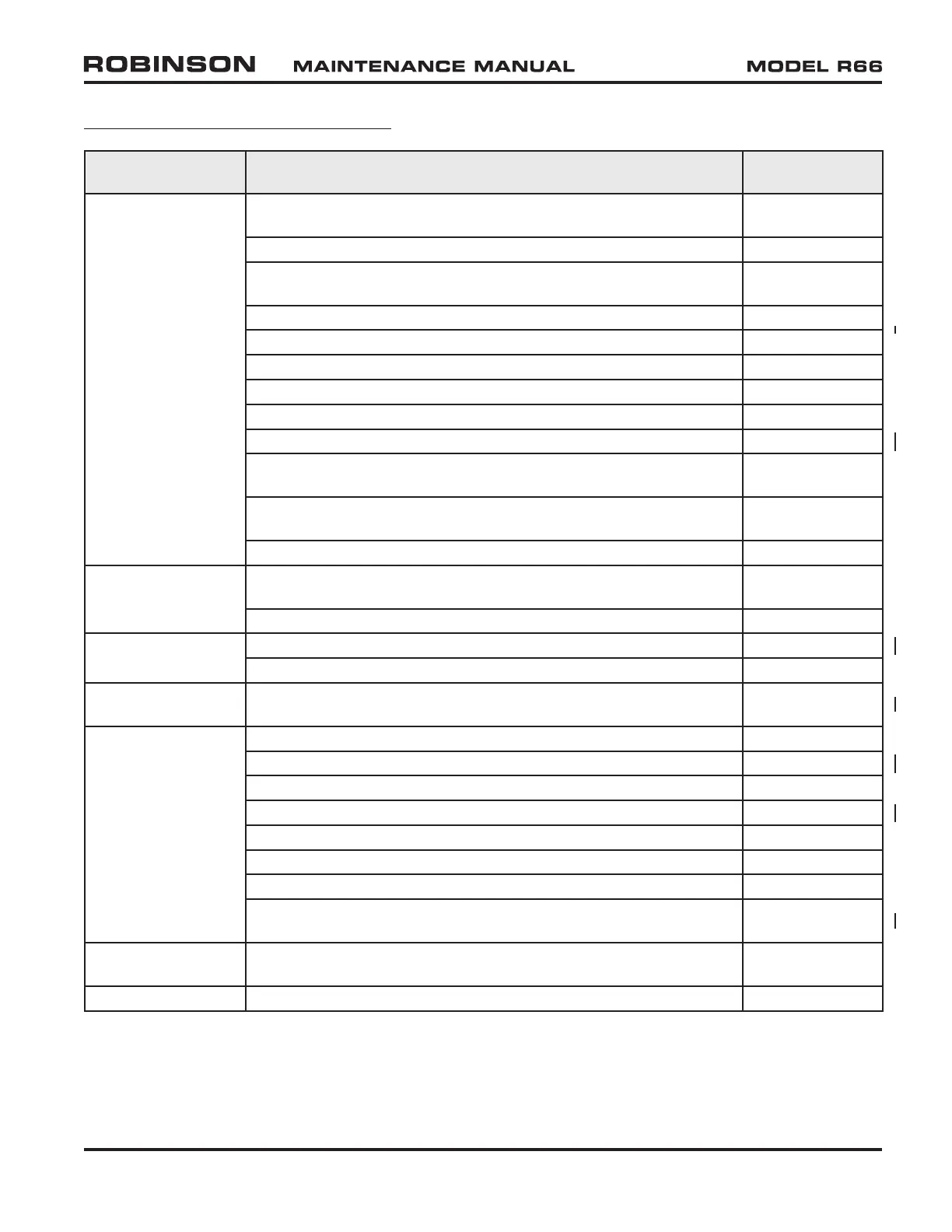

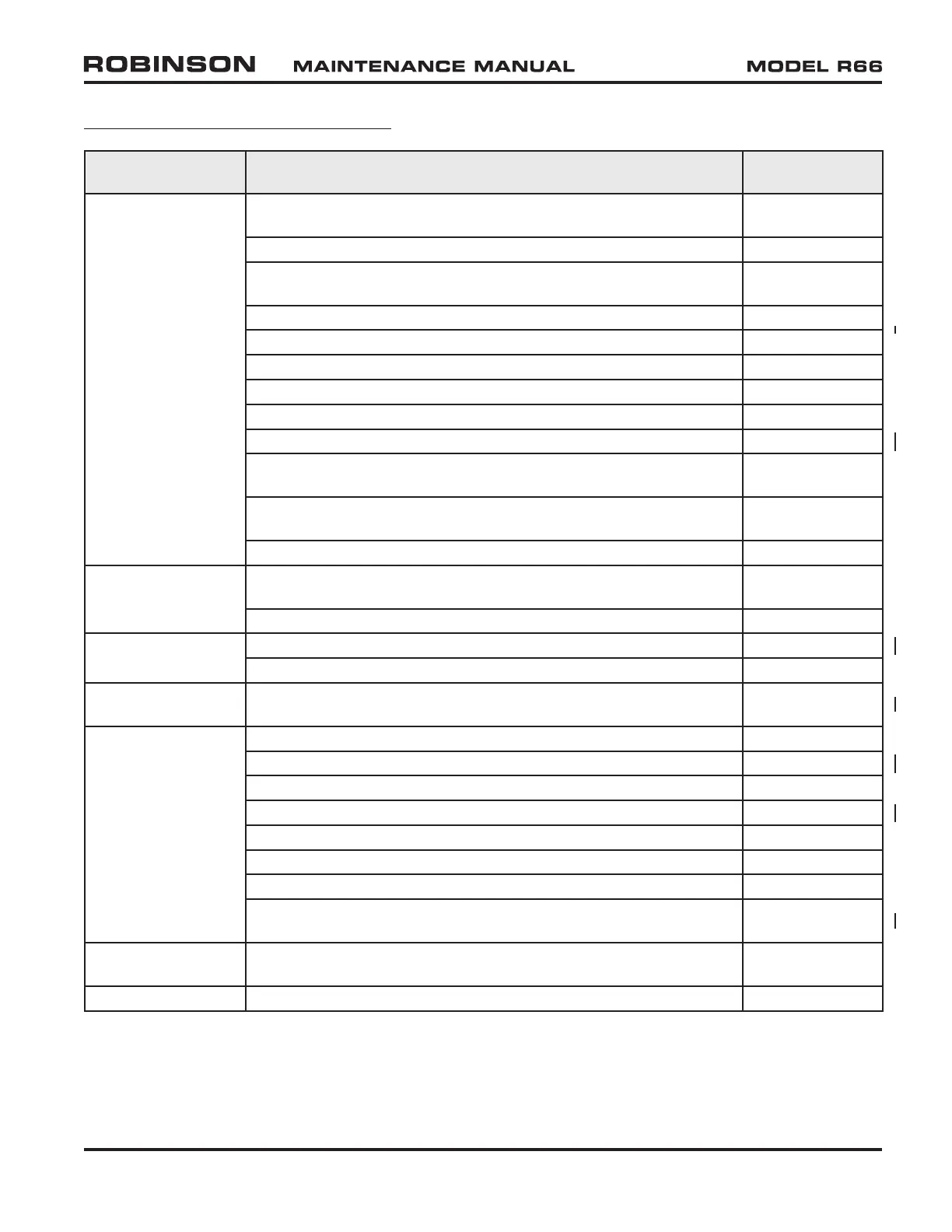

20-33 Special Torques (continued)

AREA* FASTENER*

TORQUE

(IN.-LB)*

POWERPLANT

(CONT'D)

(2) nuts, securing harness wires to starter-generator large terminals,

starter-generator supplied

180

(1) nut, securing harness wire to ignition exciter box, engine-supplied 15

(2) nuts, securing harness and (2) MS21919WCH4 clamps to engine

accesory gearbox, engine-supplied

40

(4) nuts, securing F577-1 bracket assembly, engine-supplied 40

(2) tee bolts, securing F173-1 struts to engine, engine-supplied 35-40

(2) AN815-8D unions, engine oil outlet and oil tank vent 250

(1) AN815-10D union, engine oil inlet 375

(1) AN919-0D reducer and (1) AN919-2D reducer 100

(2) NAS6605-3 bolt, securing G200-1 lug to engine (optional) 110

(6) NAS6605H3 bolts, securing (2) F593-1 support assemblies to

engine

110

(2) NAS6605H4 bolts and (1) NAS6605H2 bolt, securing F593-3

plate to engine

110

(1) CV26-77 check valve, engine oil outlet (early R66s) 250

SWASHPLATE

(26) NAS1352N08-8 screws, securing spacers, sleeve assembly,

shield, and retainers

35 wet

(2) NAS1352N08-4 screws, securing B769-2 bracket 35

TAIL ROTOR

(1) D210-4 nut, securing C119-2 bumper 120

(1) NAS6606-53 bolt, teeter hinge 380

TAIL ROTOR

FLIGHT CONTROLS

(1) D210-4 nut, outboard of F316-1 bellcrank assembly 90

TAIL ROTOR

GEARBOX

(1) A610-1 vent assembly 100

(1) B563-4 sight gage 150

(1) B566-2 chip detector 100

(1) D210-5 nut, pitch control housing 240

(1) AN320-8 nut, input yoke 35-45 FT-LB

(4) MS20074-04-06 bolts, input cap 60

(8) MS20074-04-06 bolts, input housing and output cap 100

(4) NAS1352-5-12P bolts (undrilled), gearbox-to-tailcone

attachment

260

TAIL ROTOR

GUARD

(1) NAS1352-3-14P screw, securing block assembly to stabilizer 40

WINDOWS (22) AN526C832R12 screw, thru center brace 16

* 1. Values include nut self-locking torque.

2. Increase values 10% if torqued at bolt head.

3. For elbow & tee fittings which require alignment, torque to indicated value then tighten to desired position.

4. Values ± 10% unless range is specified.

5. Unless otherwise noted, thread sizes 8-32 & smaller are not used for primary structure & do not require

specific torque.

MAY 2015 Chapter 20 Standard Practices Page 20.11

Loading...

Loading...