Reference Manual

00809-0100-4809, Rev DA

Section 5: Troubleshooting

September 2015

83

Troubleshooting

Section 5 Troubleshooting

Basic troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 83

Return of materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 85

5.1 Basic troubleshooting

If a malfunction is suspected despite the absence of a diagnostic message on the communicator

display, follow the procedures described below to verify that the flowmeter hardware and

process connections are in good working order. Always approach the most likely and

easiest-to-check conditions first.

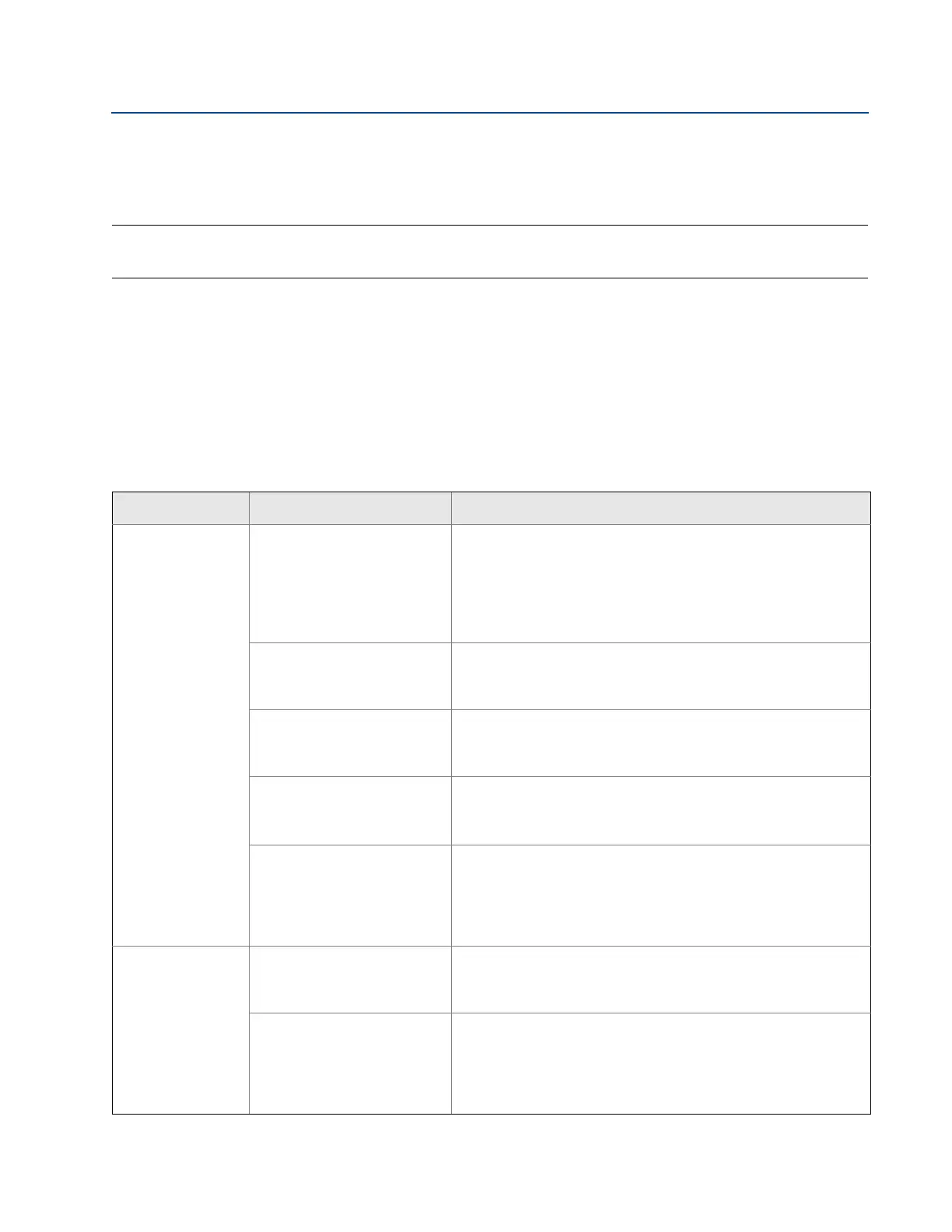

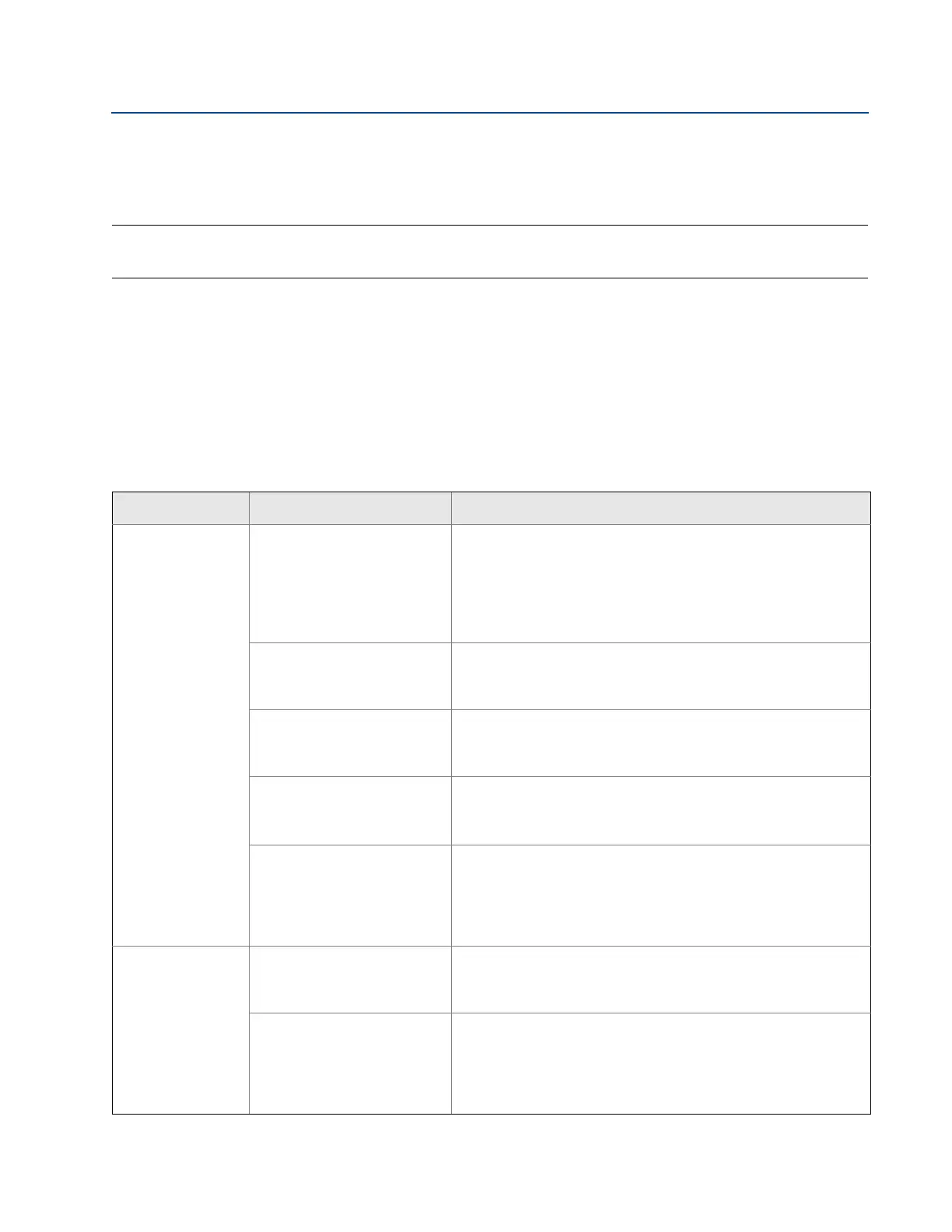

Table 5-1. Troubleshooting Guide

Symptom Possible cause Corrective action

Low Reading

Annubar sensor not fully

installed (not spanning the

inner diameter of the pipe)

•Verify the actual pipe ID and wall dimensions and compare to the

Calculation Data Sheet.

•Consult Factory if dimensions do not match.

•During re-installation mark tip of Annubar

®

sensor, install, remove

and inspect marking to insure contact with opposite side of the

pipe.

Annubar sensor not aligned

properly in flow profile

•Refer to the installation instructions in Section 2: Installation of this

manual for proper alignment straight across pipe I.D., with

upstream sensing holes facing straight upstream in flow profile.

Annubar sensor not installed

in proper pipe size

•Verify the actual pipe ID and wall dimensions and compare to the

Calculation Data Sheet.

•Consult Factory if dimensions do not match.

Annubar sensor installed too

close to an upstream flow

disturbance, such as a pipe

elbow.

•Compare installation to recommended straight pipe run

referenced in the installation instructions in Section 2: Installation

of this manual.

DP Transmitter not zeroed

properly, or not configured

correctly

•Verify DP sensor has been zeroed properly.

•Verify transmitter range is correct, and if square root output is

correct.

•Verify Annubar sensor calc sheet represents fluid density properly

so that transmitter is configured correctly for the application.

High Reading

Annubar sensor not installed

in proper pipe size

•Verify the actual pipe ID and wall dimensions and compare to the

Calculation Data Sheet.

•Consult Factory if dimensions do not match.

DP transmitter not zeroed

properly or not configured

properly

•Verify DP sensor has been zeroed properly.

•Verify transmitter range is correct, and if square root output is

correct.

•Verify Annubar sensor calc sheet represents fluid density properly

so that transmitter is configured correctly for the application.

Loading...

Loading...