5. INFORMATION ON ADJUSTMENTS

5.1. RECOMMENDATIONS FOR ADJUSTMENTS

- Before performing any operation, the authorised operator must make sure to have understood the “Instructions

for use”.

- Activate all the safety devices provided, stop the machine and assess whether there is any residual energy

before carrying out the operations.

- Provide suitable safety conditions in compliance with the regulations on workplace safety to prevent and

minimise the risks.

- Pay attention to the safety warnings, do not misuse the machine and assess the possible residual risks.

5.2. INFEED AND OUTFEED CONVEYOR HEIGHT ADJUSTMENTS

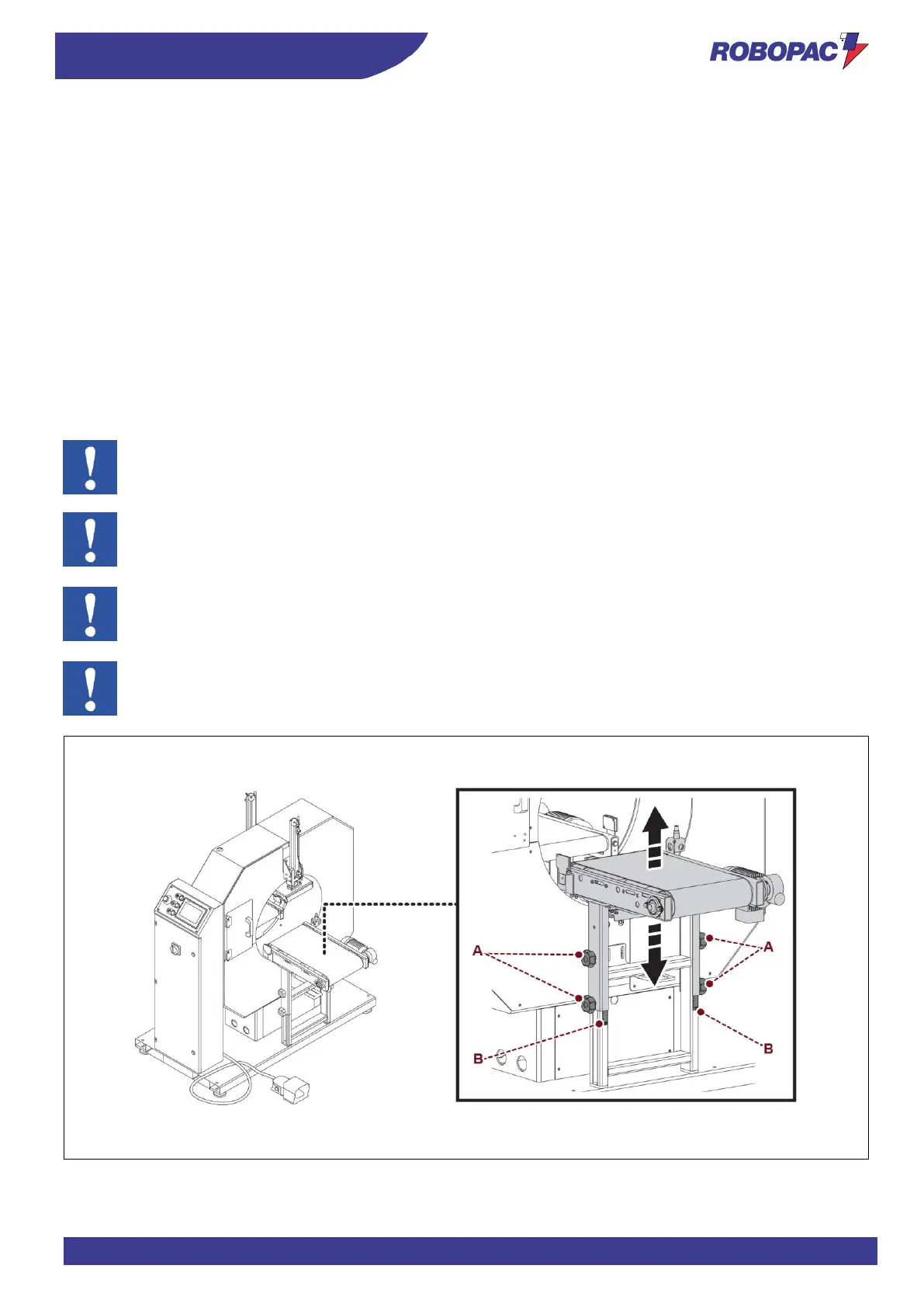

Adjustments of conveyor height (Compacta S4-S6-S9)

According to the product to be wrapped, adjust the infeed and outfeed conveyor height.

1. Loosen knobs (A).

2. Position the conveyors checking the height on the graduated scale (B).

3. Tighten knobs (A).

Important

If the optional gas spring is installed under each conveyor, keep in mind that: once the knobs have been

loosened, the conveyor tends to move upwards by itself.

Important

Conveyors must be coplanar to each other; however, only in particular cases, the outfeed conveyor can

be few millimetres below the infeed one.

Important

When processing very wide products you must lift the conveyors up to their maximum height from the

ground within the product height limits (

see section 3.6. “Technical specifications”

).

Loading...

Loading...