*

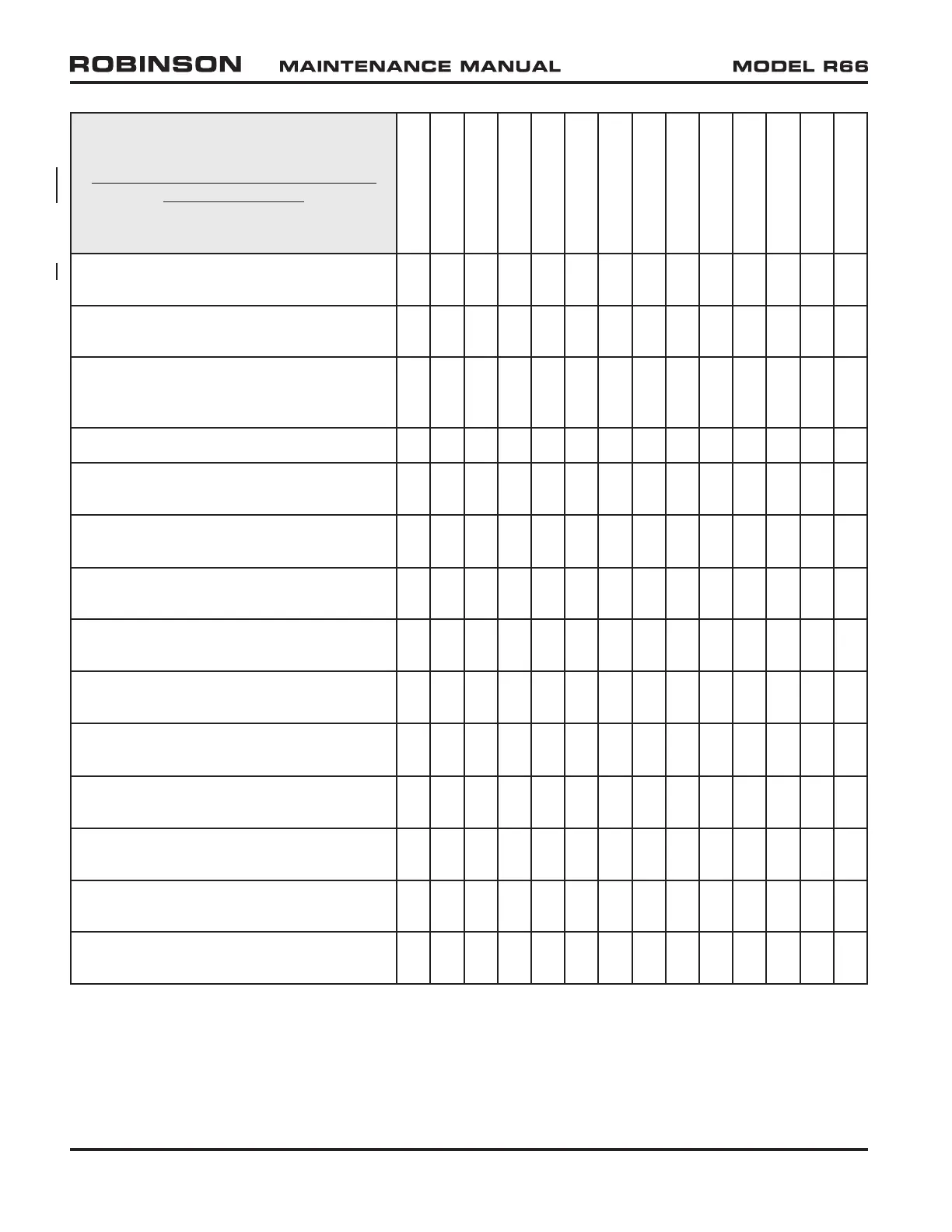

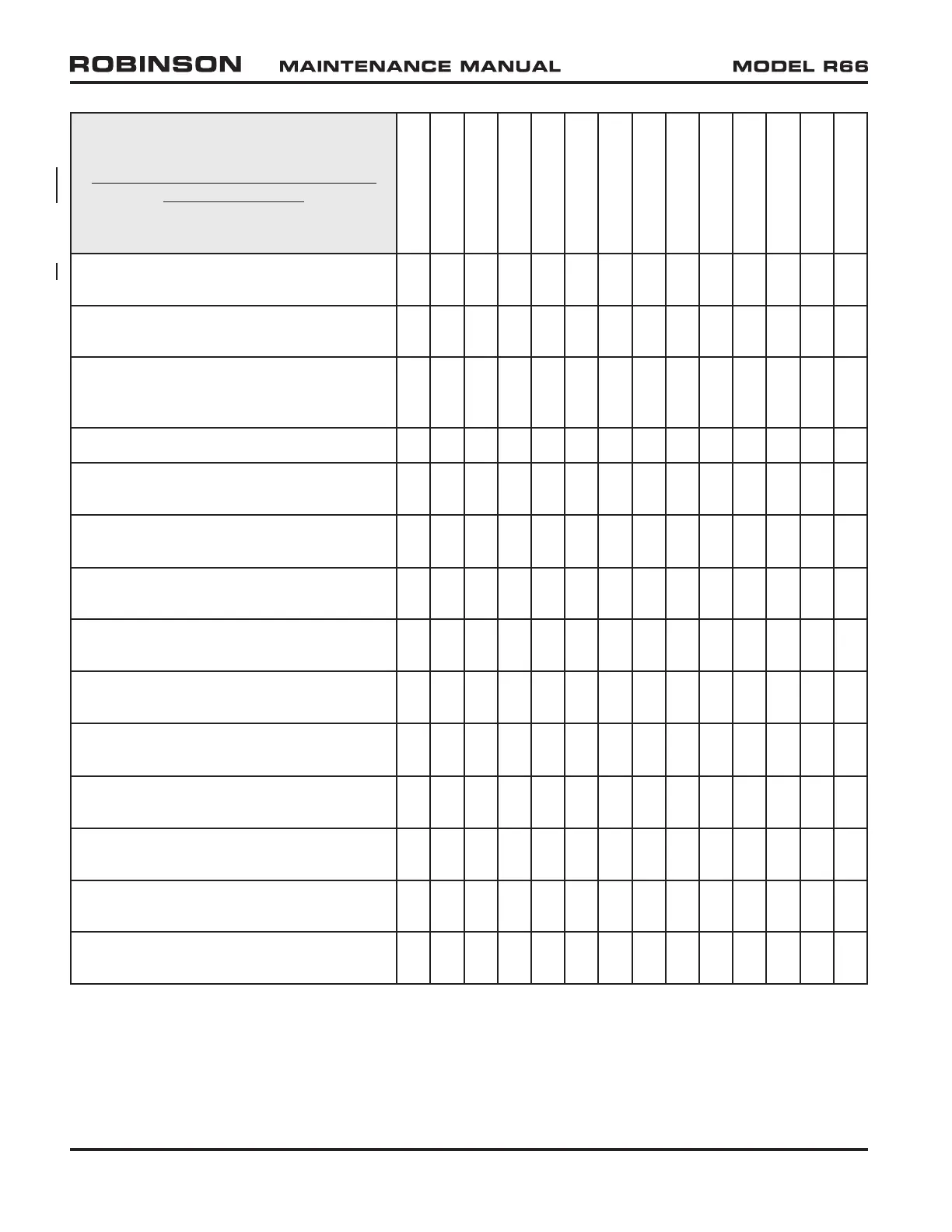

One-time maintenance after new or overhauled main rotor gearbox is installed.

**

Recurring inspection not to exceed given interval.

***

See § 1-60 Definitions and Abbreviations.

Page 5.2 Chapter 5 Inspections MAY 2015

Replace main rotor gearbox oil and filter

per § 12-12.

• •

Perform 100-hour / annual maintenance

and inspection per § 5-45.

• •

As required by RR300 Series Operation

and Maintenance Manual (OMM), perform

maintenance and inspection.

• • • • •

Replace hydraulic filter per § 12-32.

•

Drain and flush tail rotor gearbox per §

12-23.

•

Clean gearbox chip detectors per § 12-13

& 12-22.

• •

Perform 2000-hour maintenance and

inspection per § 5-50.

•

Inspect emergency locator transmitter

(ELT) per 14 CFR § 91.207.

•

Perform pop-out float leak check per § 32-

64 Part A.

•

Test and inspect transponder per 14 CFR §

91.413.

•

Perform pop-out float inflation check per §

32-64 Part B.

•

Peform pop-out float pressure cylinder

hydrostatic test.

•

Perform 12-year maintenance and

inspection per § 5-55.

•

Pop-out float pressure cylinder maximum

life.

•

First 100 Hours*

100 Hours**

200 Hours**

400 Hours**

600 Hours**

2000 Hours**

Annually***

12 Months**

24 Months**

3 Years**

5 Years**

12 Years**

15 Years**

3000 Cycles**

TABLE 1 SCHEDULED MAINTENANCE

AND INSPECTIONS

Loading...

Loading...