234 Rockwell Automation Publication 520-UM001K-EN-E - August 2021

Appendix F PID Set Up

parameter is scaled so that when it is set to 1.00, the process response is

0.1% of P044

[Maximum Freq] when the process error is changing at 1% /

second. A larger value for [PID x Diff Rate] makes the differential term

have more of an effect and a small value makes it have less of an effect.

In many applications, the D gain is not needed. Setting [PID x Diff Rate]

to 0.00 (factory default) disables the differential component of the PID

loop.

Guidelines for Adjusting the PID Gains

1. Adjust the proportional gain. During this step it may be desirable to

disable the integral gain and differential gain by setting them to 0. After

a step change in the PID Feedback:

- If the response is too slow increase A461 or A473 [PID x Prop Gain].

- If the response is too quick and/or unstable (see Unstable Response

on

page 234), decrease A461 or A473 [PID x Prop Gain].

- Typically, A461 or A473 [PID x Prop Gain] is set to some value below the

point where the PID begins to go unstable.

2. Adjust the integral gain (leave the proportional gain set as in Step 1).

After a step change in the PID Feedback:

- If the response is too slow (see Slow Response – Over Damped

on

page 234), or the PID Feedback does not become equal to the PID

Reference, decrease A462 or A474 [PID x Integ Time].

- If there is a lot of oscillation in the PID Feedback before settling out

(see Oscillation – Under Damped

on page 235), increase A462 or A474

[PID x Integ Time].

3. At this point, the differential gain may not be needed. However, if after

determining the values for A461 or A473 [PID x Prop Gain] and A462 or

A474 [PID x Integ Time]:

- Response is still slow after a step change, increase A463 or A475 [PID x

Diff Rate].

- Response is still unstable, decrease A463 or A475 [PID x Diff Rate].

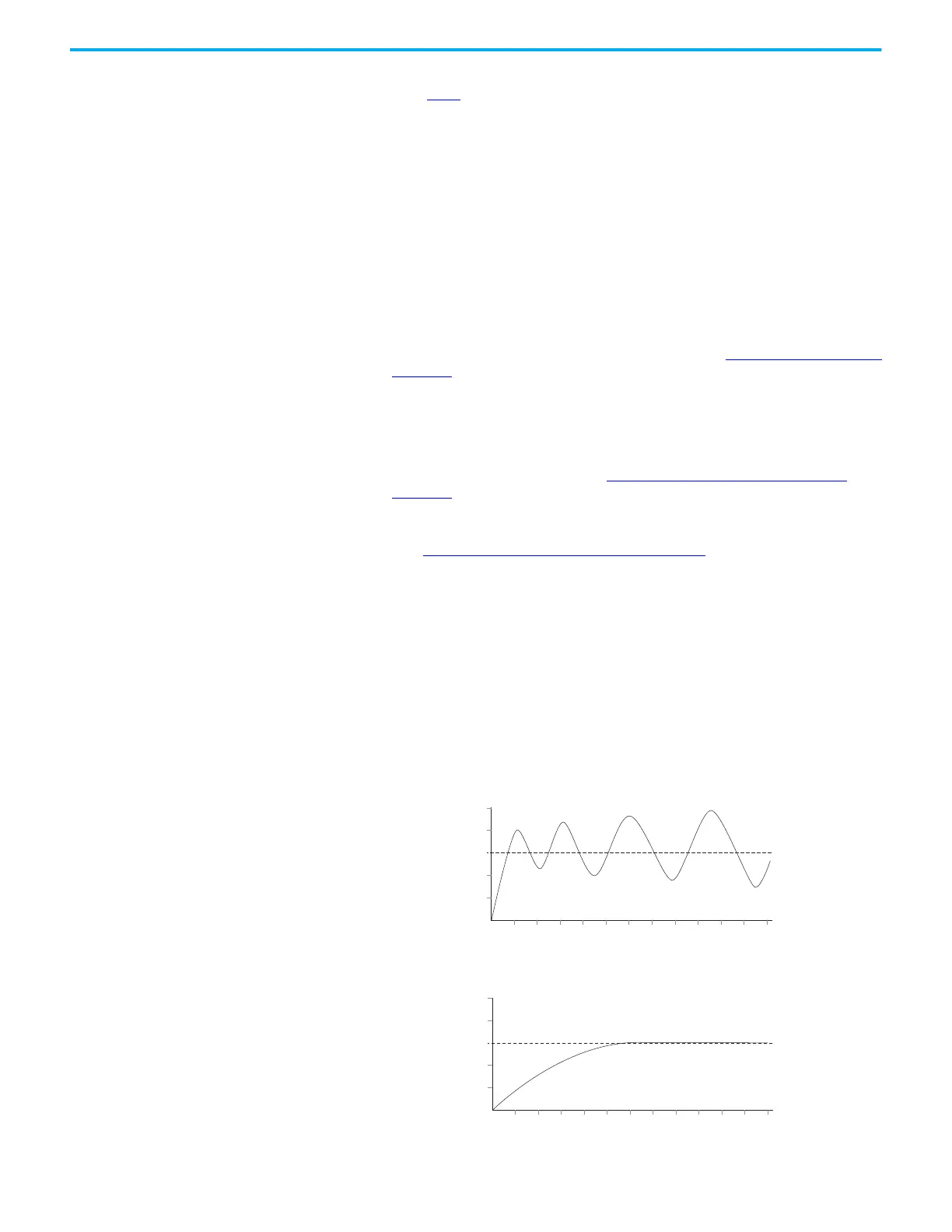

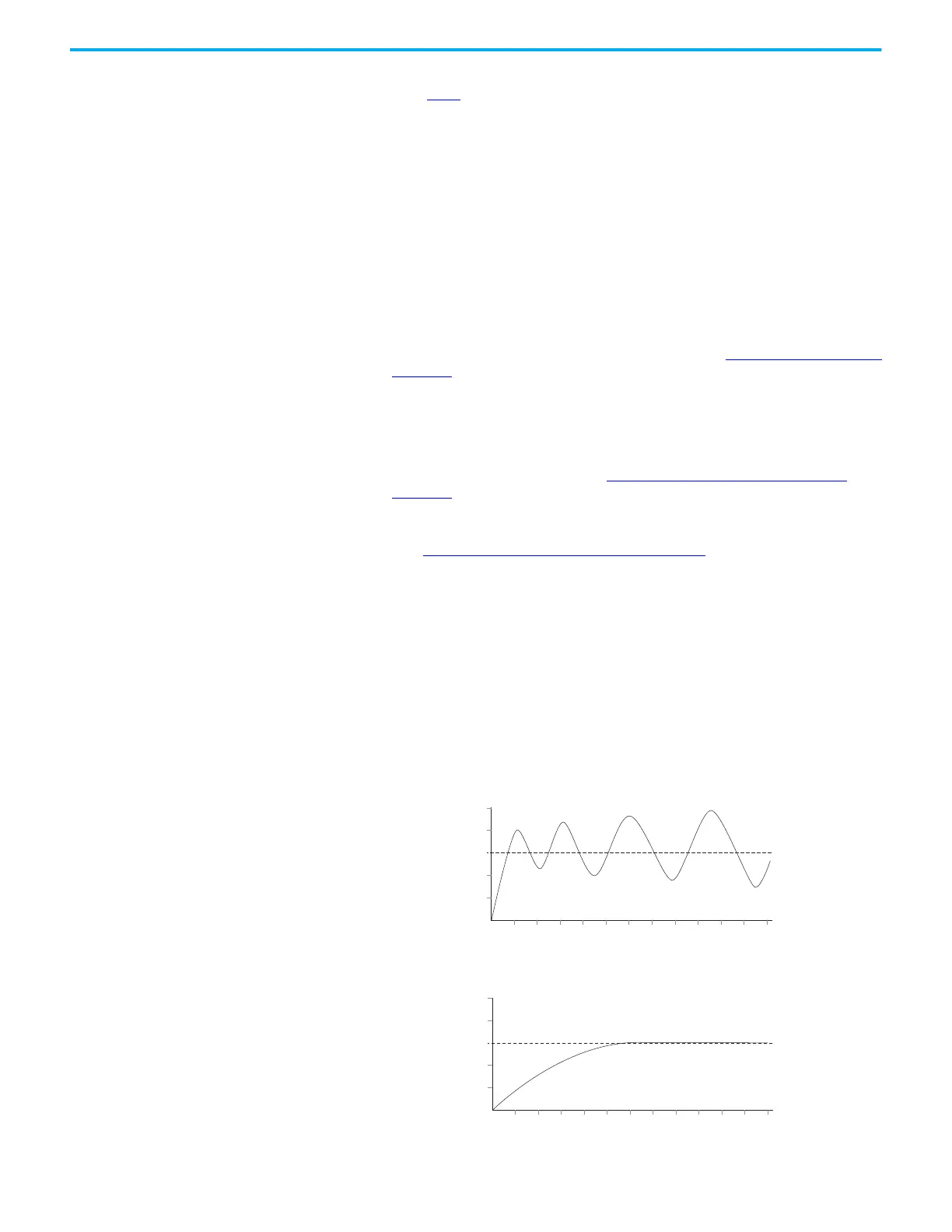

The following figures show some typical responses of the PID loop at different

points during adjustment of the PID Gains.

Unstable Response

Slow Response – Over Damped

PID Feedback

PID Reference

Time

PID Feedback

PID Reference

Time

Loading...

Loading...