5-34 Elastomeric Bearings

Refer to Figure 5-3. Elastomeric bearings are used in the G062-1 tail rotor hub. Fatigue,

oil contamination, or overload can degrade the elastomer.

Small surface cracks (fatigue cracks) and elastomer dust or “eraser crumbs” are normal and

are not cause for replacement. As cracks grow, enough elastomer will be lost to cause

reduced stiffness and increased vibration. Replace bearing if crack is deeper than 0.10 inch

or cracks are present over more than 25% of elastomer face.

Avoid elastomer exposure to oil, grease, hydraulic fluid, cleaning solvent, and rust-

preventative fluids. Immediately wash off contaminants with detergent and water. Replace

a contaminated bearing that exhibits swelling, wavy edges, or debonding.

Overload occurs when elastomer’s tensile strength or rubber-to-metal bond strength

is exceeded. This can occur when normal loads are applied to a bearing weakened by

fatigue or oil contamination. Overload is indicated by large clean cracks or extrusions from

elastomer.

Elastomer may also separate (debond) from metal bushings. Replace bearing if separation

exceeds 25% of bonded area.

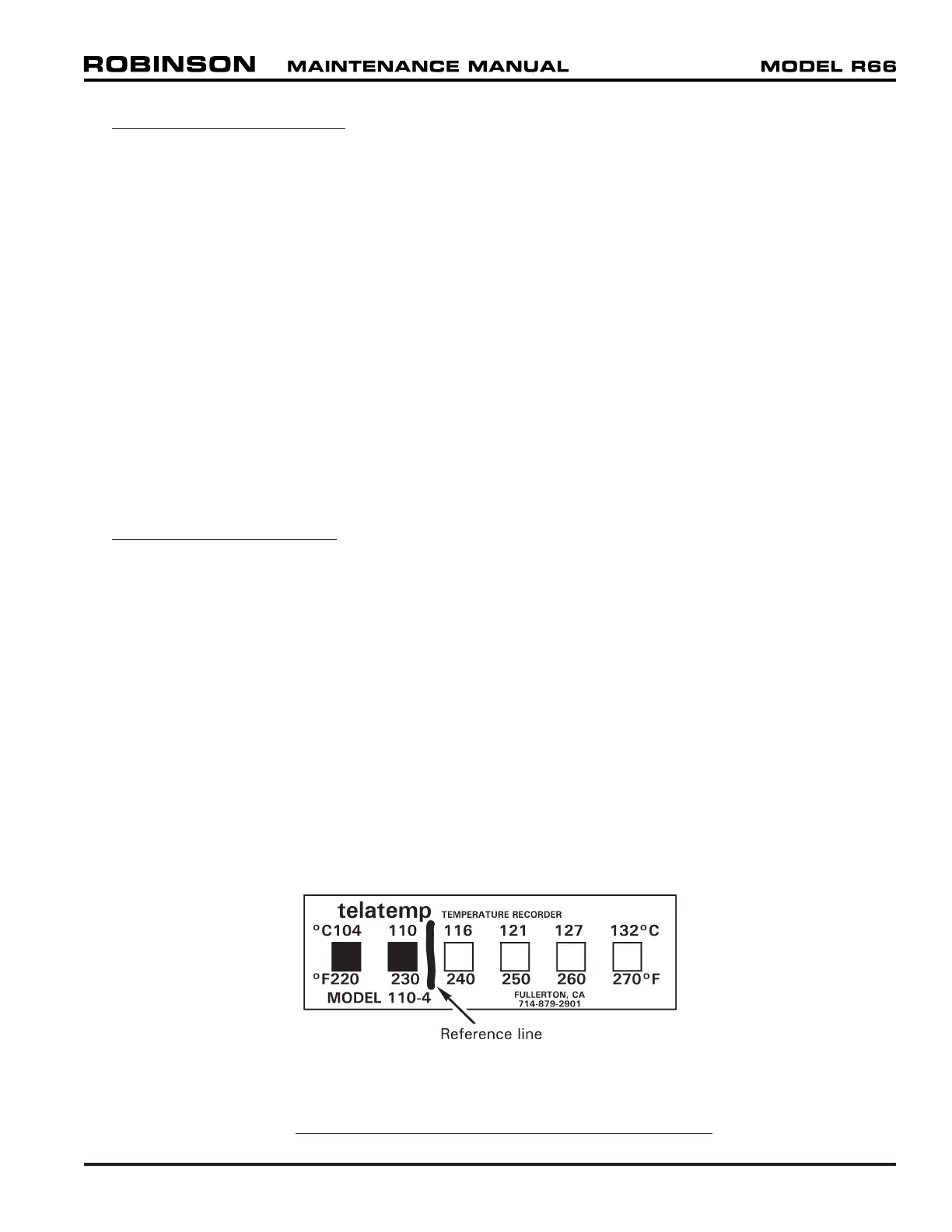

5-35 Telatemp Indicators

Refer to Figure 5-4. Self-adhesive Telatemp indicators record increases in operating

temperatures of the hydraulic pump and tail rotor gearbox. To use a Telatemp, draw a

reference line between the highest temperature square which has darkened during normal

operation and the next undarkened square. During every check thereafter, determine if an

additional block has blackened. If an indicated temperature increase cannot be accounted

for by a change in operating conditions, subject component should be carefully examined

before further flight.

Part Number Temperature Range

110-2 60°C / 140°F — 88°C / 190°F

110-3 82°C / 180°F — 110°C / 230°F

110-4 104°C / 220°F — 132°C / 270°F

FIGURE 5-4 TELATEMP WITH DRAWN REFERENCE LINE

SEP 2012 R66 Maintenance Manual Chapter 5 Inspection Schedule Page 5.7

Loading...

Loading...