AX10 Palletizing Solution

Ball Screw and Bearing Guide Lubrication

Lubrication of the axis should be performed every two (2) years considering a typical use of 80h/week. When lubricating, move the

carriage along the entire axis rail to distribute the lubricant evenly.

Cover Strip and Guide Rail Lubrication

Lubrication has to be performed when and if it is needed or when the component has lost its grease film.

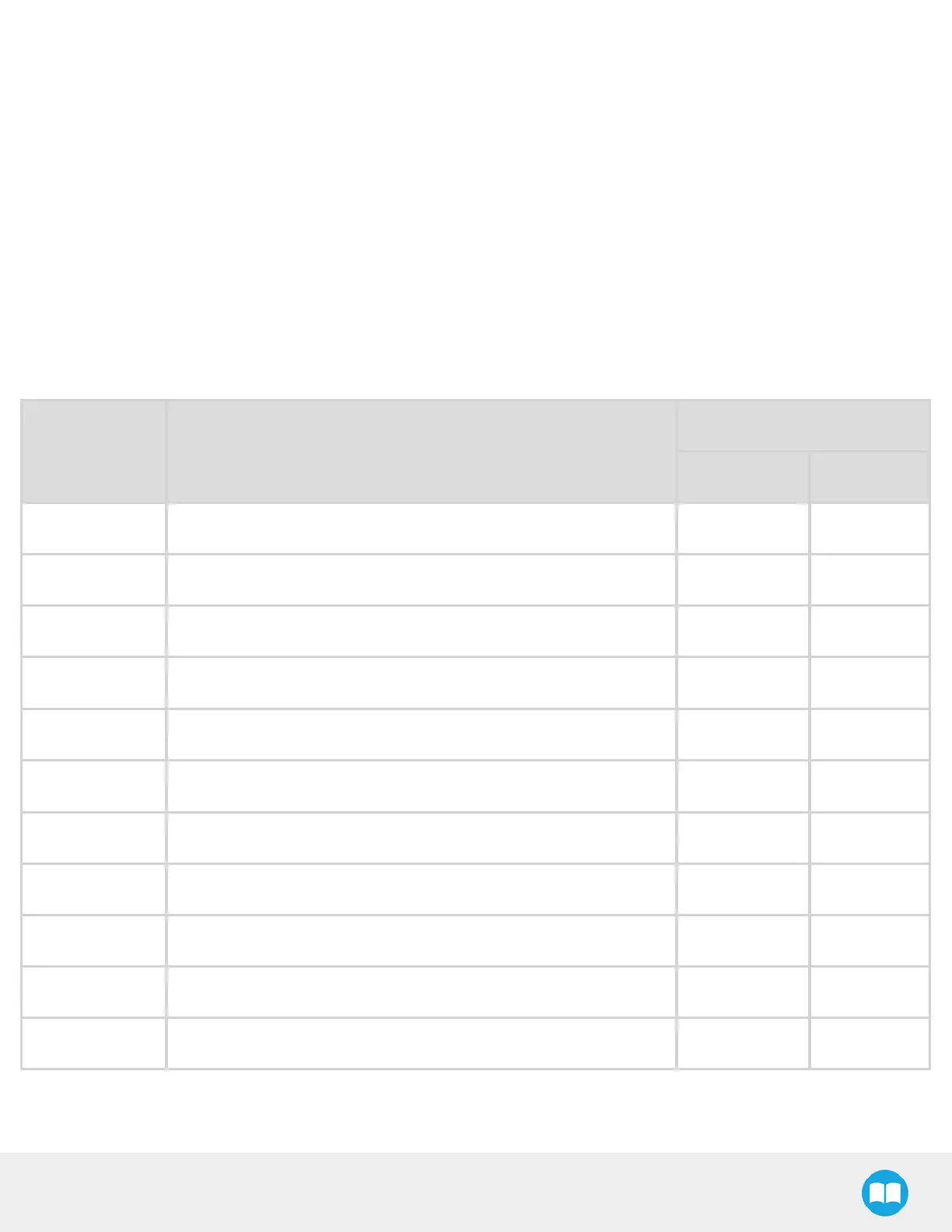

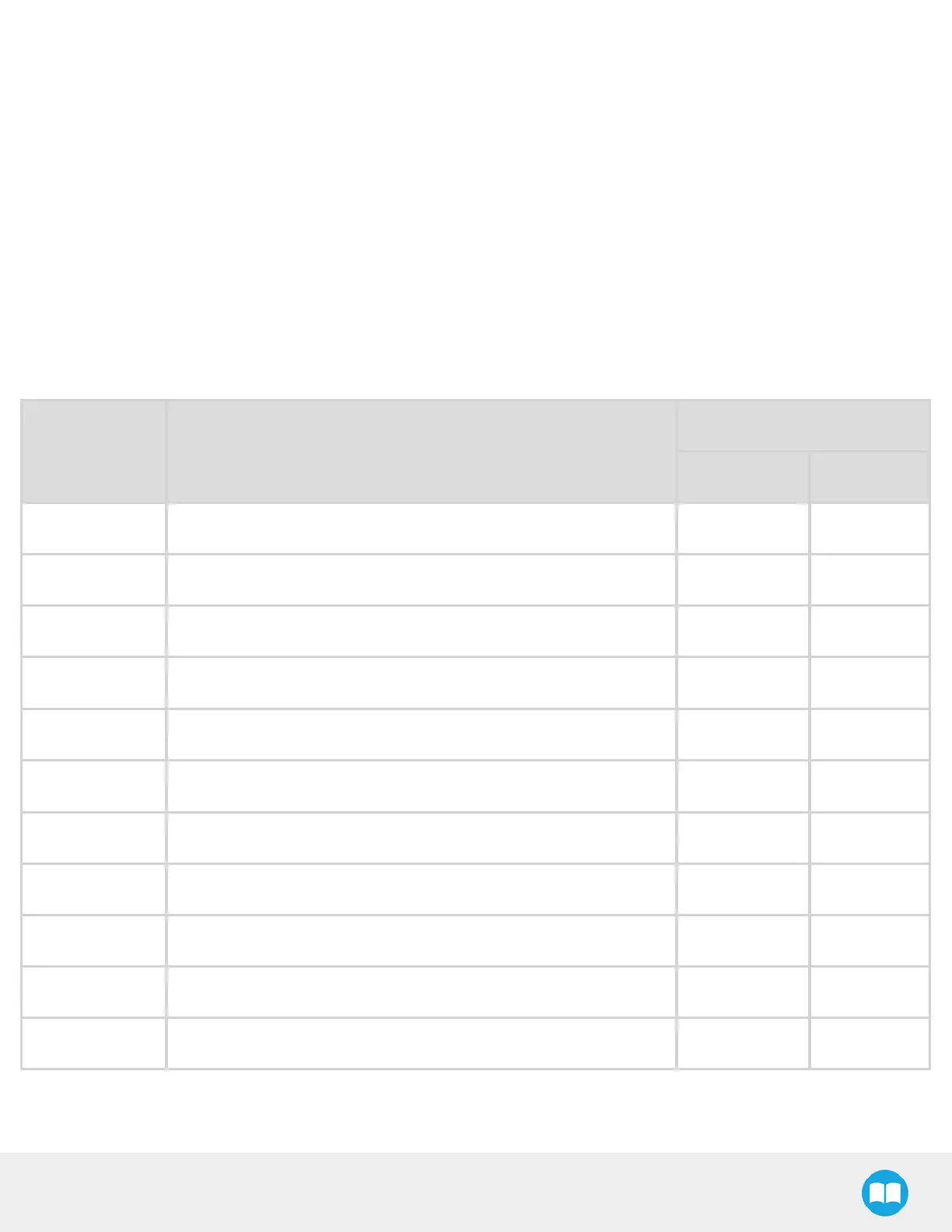

8.3. Fastener Specifications

Inspect all screws and bolts periodically to make sure they are tightened to the appropriate torque, as represented in the table

below.

Diameter / TPI Location

Torque

[Nm] [lb-ft]

M6 Column-Axis interface 10.5 7.7

M6 Linear axis carriage interface 9.9 7.3

M8 Pallet sensors 15.0 11.1

M8 Linear axis controller 15.0

11.1

M10 Base - Column 50.0 36.9

1/2"-13 Wedge anchors 54.2 40.0

M8 Hoist ring 9.5 7.0

M8 Robot-carriage link 20.0 14.8

M8 Lifting bracket - Linear axis link 9.5 7.0

Motor Coupling Coupling collar 8.0 5.9

M8 Control box and Vacuum Generation Unit holder plates 5 3.7

Table 8-1: Torque Values - Palletizing Solution

Loading...

Loading...