Process Control

G160/G161 6-6 SM

6.3 PROCESS CONTROL

6.3.1 OVERVIEW

This machine has the following two forms of process control:

Potential control

Toner supply control

Process control uses the following components:

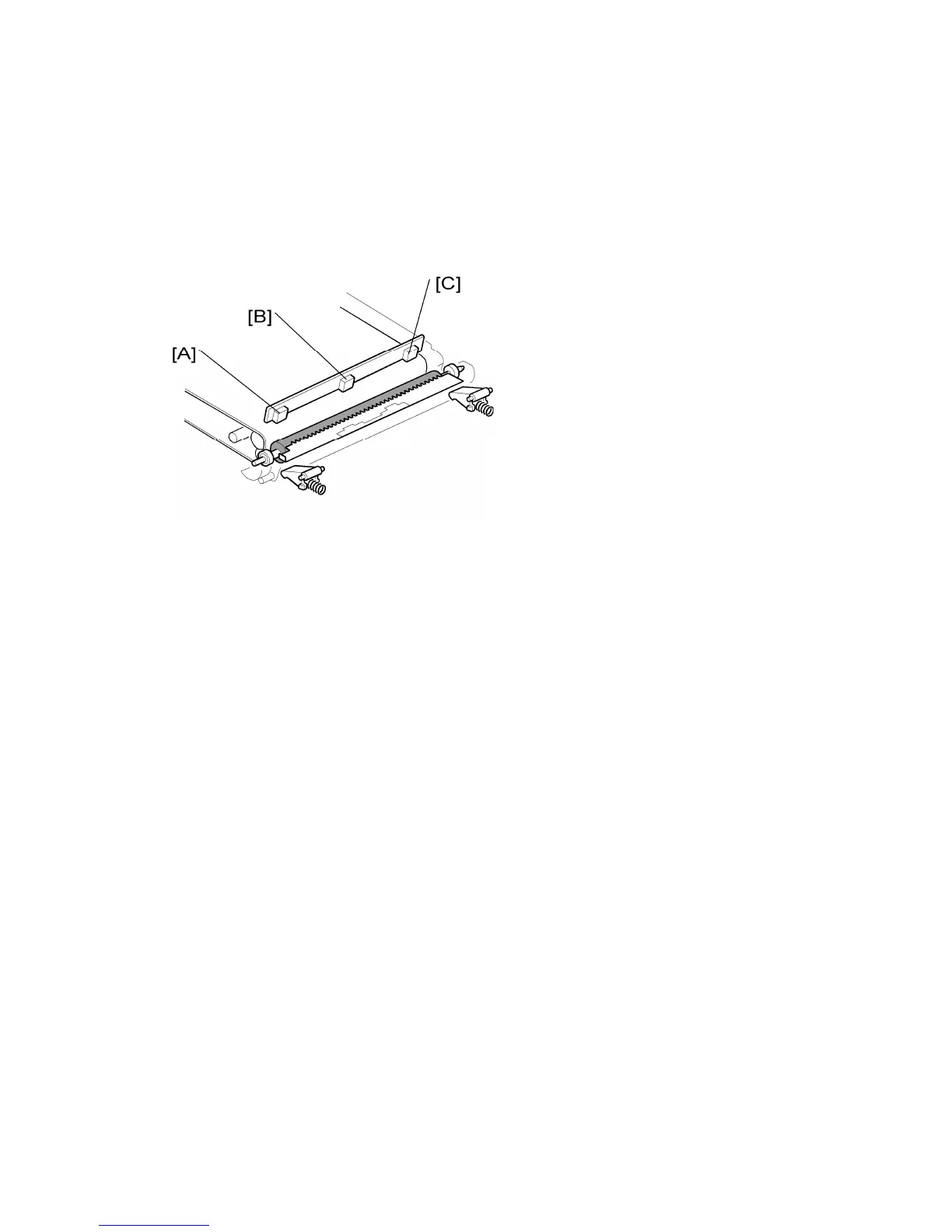

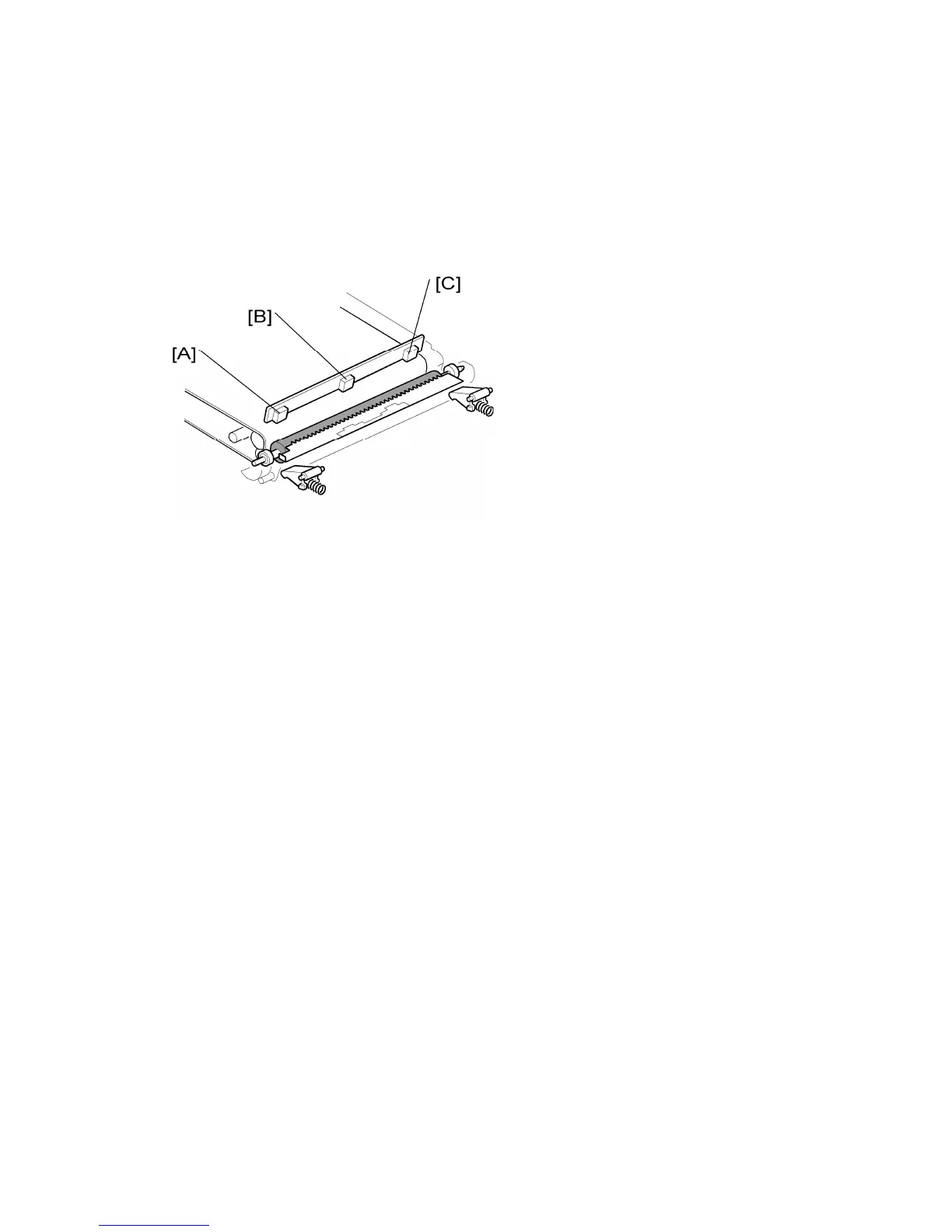

Three ID (image density) sensors (left [A], center [B], and right [C]). Only the center ID

sensor is used for process control. The left, center, and right ID sensors are used for

line positioning and other adjustments.

TD (toner density) sensor in each development unit.

6.3.2 POTENTIAL CONTROL

Overview

Potential control controls development to keep the toner images on the drums at the same

density. It does this by compensating for variations in drum chargeability and toner density.

The machine uses the ID sensor to measure the reflectivity of the transfer belt and the

density of a standard sensor pattern. This is done during the process control self-check.

The machine measures these values from the ID sensor output and a reference table in

memory.

V

D

: Drum potential without exposure – to adjust this, the machine adjusts the charge

roller voltage.

V

B

: Development bias

V

L

: Drum potential at the strongest exposure – to adjust this, the machine adjusts the

laser power.

Loading...

Loading...