AX10 Palletizing Solution

10. Troubleshooting

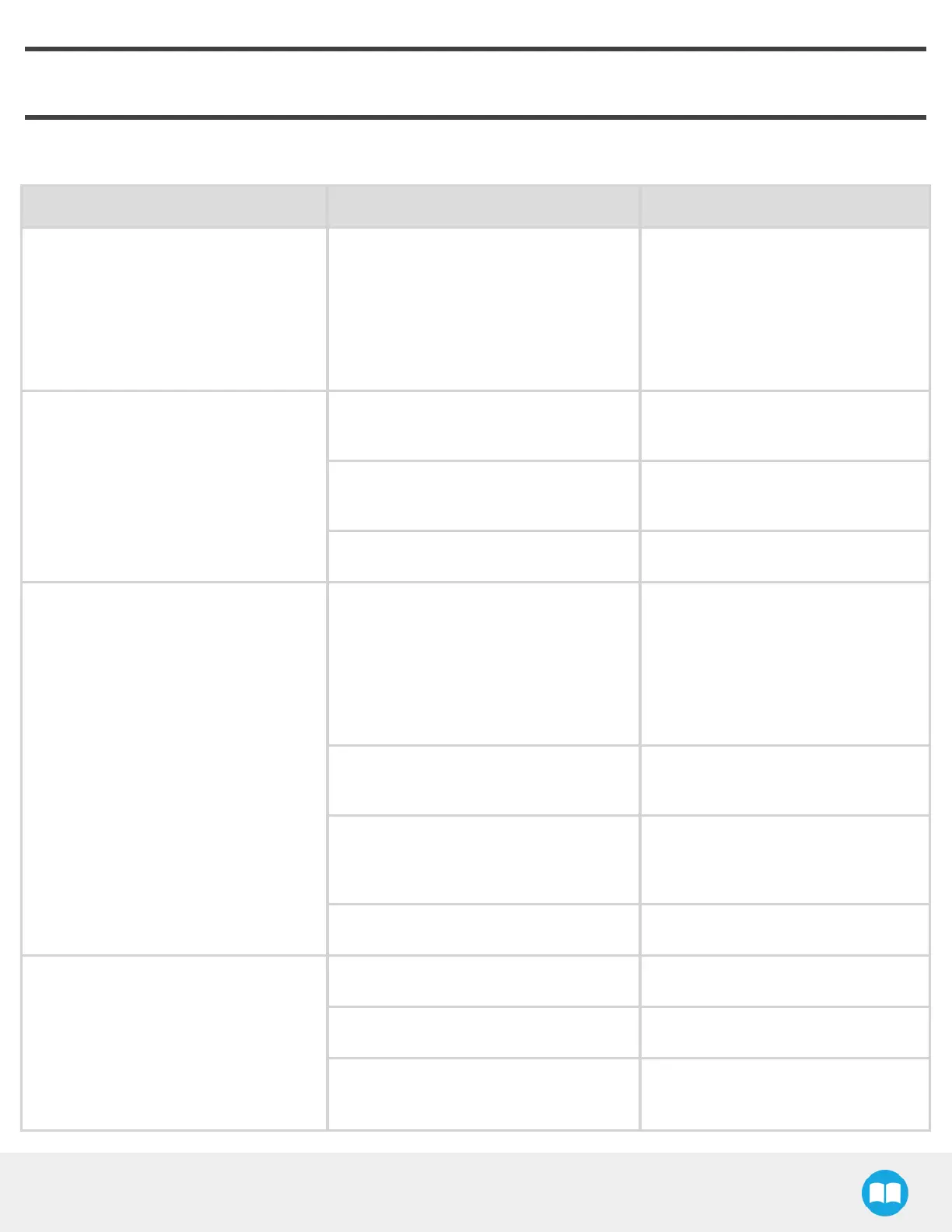

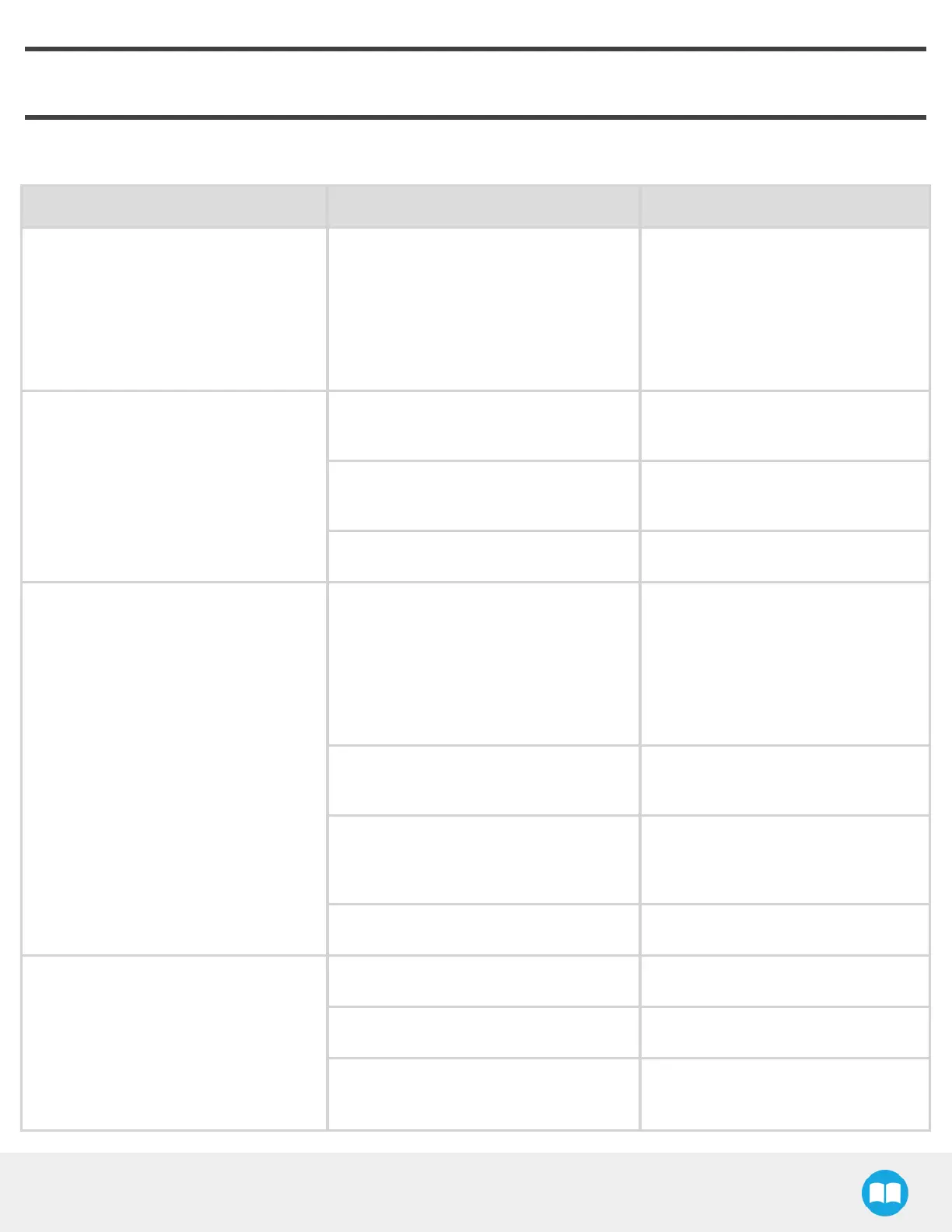

10.1. Palletizing Solution (excluding the PowerPick10 Vacuum Gripper)

Symptom / Issue Cause Solution

Robot comes to a protective stop after

palletizing a few layers

A collision occurred between the

gripped box and a box on the pallet.

A minor palletizing error carried over

from previous layers.

Increase box height value to

compensate for box size

discrepancies. A good practice to

determine box height is to measure

the height of a full pallet (boxes only),

and divide it by the number of layers

on the pallet.

Robot drops boxes from great heights

Minor palletizing error carried over from

previous layers.

Decrease the box height value.

Incorrect TCP.

Confirm TCP is located above the

box, at the picking position.

Pallet height value is too low. Increase pallet height value.

Robot collides with palletized box

A collision occurred between the

gripped box and a box on the pallet.

A minor palletizing error carried over

from previous layers.

Increase the box height value to

compensate for box size

discrepancies. A good practice to

determine box height is to measure

the height of a full pallet (boxes only),

and divide it by the number of layers

on the pallet.

One or several faces of the box are

rounded.

Increase box width and/or box length

value.

Pallet viewer does display actual pallet

state.

Inspect Pallet viewer at program start

and confirm the virtual layout

matches the actual layout.

Pallet height value is too high. Decrease the pallet height value.

Protective stop triggered by robot

placing a box on first layer

Box height value is too high. Verify the box height value.

Pallet height value is too high. Verify the pallet height value.

Incorrect TCP.

Confirm that the TCP has been set

correctly.

Loading...

Loading...