232 Rockwell Automation Publication 520-UM001K-EN-E - August 2021

Appendix F PID Set Up

Analog PID Reference

Signals

Parameters t091 [Anlg In 0-10V Lo] and t092 [Anlg In 0-10V Hi] are used to

scale or invert an analog PID Reference or PID Feedback.

Scale Function

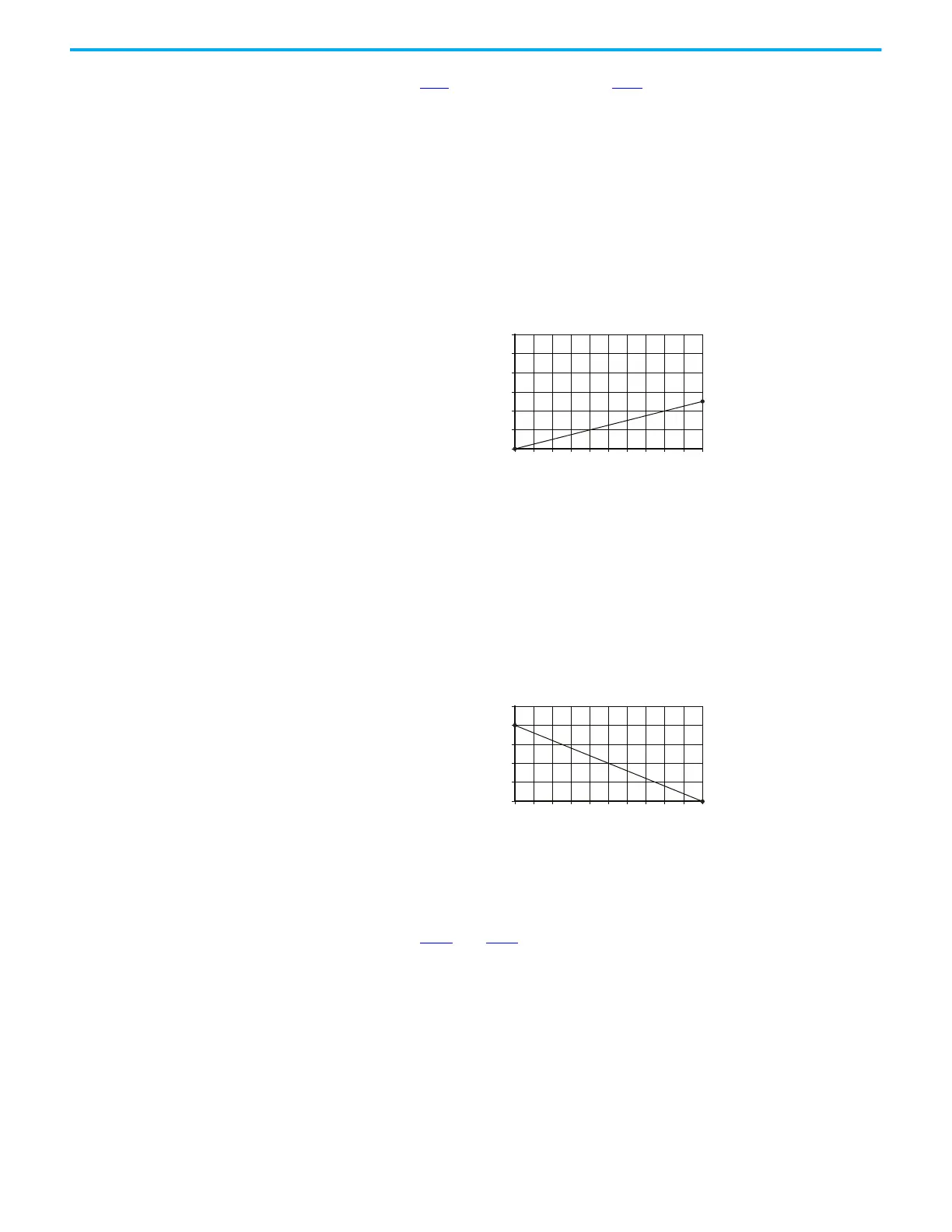

For a 0...5V signal, the following parameter settings are used so that a 0V

signal = 0% PID Reference and a 5V signal = 100% PID Reference.

• t091 [Anlg In 0-10V Lo] = 0.0%

• t092 [Anlg In 0-10V Hi] = 50.0%

• A459 [PID 1 Ref Sel] = 5 “0-10V Input”

Invert Function

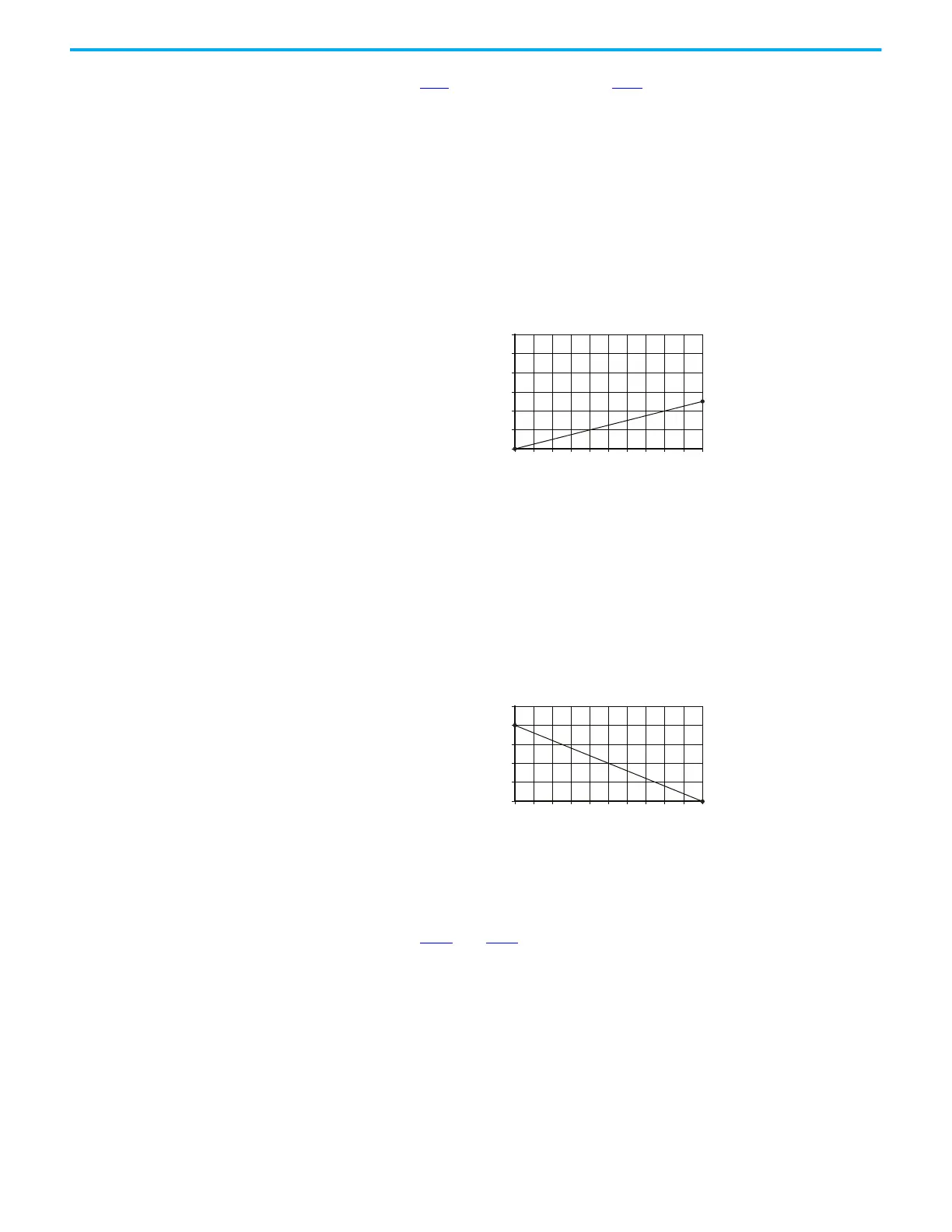

For a 4…20 mA signal, the following parameter settings are used so that a 20

mA signal = 0% PID Reference and a 4 mA signal = 100% PID Reference.

• t095 [Anlg In4-20mA Lo] = 100.0%

• t096 [Anlg In4-20mA Hi] = 0.0%

• A459 [PID 1 Ref Sel] = 6 “4-20mA Input”

PID Deadband

Parameters A465 and A477 [PID x Deadband] are used to set a range, in

percent, of the PID Reference that the drive will ignore.

Example

• A465 [PID 1 Deadband] = 5.0%

•The PID Reference is 25.0%

• The PID Regulator will not act on a PID Error that falls between 20.0 and

30.0%

0 10 20 30 40 50 60 70 80 90 100

PID Reference (%)

Input Volts

2

4

6

8

10

12

0102030405060708090100

PID Reference (%)

4-20 mA Input

4

8

12

16

20

24

Loading...

Loading...