32-61 Cylinder Assembly (continued)

C. Filling

CAUTION

Use appropriate eye and hearing protection. Do not service

cylinder assembly while cylinder is installed in helicopter.

WARNING

ONLY cylinders labeled “DOT-E 10915-4945” may be refilled.

Cylinders labeled “DOT-E 10915-4500” must be returned to

RHC for exchange/upgrade.

WARNING

Verify D757-1 (gray) valve assembly is engraved with “D758-4”

or has a data plate indicating B900-8 modification.

Filling equipment (pumps, hoses, fittings, etc.) must be rated for 6000 psi minimum

working pressure and be in good condition.

Cylinder temperature and pressure must be kept within safe limits. Monitor pressure gage

and use thermocouple or other appropriate temperature probe to monitor temperature

on face of thermal relief fitting during fill. Do not allow temperature to exceed 50ºC

(122ºF) or pressure to exceed 5500 psig. If limits are approached, stop fill and allow

cylinder to cool and pressure to drop before continuing. Placing cylinder in a water bath

and using slow to moderate fill rates is recommended. If using water bath, keep water

level below valve assembly to avoid water contamination of valve.

1. Evaluate cylinder life and hydrostatic test status.

2. Refer to Figure 32-5. Install MT545-1 pin assembly in D757-1 valve assembly.

Install MT546-1 diffuser on valve fitting and special torque diffuser to 120 in.-lb.

3. Remove D760-7 cap (etched with “FILL PORT”) from valve assembly. A loud pop

may be heard when cap’s seal is broken.

4. Install MT546-2 adapter assembly into fill port and special torque adapter to 40 in.-

lb. Attach fill hose to adapter.

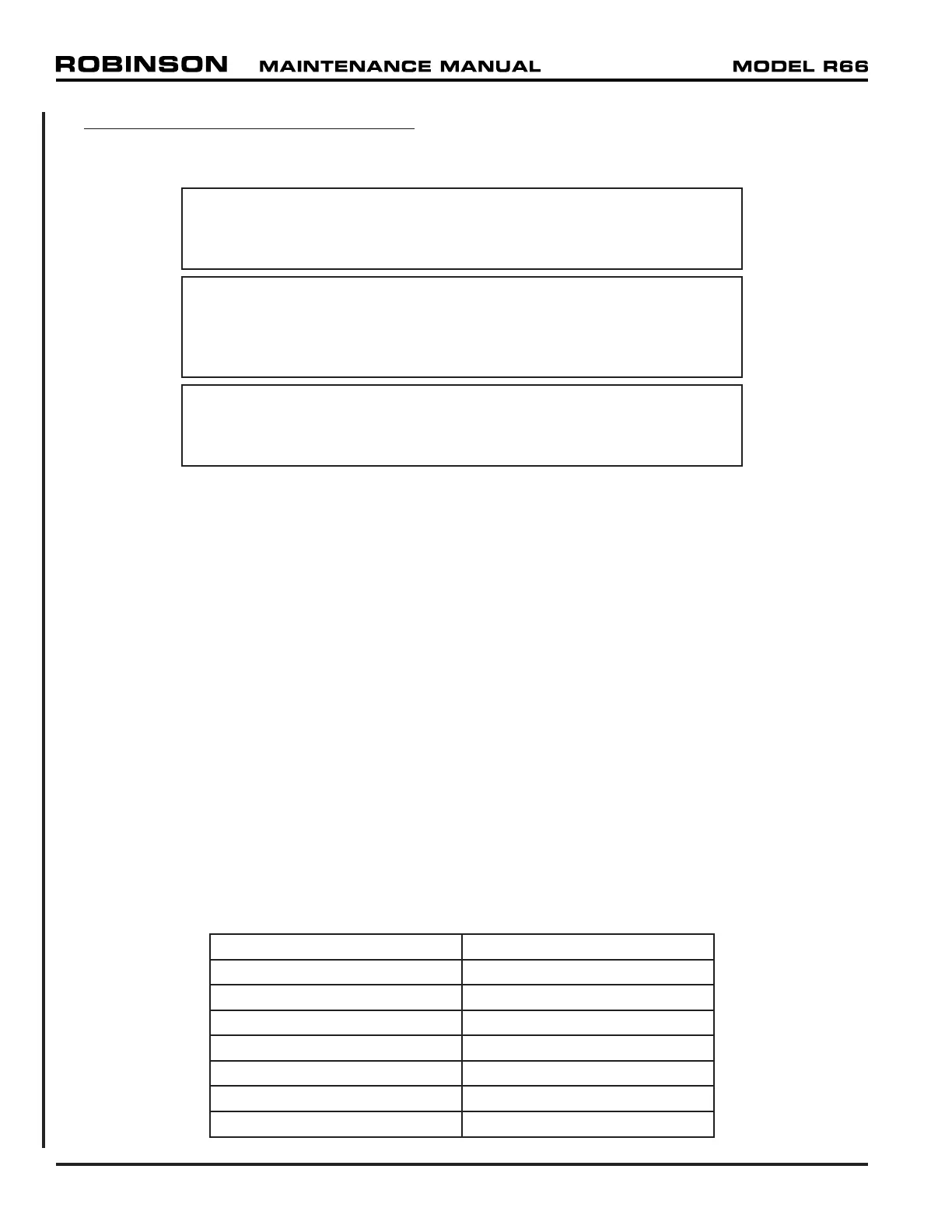

5. Fill with 99.98% minimum purity (industrial grade) helium per chart below:

Ambient Temperature (ºC) Pressure (psig)

-20 4268

-10 4437

0 4606

10 4776

20 4945

30 5114

40 5283

Page 32.14 Chapter 32 Landing Gear R66 Maintenance Manual SEP 2012

Loading...

Loading...