Reference Manual

00809-0100-4809, Rev DA

Appendix A: Specifications and Reference Data

September 2015

133

Specifications and Reference Data

FOUNDATION Fieldbus function block execution times

F

OUNDATION Fieldbus parameters

Standard function blocks

Resource block

Contains hardware, electronics, and diagnostic

information.

Transducer block

Contains actual sensor measurement data including

the sensor diagnostics and the ability to trim the

pressure sensor or recall factory defaults.

LCD block

Configures the local display.

2 Analog input blocks

Processes the measurements for input into other

function blocks. The output value is in engineering

units or custom and contains a status indicating

measurement quality.

PID block

Contains all logic to perform PID control in the field

including cascade and feedforward.

Backup Link Active Scheduler (LAS)

The transmitter can function as a Link Active Scheduler if

the current link master device fails or is removed from the

segment.

Advanced control function block suite

(option code A01)

Input selector block

Selects between inputs and generates an output using

specific selection strategies such as minimum,

maximum, midpoint, average, or first “good.”

Arithmetic block

Provides pre-defined application-based equations

including flow with partial density compensation,

electronic remote seals, hydrostatic tank gauging,

ratio control, and others.

Signal characterizer block

Characterizes or approximates any function that

defines an input/output relationship by configuring up

to twenty X, Y coordinates. The block interpolates an

output value for a given input value using the curve

defined by the configured coordinates.

Integrator block

Compares the integrated or accumulated value from

one or two variables to pre-trip and trip limits and

generates discrete output signals when the limits are

reached. This block is useful for calculating total flow,

total mass, or volume over time.

F

OUNDATION Fieldbus diagnostics suite

(option code D01)

The 3051C F

OUNDATION Fieldbus Diagnostics provide

Abnormal Situation Prevention (ASP) indication. The

integral statistical process monitoring (SPM) technology

calculates the mean and standard deviation of the process

variable 22 times per second. The 3051C ASP algorithm

uses these values and highly flexible configuration options

for customization to many user-defined or application

specific abnormal situations. The detection of plugged

impulse lines is the first available predefined application.

Low power (output code M)

Output

Three wire 1–5 Vdc or 0.8–3.2 Vdc (option Code C2)

user-selectable output. Also user selectable for linear or

square root output configuration. Digital process variable

superimposed on voltage signal, available to any host

conforming to the HART protocol. Low-power transmitter

operates on 6–12 Vdc with no load.

Power consumption

3.0 mA, 18–36 mW

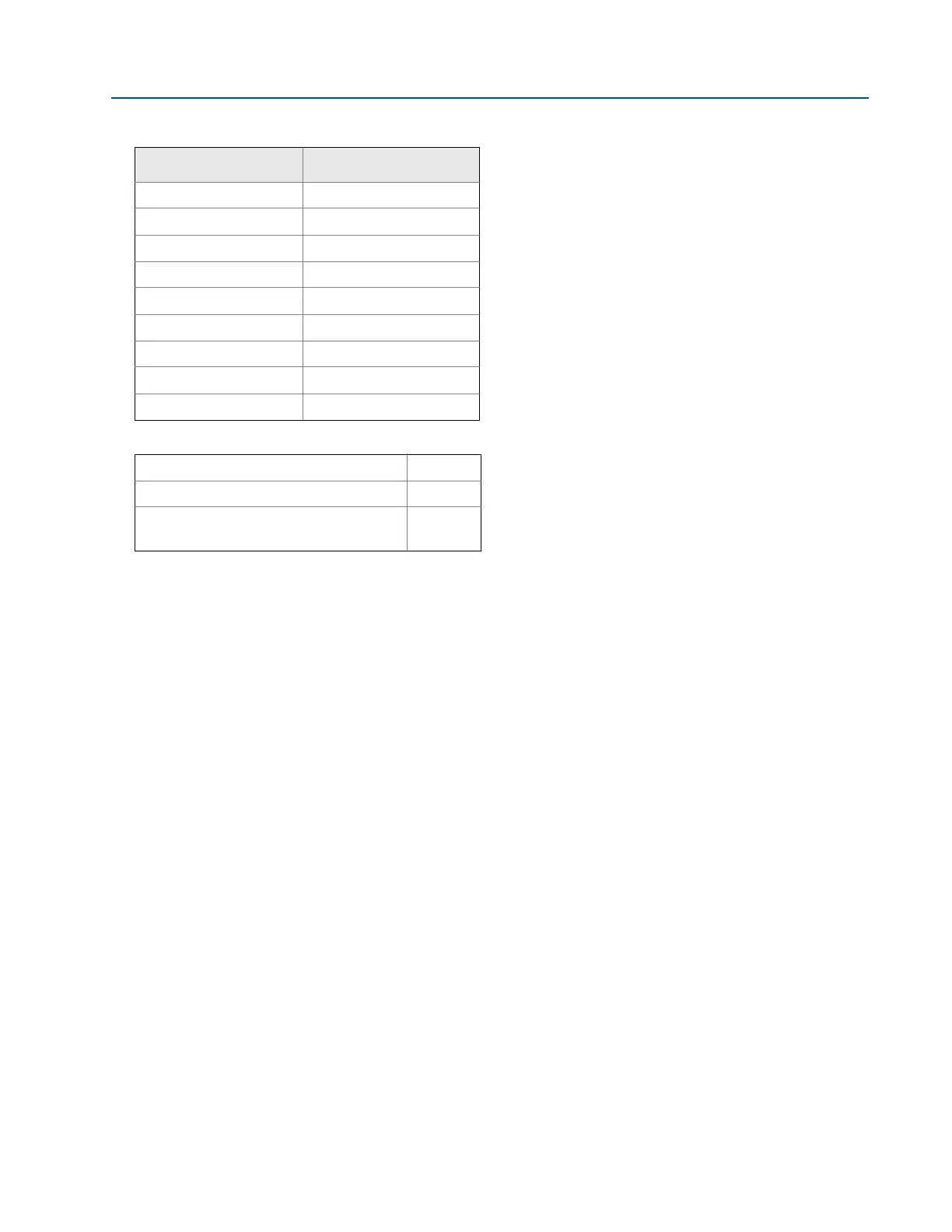

Block Execution time

Resource N/A

Trans ducer N/A

LCD Block N/A

Analog Input 1, 2 30 milliseconds

PID 45 milliseconds

Input Selector 30 milliseconds

Arithmetic 35 milliseconds

Signal Characterizer 40 milliseconds

Integrator 35 milliseconds

Schedule Entries 7 (max.)

Links 20 (max.)

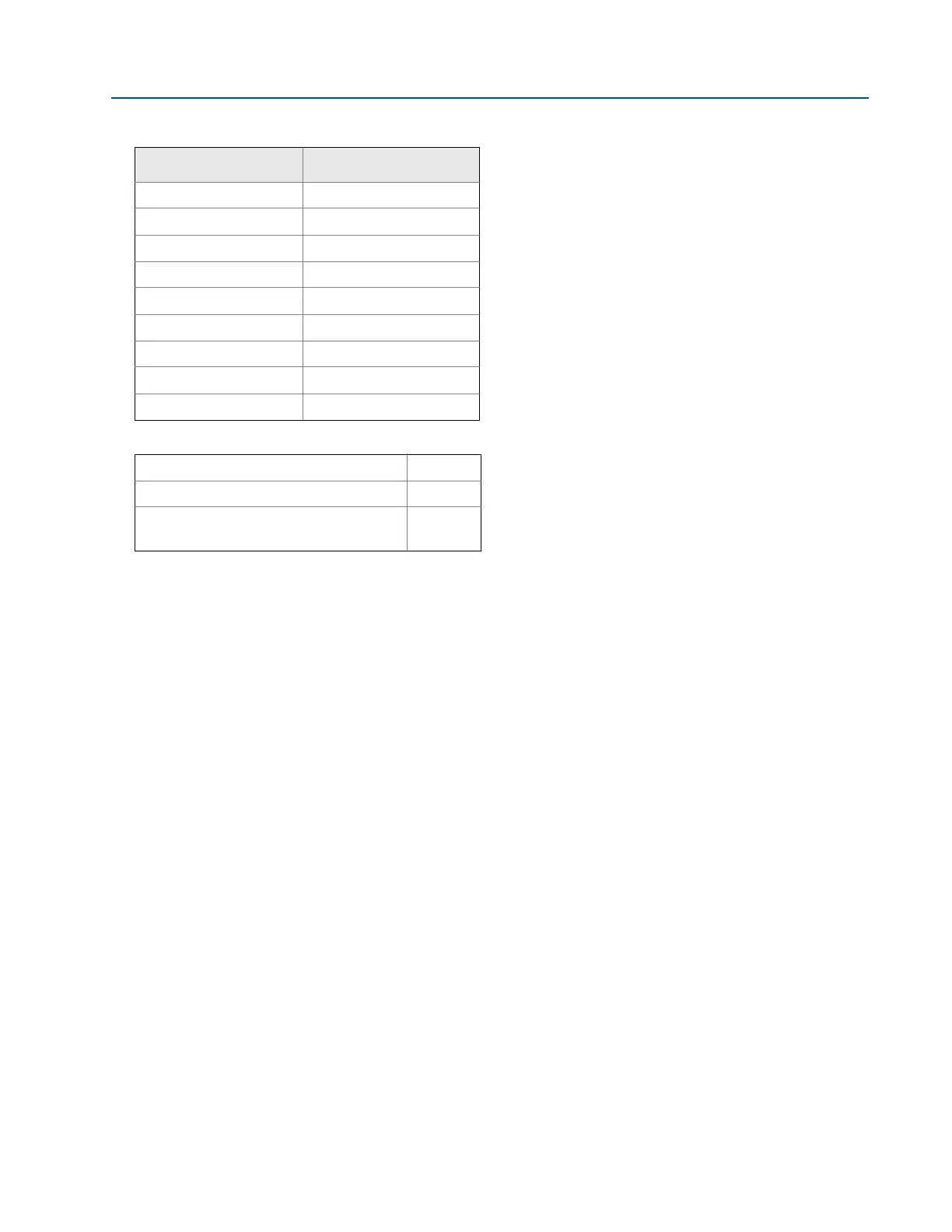

Virtual Communications Relationships

(VCR)

12 (max.)

Loading...

Loading...