242 Rockwell Automation Publication 520-UM001K-EN-E - August 2021

Appendix G Safe Torque Off Function

PowerFlex 525 Safe-

Torque-Off Operation

The PowerFlex 525 Safe-Torque-Off function disables the drive’s output IGBT’s

by breaking the link with the drive microcontroller. When used in combination

with a safety input device, the system satisfies the requirements of EN ISO

13849 and EN62061 for safe-torque-off and helps protect against restart.

Under normal drive operation, both safety inputs (Safety 1 and Safety 2) are

energized, and the drive is able to run. If either input is de-energized, the gate

control circuit becomes disabled. To meet EN ISO 13849 operation, both safety

channels must be de-energized. See the following examples for more

information.

Verify Operation Test the safety function for proper operation after the initial setup of the

PowerFlex 525 Safe-Torque-Off function. Retest the safety function at the

intervals determined by the safety analysis described on page 239

.

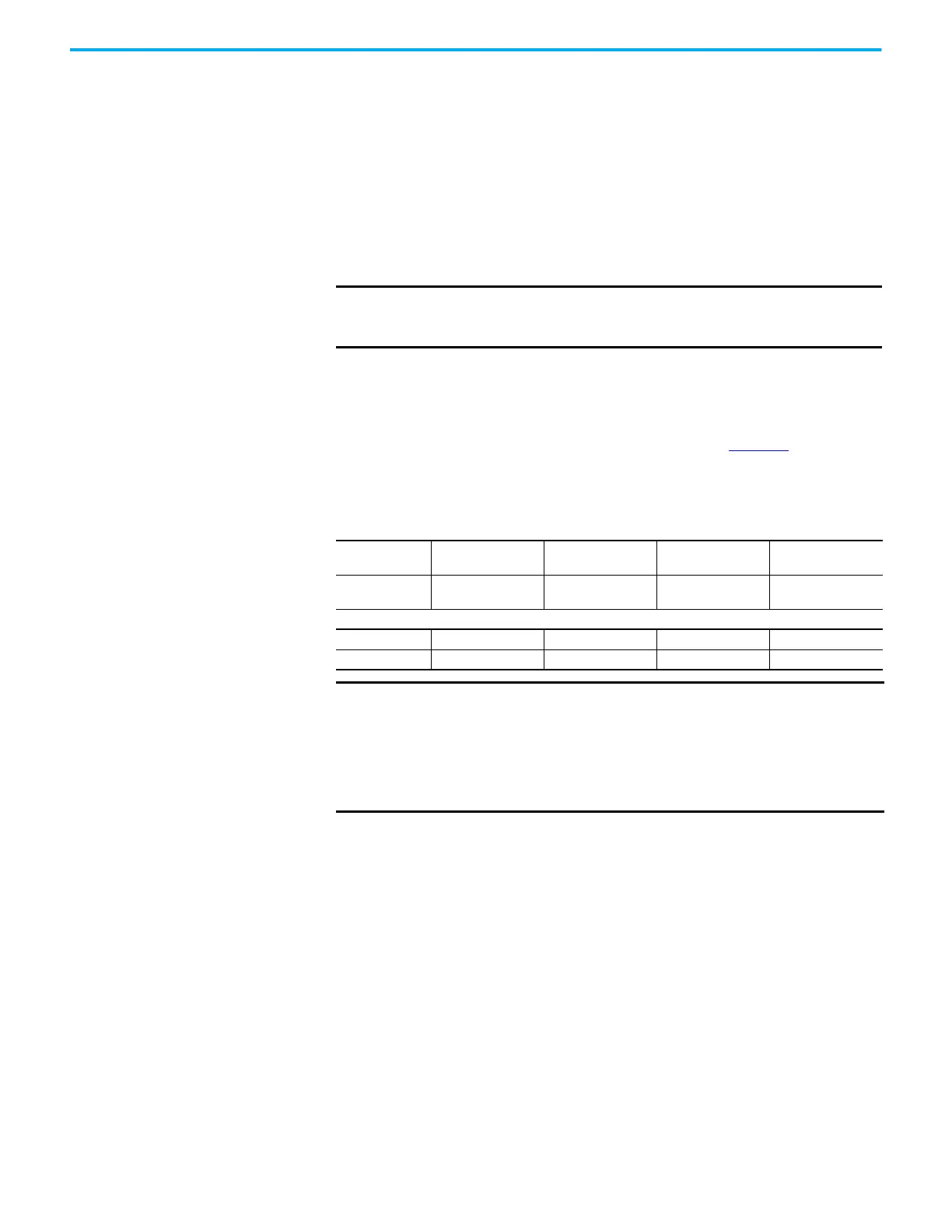

Verify that both safety channels are functioning according to the table below.

Discrepancy Time of the Safety Inputs

For example, if S1 is disabled and S2 did not follow after the discrepancy time,

fault F111 “Safety Hardware” will occur. However, if S1 is disable and S2 follows

before the discrepancy time, fault F059 “Safety Open” will occur.

The discrepancy time is one second for PowerFlex 525 FRN 5.xxx and later. The

discrepancy time is 10 milliseconds for PowerFlex 525 FRN 4.xxx and earlier.

IMPORTANT

By itself, the Safe-Torque-Off function initiates a coast to stop action.

Additional protective measures will need to be applied when an

application requires a change to the stop action.

Channel Operation and Verification

Safety Function

Status

Drive In

Safe State

Drive In

Safe State

Drive In

Safe State

Drive

Able To Run

Drive Status

Configured by t105

[Safety Open En]

Fault F111

(Safety Hardware)

Fault F111

(Safety Hardware)

Ready/Run

Safety Channel Operation

Safety Input S1 No Power Applied Power Applied No Power Applied Power Applied

Safety Input S2 No Power Applied No Power Applied Power Applied Power Applied

IMPORTANT

If an external fault is present on the wiring or circuitry controlling the

Safety 1 or Safety 2 inputs for a period of time, the Safe-Torque-Off

function may not detect this condition. When the external fault

condition is removed the Safe-Torque-Off function will allow an enable

condition. Fault in the external wiring shall either be detected by

external logic, or excluded (wiring must be protected by cable ducting or

armoring), according to EN ISO 13849-2.

Loading...

Loading...