79

Reference Manual

00809-0100-4809, Rev DA

Section 4: Operation and Maintenance

September 2015

Operation and Maintenance

4.3 Pak-Lok, Flange-Lok, and Flo-Tap maintenance

The Pak-Lok, Flange-Lok, and Flo-Tap models utilize a packing gland mechanism to sustain a seal

on the process fluid. Periodically the packing rings need to be checked to ensure that they are

continuing to seal properly.

Check the packing gland for leaks. If a leak is present, check that the nuts are tightened

down on the packing studs. If the leak persists, then the packing rings should be

replaced.

If the process fluid goes through large degrees of temperature cycling, verify that the

packing is tightened down sufficiently and that the tip of the Annubar sensor is still

secured against the opposite side pipe wall. A leak would indicate the packing has

loosened. Also, excessive vibration of the Pak-Lok, Flange-lok, or Flo-tap model could

indicate the tip of the sensor is no longer secured to the pipe wall. For the Pak-lok or

Flange-lok models, re-tighten the nuts to ensure that the packing is sufficiently

tightened and that the tip of the Annubar sensor is still secured against the opposite

side pipe wall. For the Flo-tap models, tighten the drive nuts or rotate the crank

clockwise until the sensor is secured against the opposite side pipe wall. Re-tighten the

packing gland nuts to ensure that the packing is sufficiently tightened.

If there is excessive vibration present in the Annubar sensor, immediate attention is

required as the sensor may no longer be secured against the opposite side pipe wall.

This could result in the sensor bending, cracking, or breaking. For the Pak-lok or

Flange-lok models, re-tighten the nuts to ensure that the packing is sufficiently

tightened and that the tip of the Annubar sensor is still secured against the opposite

side pipe wall. For the Flo-tap models, tighten the drive nuts or rotate the crank

clockwise until the sensor is secured against the opposite side pipe wall. Re-tighten the

packing gland nuts to ensure that the packing is sufficiently tightened. If excessive

vibration is still present, contact an Emerson

™

Process Management representative.

If the packing rings appear brittle, old, or compressed beyond further use, a new set of

rings should be ordered for replacement. Installation instructions can be found in

Section 2: Installation of this manual.

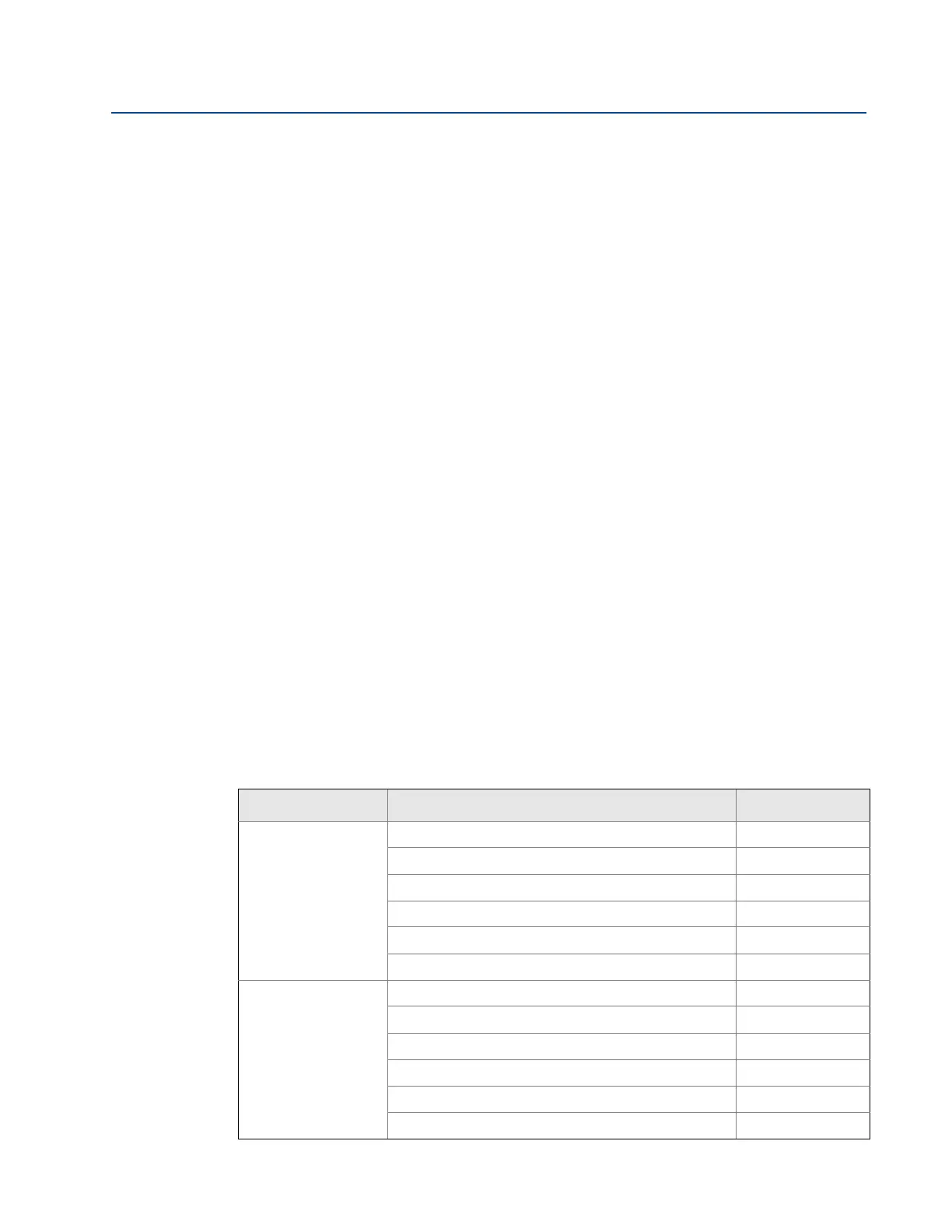

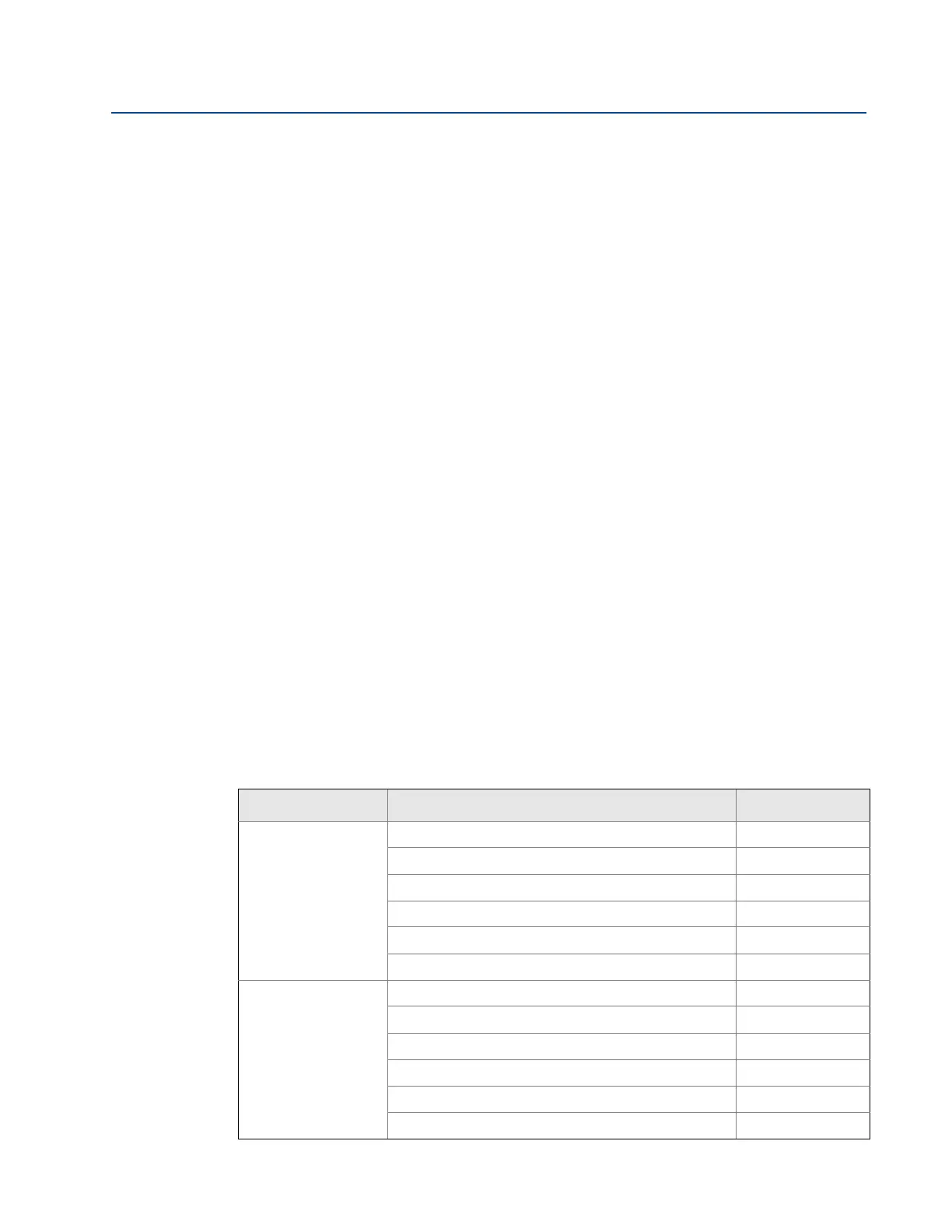

Table 4-1. Replacement Part Numbers for Pak-Lok, Flange-Lok, and Flo-Tap Packing

Model Packing kits Part number

Pak-Lok or Flange-Lok

Sensor Size 1 Grafoil (Standard) 28-503002-920

Sensor Size 2 Grafoil (Standard) 28-503002-921

Sensor Size 3 Grafoil (Standard) 28-503002-922

Sensor Size 1 PTFE (Option P2) 28-503002-910

Sensor Size 2 PTFE (Option P2) 28-503002-911

Sensor Size 3 PTFE (Option P2) 28-503002-912

Flo-tap

485 Sensor Size 1 Grafoil (Standard) 28-505010-900

485 Sensor Size 2/585 Sensor Size 22 Grafoil (Standard) 28-505010-901

485 Sensor Size 3/585 Sensor Size 44 Grafoil (Standard) 28-505010-902

485 Sensor Size 1 PTFE (Option P2) 28-505010-910

485 Sensor Size 2/585 Sensor Size 22 PTFE (Option P2) 28-505010-911

485 Sensor Size 3/585 Sensor Size 44 PTFE (Option P2) 28-505010-912

Loading...

Loading...