22 Rockwell Automation Publication 440R-UM013G-EN-P - December 2022

Chapter 3 Power, Ground, and Wire

When changing the function from mechanical switches or OSSDs to safety mats, GSR safety

relays must go through the complete configuration process.

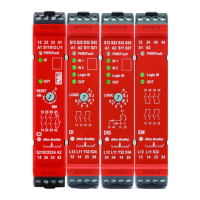

Figure 12

shows the typical connections for safety mats. You notice the reverse of the wiring

between a device with 2 N.C. contacts and the safety mat.

When a safety mat is used, safety relays cannot detect short circuits between the inputs or

between the inputs and 24V DC. Test these conditions during validation.

Figure 12 - Example One Connection to Safety Mats

Because the safety mats are parallel plates, they have a significant capacitive effect. The

larger the safety mat, the more capacitance. If the capacitance is too large, the safety relay

does not function properly. See Capacitance Effect

on page 61 for further information.

Figure 13 on page 23

shows an example where the safety mat and a device with pulse-testing

OSSD outputs are connected to the DI or DIS safety relay. In this example, performance is

independent of the input connection (IN1 or IN2). The devices must be connected and circuits

closed during the configuration process and upon normal power-up. Upon normal power-up,

the DI and DIS safety relay attempts to determine whether a safety mat is connected. During

the power-up test, the DI and DIS safety relay may detect the pulse test of the OSSD device at

the same time it is trying to determine if a safety mat is connected and determine that a

configuration is incorrect. If this situation occurs, another power-up cycle is required.

IMPORTANT For fault detection purposes, configure GSR safety relays for monitored

manual reset when connected to safety mats.

IMPORTANT When using safety mats, set the DI and DIS safety relays for AND logic. If

you use only one safety mat, connect the second input with jumpers or to

another safety device. If another safety device connects to the second

input, the outputs of the safety device must be on during configuration

and during power-up.

Allen-Bradley® Guardmaster MSR safety relays can be tickled by tapping on the

safety mat, which generated fast cycles. This activity caused the safety relay to

fault because the fast cycles violated the recovery time specification. GSR safety

relays have a faster recovery time (30 ms). However, there is a small window of

actuation times (around 20 ms) that can cause a GSR relay to enter a faulted state

(steady red PWR/Fault indicator); a power cycle is required to clear the fault.

When you combine mats with devices with OSSD outputs, the duration and period

of the OSSD pulses affects the potential of a power-up fault. OSSD outputs with

shorter pulse widths and longer periods contribute to fewer power-up faults.

S11 S21 S22 S12 S42 S32S11 S21 S22 S12 S11 S21 S22 S12 S42 S32

Mat 1

Input 1

Input 1 Input 2

Pulse

Testing

Outputs

Pulse

Testing

Outputs

CI and SI

DI and DIS

Input 1 Input 2

Pulse

Testing

Outputs

DI and DIS

Mat 1

Mat 2 Mat 1 EM Device

Loading...

Loading...