22-60 Maintenance

22-61 Scheduled Maintenance and Inspections

A. Ground Checks

NOTE

Perform the following ground checks after component replacement

or other repairs have been performed on the autopilot system.

Perform ground checks after an accident or incident that may have

affected autopilot or related equipment prior to return to service.

NOTE

Refer to § 22-62 for troubleshooting if any of the following ground

checks cannot be verified.

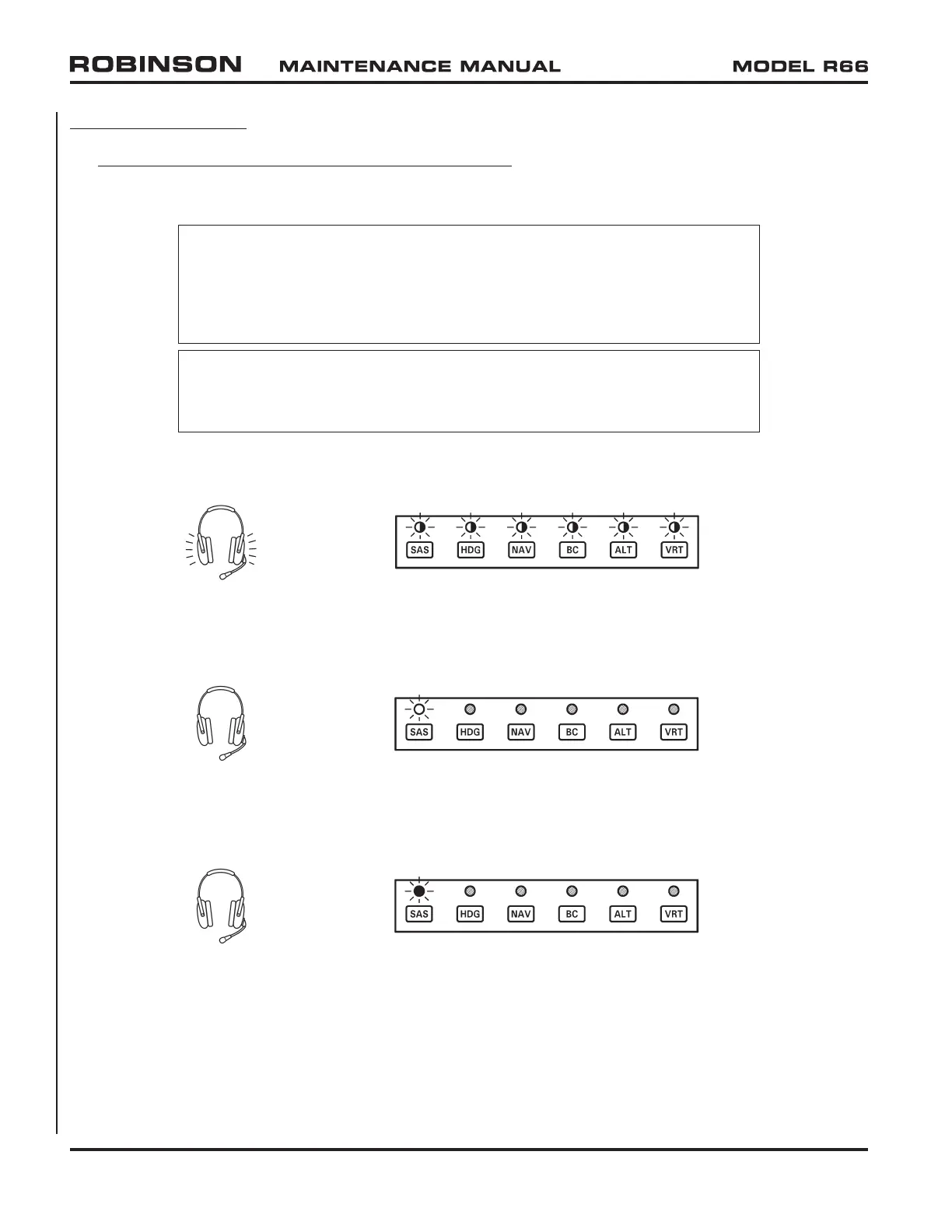

1. Turn battery & avionics switches on. Verify four beeps in headset and control

panel LEDS alternate white/green:

FOUR BEEPS

IN HEADSET

LEDs ALTERNATE

WHITE/GREEN

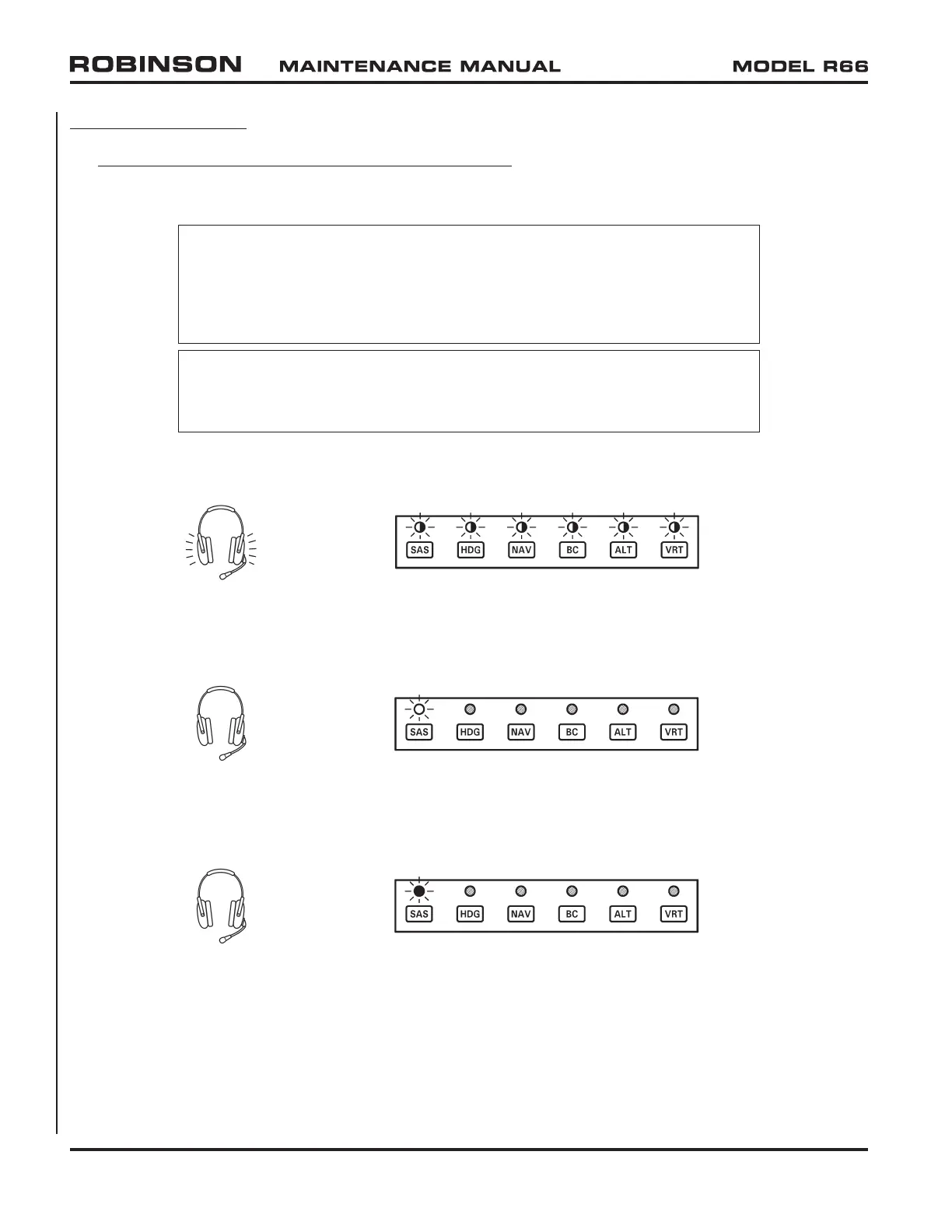

2. Verify SAS enters standby mode approximately 6 seconds after attitude indicator

caging flag exits window (pull and release caging knob if instrument bank angle

exceeds 6 degrees). Verify no sound in headset and control panel SAS LED is

white, other LEDs are dark:

NO SOUND

SAS LED IS WHITE,

OTHER LEDs DARK

3. Visually verify servo assembly arms do not move when moving cyclic.

4. Engage SAS mode (cyclic should feel "energized). Verify no sound in headset and

control panel SAS LED is green, other LEDs are dark:

NO SOUND

SAS LED IS GREEN,

OTHER LEDS DARK

5. Install & activate hydraulic test pump (to simulate hydraulics-on operation) per § 12-34.

a. With SAS engaged, displace cyclic at least 1 inch from neutral position and

verify SAS returns cyclic to neutral within ± 0.25 inch. Perform check for roll

& pitch axes.

b. With SAS engaged, displace cyclic full deflection, and verify 2.5–3.5 lb force

when displaced more than 1 inch from neutral position. Perform check for roll &

pitch axes.

Page 22.8 Chapter 22 Autopilot MAY 2015

Loading...

Loading...