The example is intended to provide the programmer with a couple of

“programming obstacles” that he might not immediately see:

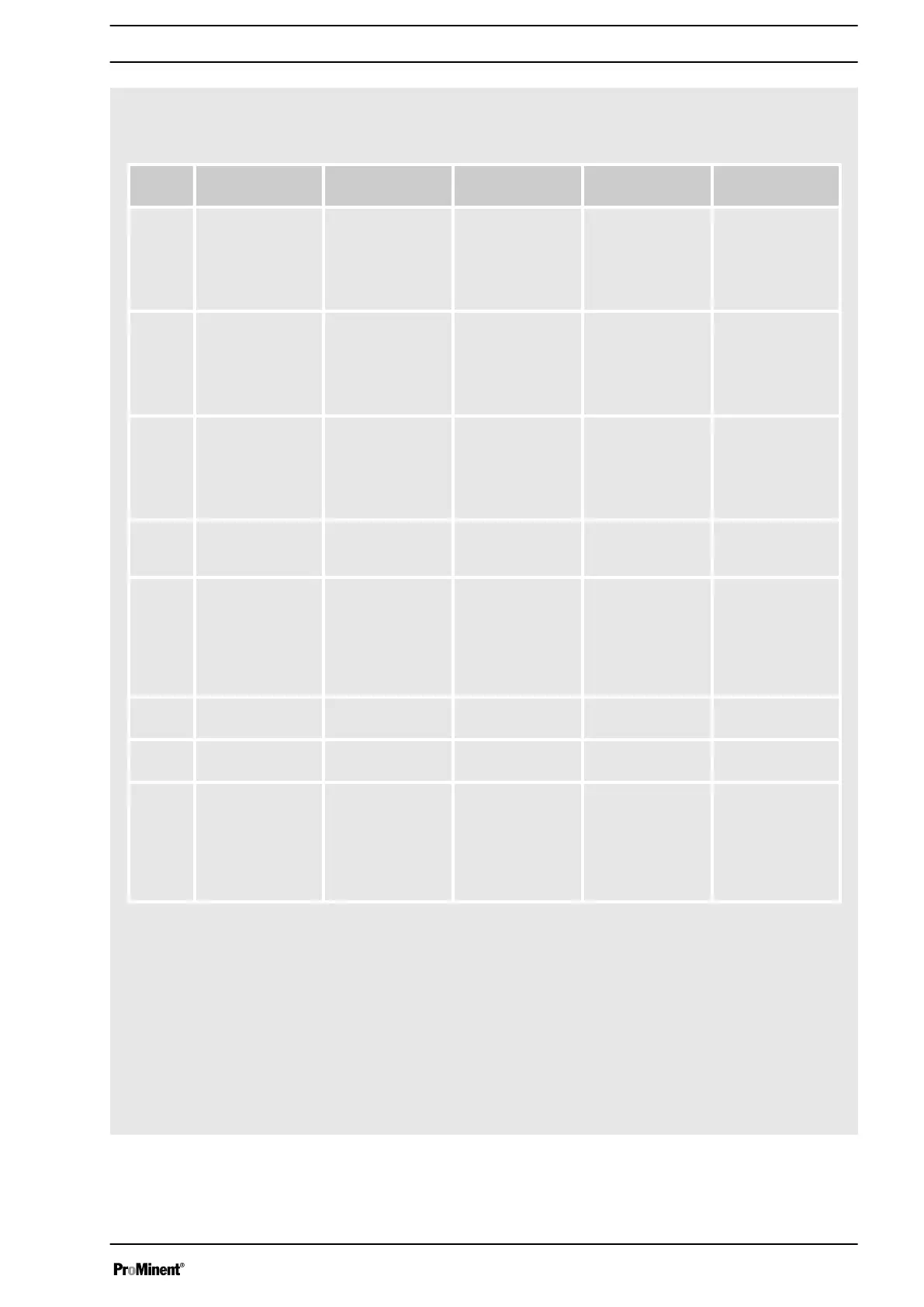

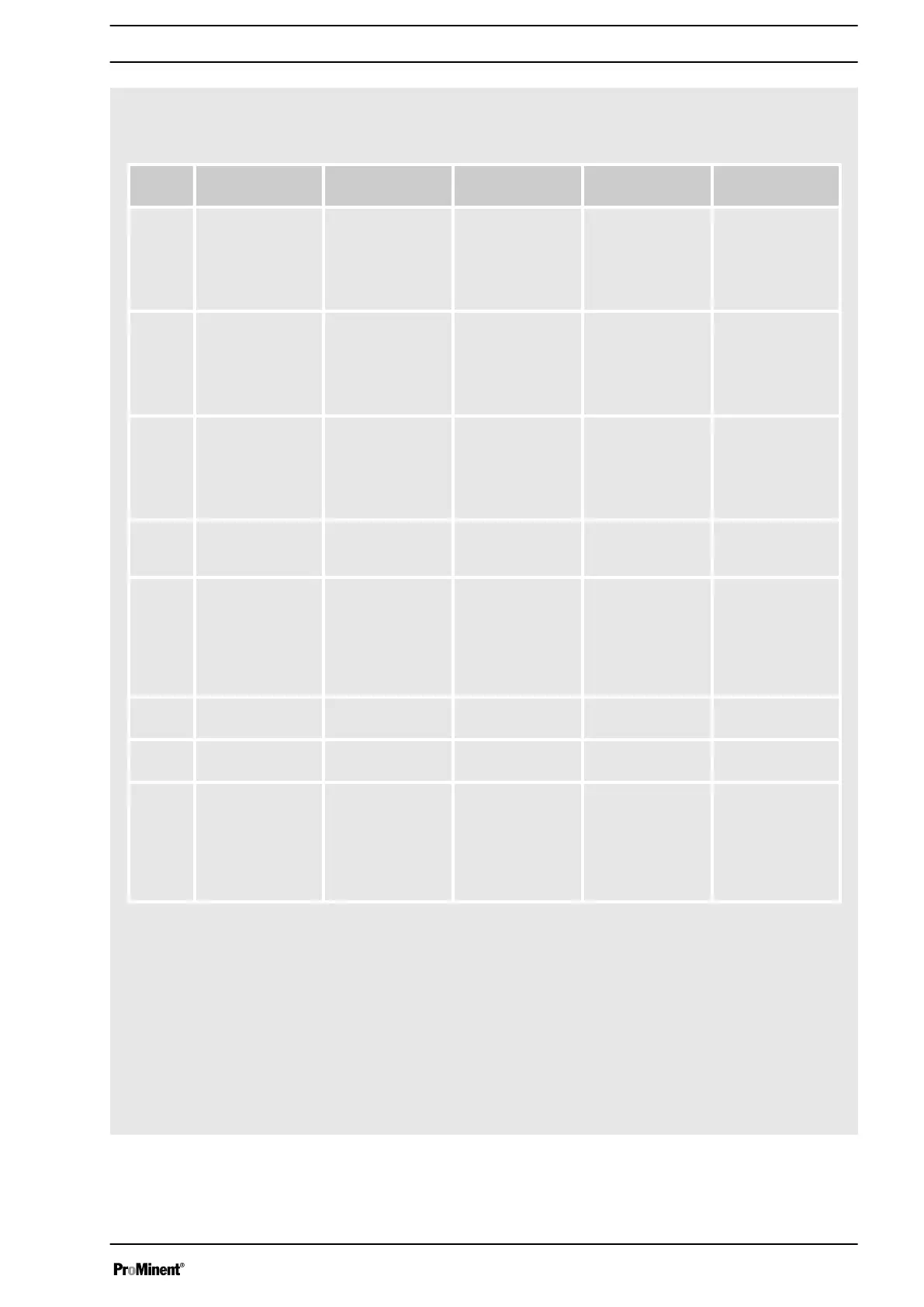

Com‐

mand

Time event Additional param‐

eter

Action Additional param‐

eter

Comment

01 Config I/O 1 Input, reacts when

closing

Start Delayer 1 When a contact

closes between

pins 1 and 4 at

“Config I/O” con‐

nector, this starts

delayer 1

02 Config I/O 1 Input, reacts when

closing

Start Delayer 2 When a contact

closes between

pins 1 and 4 at

“Config I/O” con‐

nector, this starts

delayer 2

03 Config I/O 1 Input, reacts when

closing

Start Delayer 3 When a contact

closes between

pins 1 and 4

“Config I/O” con‐

nector, this starts

delayer 3

04 Init Stop Pump stops as

soon as the timer

is activated

05 Delayer 1 after 60 sec Close Config I/O 2 Pins 2 and 4 of

the “Config I/O”

connector act like

a normally closed

contact – enabling

you to control a

device

06 Delayer 2 after 120 sec Manual 12,000 l/h and

80% stroke length

Pump runs after

120 s at 12 l/h

07 Delayer 3 after 180 sec Stop Pump stops after

180 s

08 Delayer 3 after 180 sec Open Config I/O 2 Pins 2 and 4 of

the “Config I/O”

connector act like

a normally open

contact – enabling

you to control a

device

Explanations:

n If 1 time event (trigger) is to trigger 3 actions that are to have

delays of different lengths, then you need to start 3 delayers and

not just 1 - see instructions 01 to 03.

n If several actions are to be performed after the same delay time,

then you need to write exactly as many instructions – with the same

time event (instructions 07 and 08).

n If, for example, you are using

‘Delayer 1’

-

‘60 s’

and

‘Delayer 1’

-

‘120 s’

, then the action is never performed after the second (longer

delay time because the delayer has been activated after the

smaller delay time and becomes inactive.

n Without

‘Init’

-

‘Halt’

(instruction 04) it would remain unclear

whether the pump alone runs by

‘Activation’

of the timer.

Example - to avoid errors

Set up /

‘Menu’

71

Loading...

Loading...