Rockwell Automation Publication 7000-UM202H-EN-P - November 2023 87

Chapter 2 Power Component Definition and Maintenance

Uniform Clamping Pressure Always maintain proper pressure on the thyristors. Follow this procedure

whenever changing devices or loosening the clamp completely.

1. Apply a thin layer of electrical joint compound (Alcoa EJC No. 2 or

approved equivalent) to the clamp head pressure pad face (Figure 80

).

Apply the compound using a small brush, and gently wipe the pad face

with an industrial wipe until a thin film remains. Ensure no brush

bristles remain.

2. Torque the heatsink bolts to 13.5 N•m (10 lb•ft.), then loosen each bolt two

complete turns.

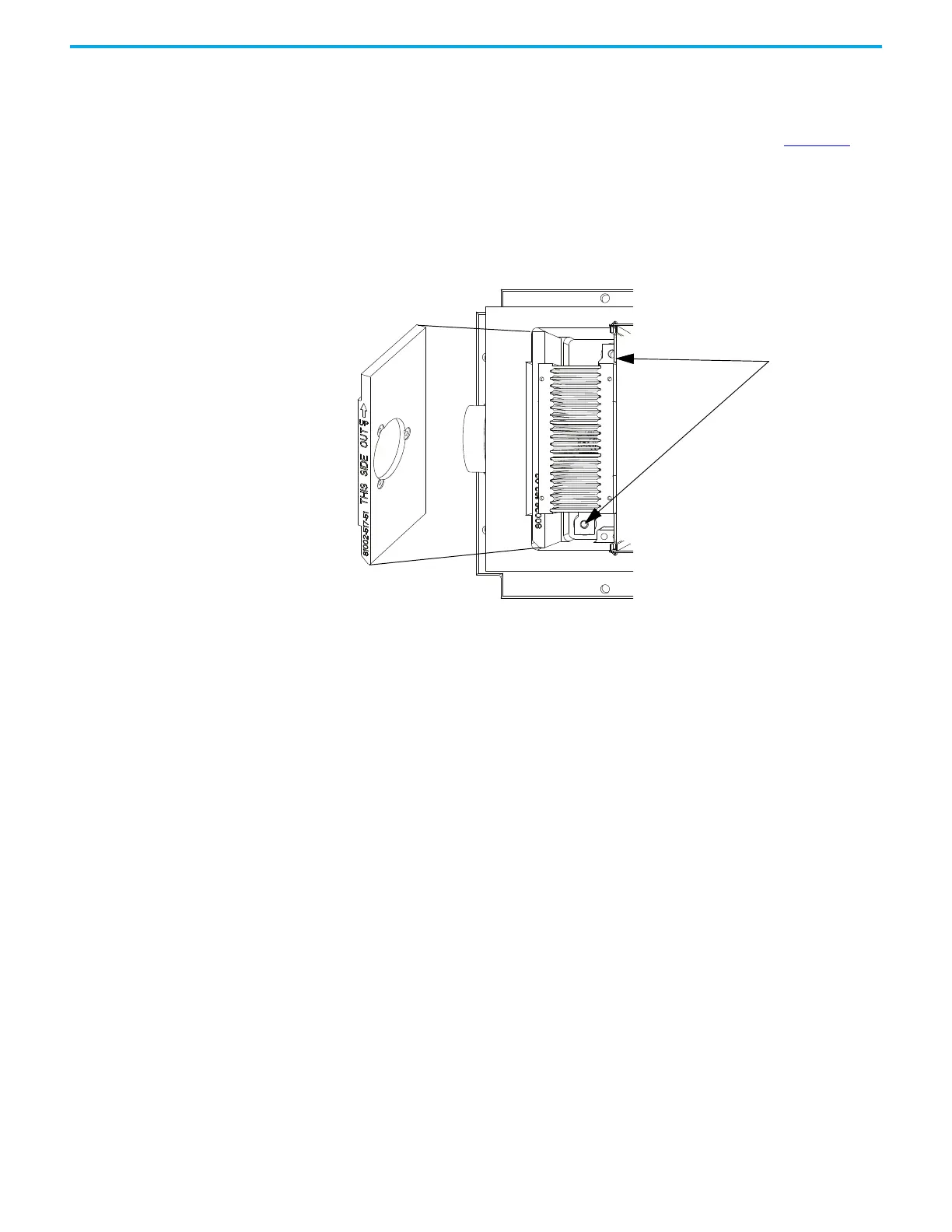

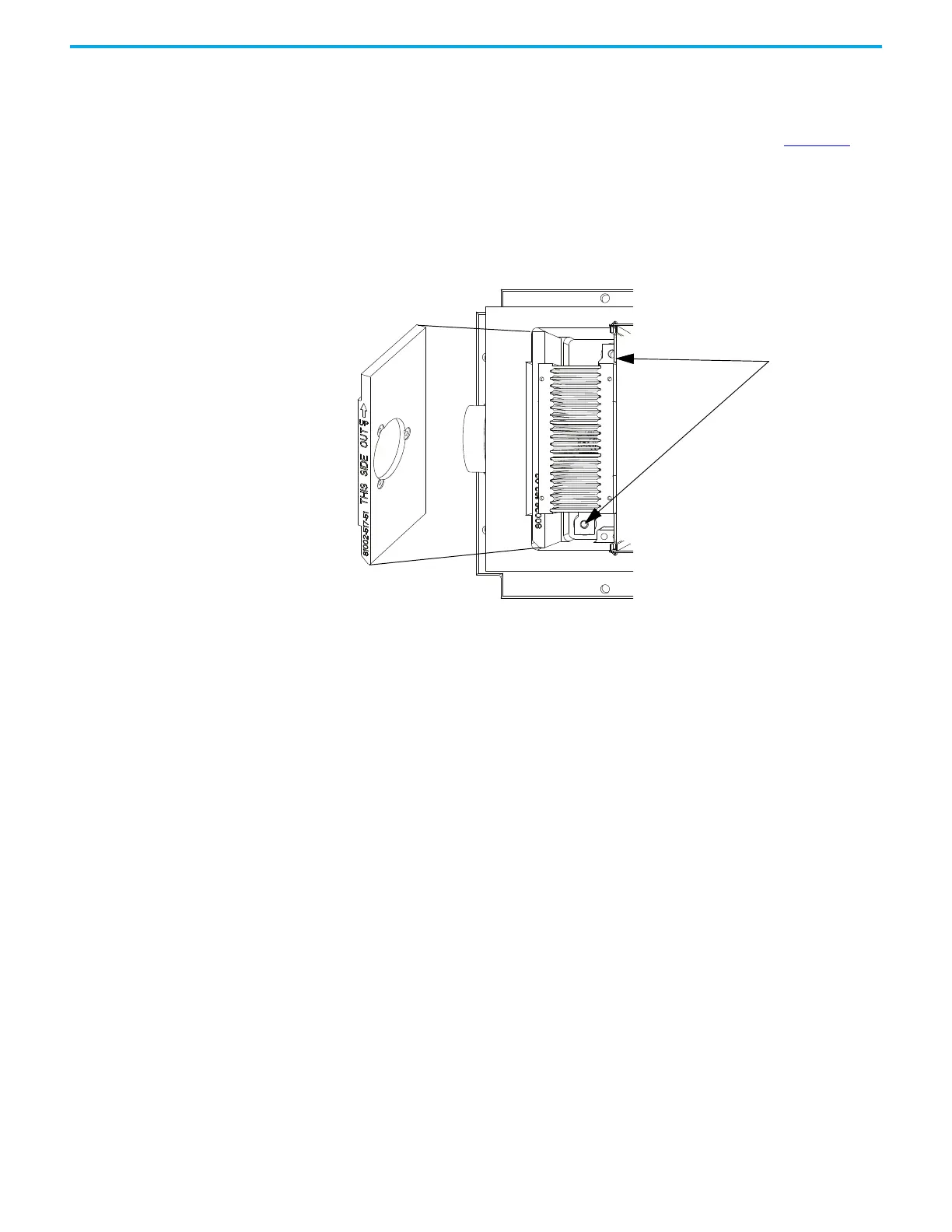

Figure 79 - Location of Heatsink Bolts

3. Tighten the clamp to the proper force until you can turn the indicating

washers by the fingers with some resistance.

4. Torque the heatsink bolts to 13.5 N•m (10 lb•ft) starting with the center

heatsink and moving outward alternating left to right.

5. Check the clamp indicating washer.

Heatsink bolt location

Do NOT remove the pivot plate from

the PowerCage when changing

devices. If the pivot plate is

removed from the PowerCage,

install it in the proper orientation

per the stamping on the side.

Loading...

Loading...