AX10 Palletizing Solution

1.1.2. Linear Axis

To extend the reach of the robot, a linear axis is installed inside the column. It allows the robot to move vertically in order to build

high pallets.

1.1.3. Linear Axis Controller

All the components of the Solution are integrated and controlled via the linear axis controller. It allows for the simultaneous

motion of both the axis and the robot during a palletizing process, and the control of the pallet sensors and status lights.

1.1.4. Pallet Sensors

The Solution is composed of four (4) sensors used to detect pallet presence (two per pallet). The sensors will allow the Solution to

ensure that the pallets are well positioned on each side of the base to optimize the application process.

1.1.5. Status Lights

Two (2) status lights are positioned at the top of the base. Each status light is associated with the nearest pallet. The color of the

light gives information on the status of the system or the state of a specific pallet. Please refer to the Status Light States section for

more information.

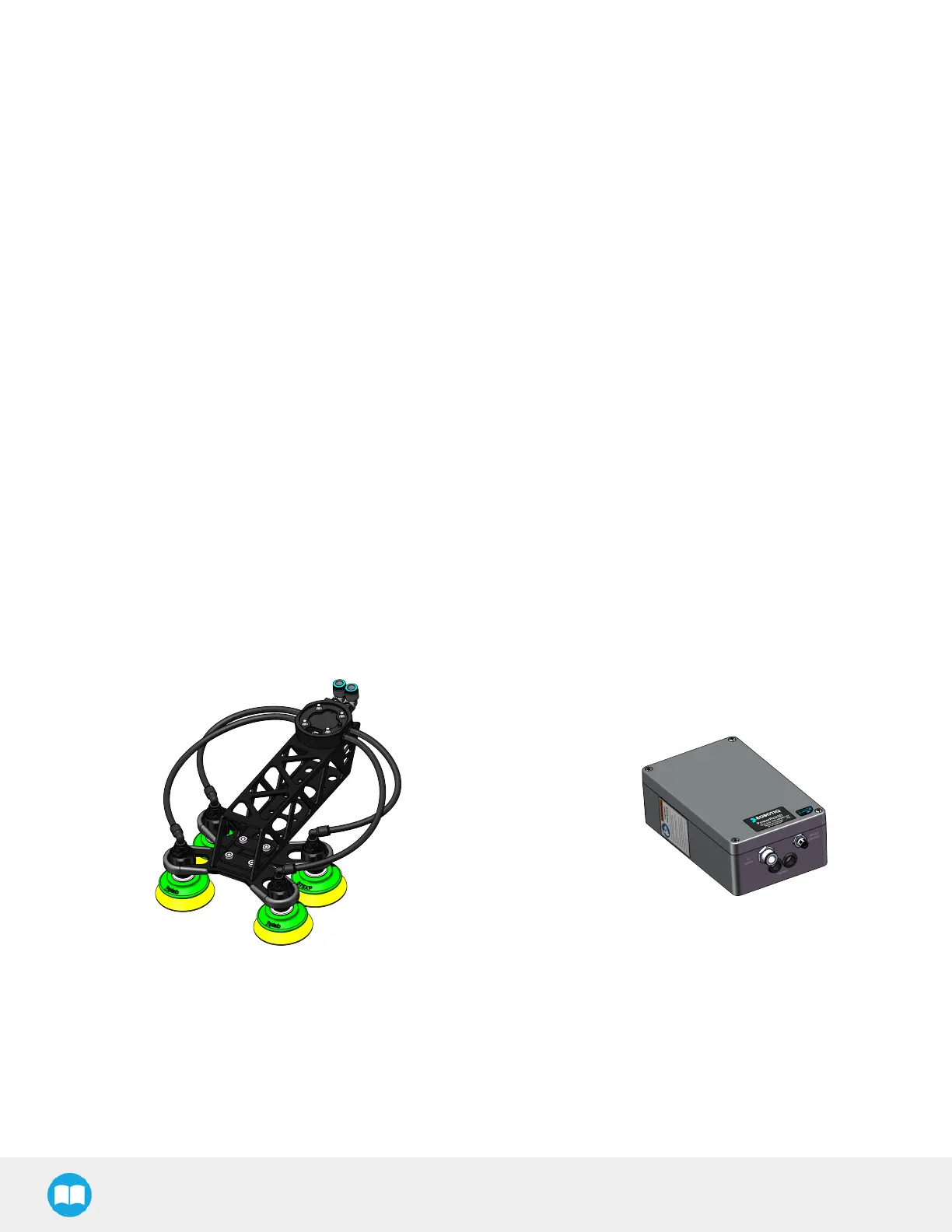

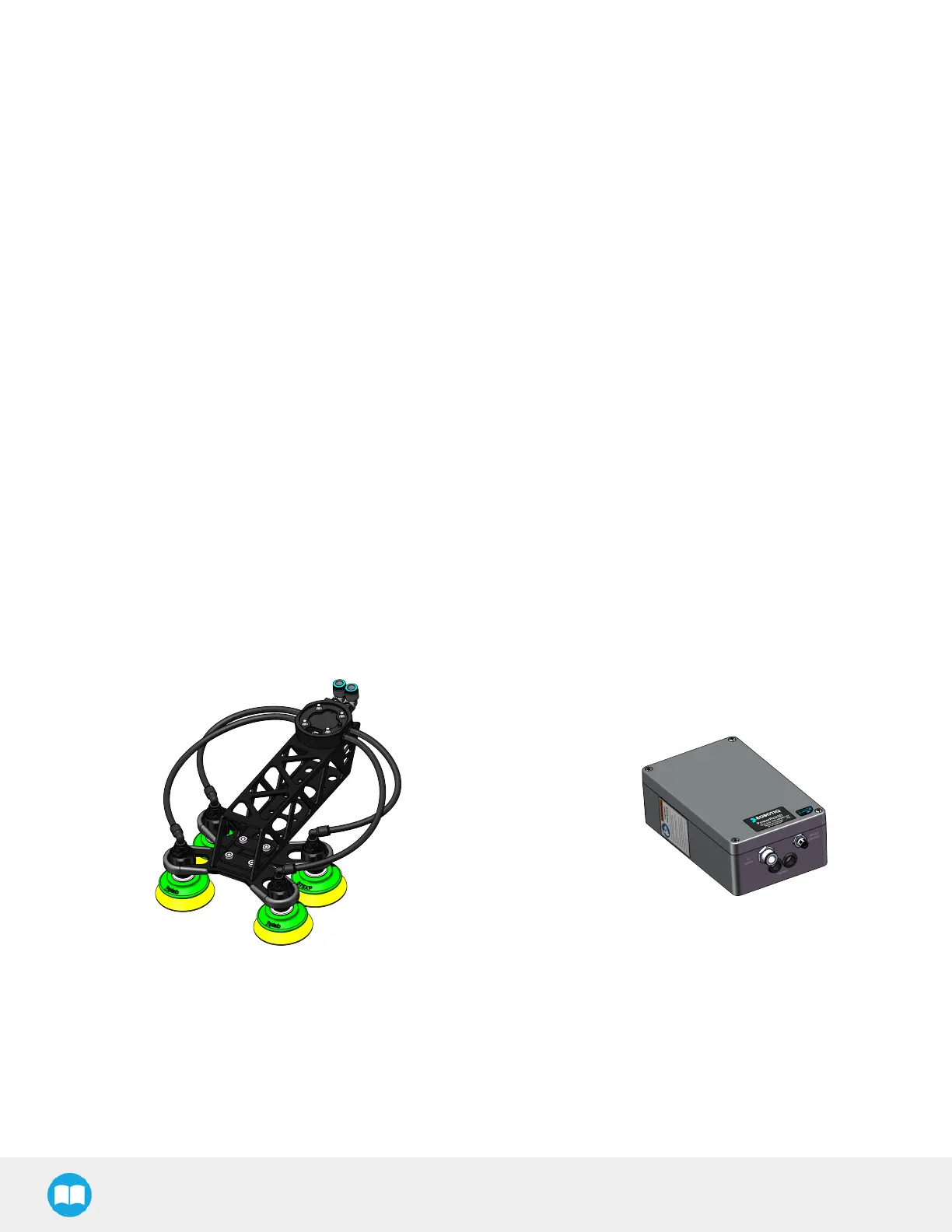

1.1.6. PowerPick10 Vacuum Gripper (Optional)

PowerPick10 is a vacuum gripper that uses a venturi system to generate vacuum from a compressed air energy source. The

PowerPick10 interfaces with the robot via input/output (I/O) cables connected directly to the robot controller.

The kit consists of a gripper, multiple suction cups and interchangeable components, along with a dual-channel vacuum

generation unit. The unit also includes a shut-off valve and an integrated filter regulator.

Its design is suitable for the Robotiq Palletizing Solution when used with a UR10e robot (weight, payload, independently

controllable channels).

Fig. 1-2: PowerPick10 Gripper and Vacuum Generator

Interchangeable Components

The PowerPick10 Gripper can be installed with various interchangeable components including suction cup brackets, an offset

plate, hollow offset links, a tubular wrist extension and various suction cups depending on the application, object material and

grasping requirements.

10

Loading...

Loading...