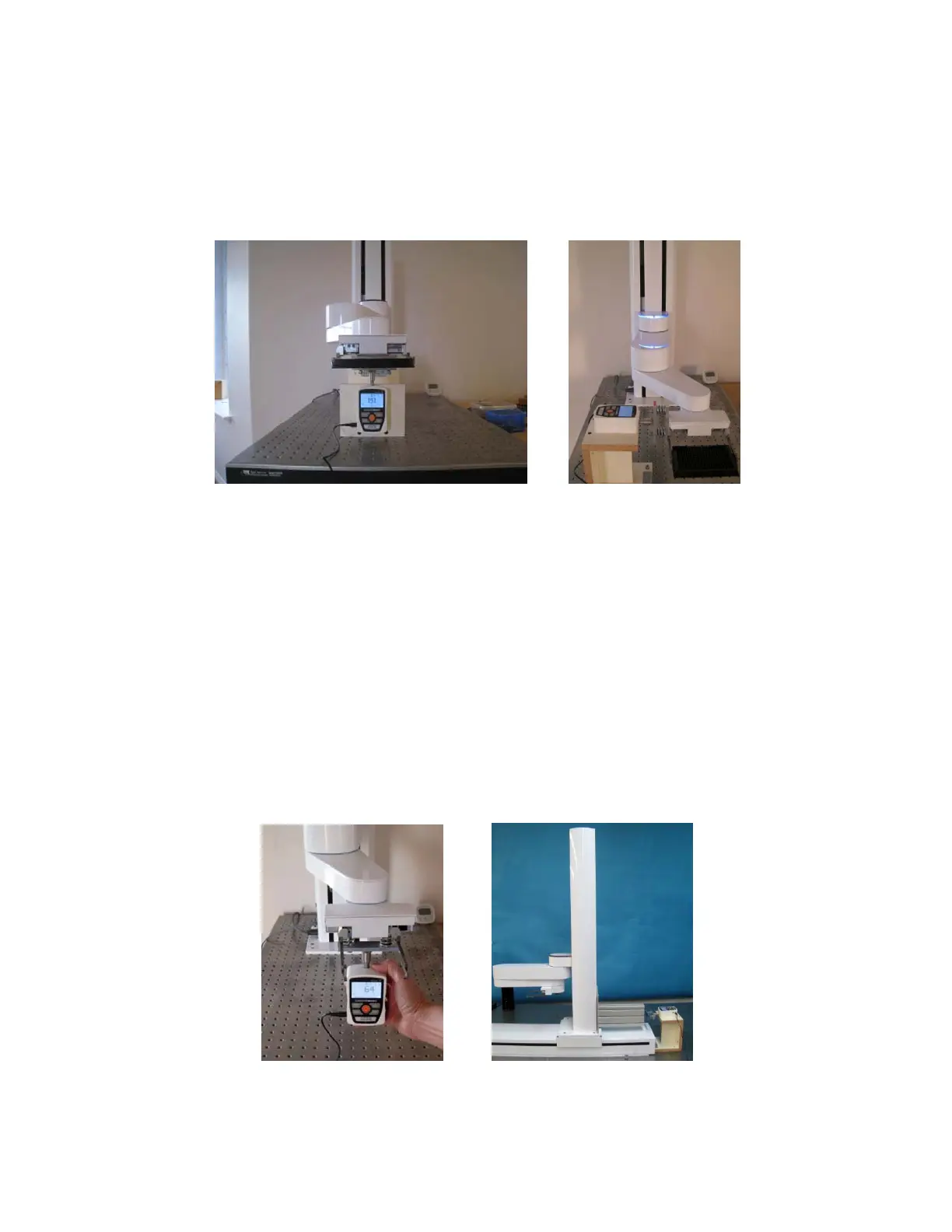

Figure 5: Free Space Collision Test and Linear Rail Test

Loading...

Loading...