81

Reference Manual

00809-0100-4809, Rev DA

Section 4: Operation and Maintenance

September 2015

Operation and Maintenance

4. Purge with dry air (less than 5% moisture by weight).

5. Stainless steel purge tubing should have a minimum of

1

/2-in. (12.5 mm) O.D. and at

least 0.035-in. (0.89 mm) wall thickness. Care must be taken to protect the secondary

instrumentation from high pressures and temperatures when purging an Annubar

primary element. Ear protection is also recommended for all personnel in the vicinity of

the system being purged. See figure for sample set-up.

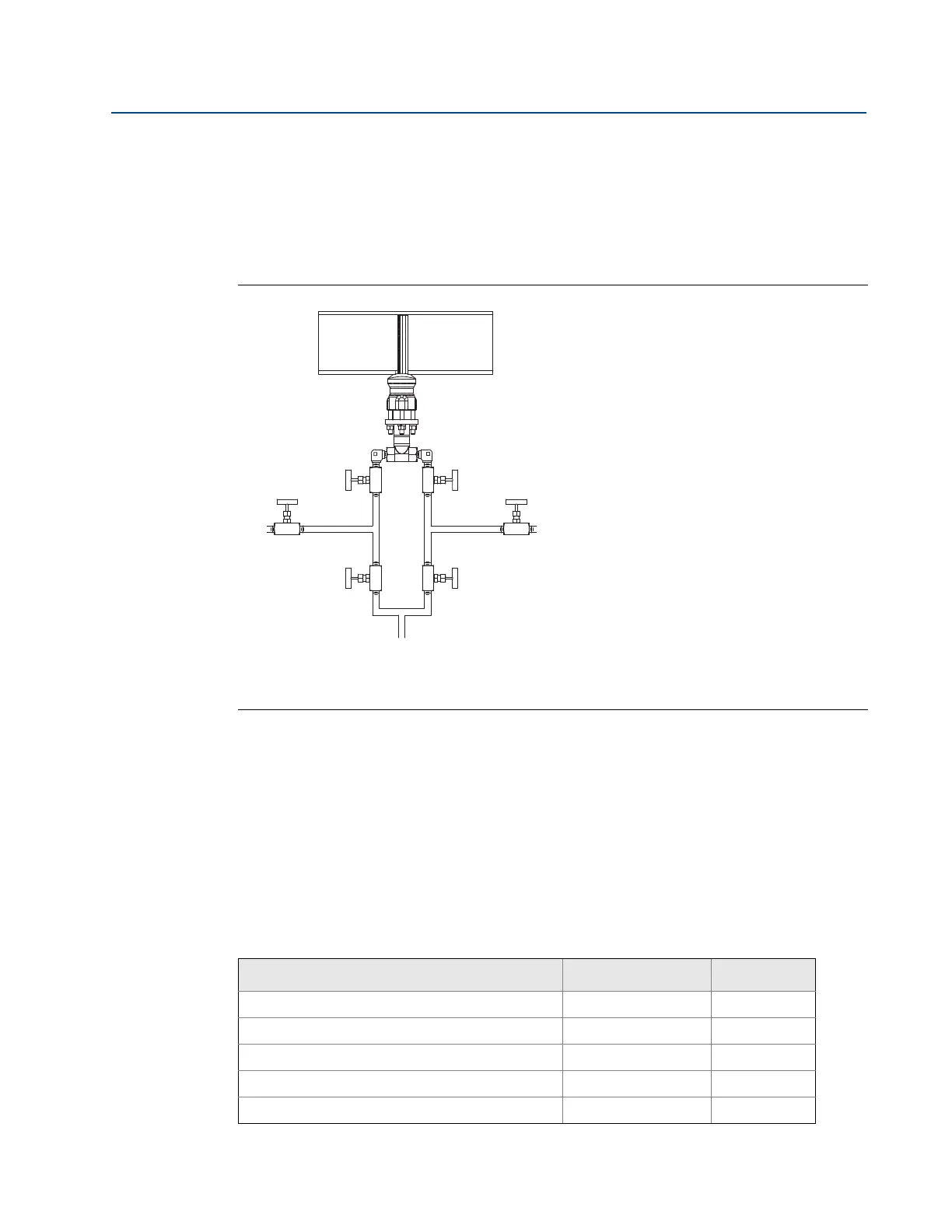

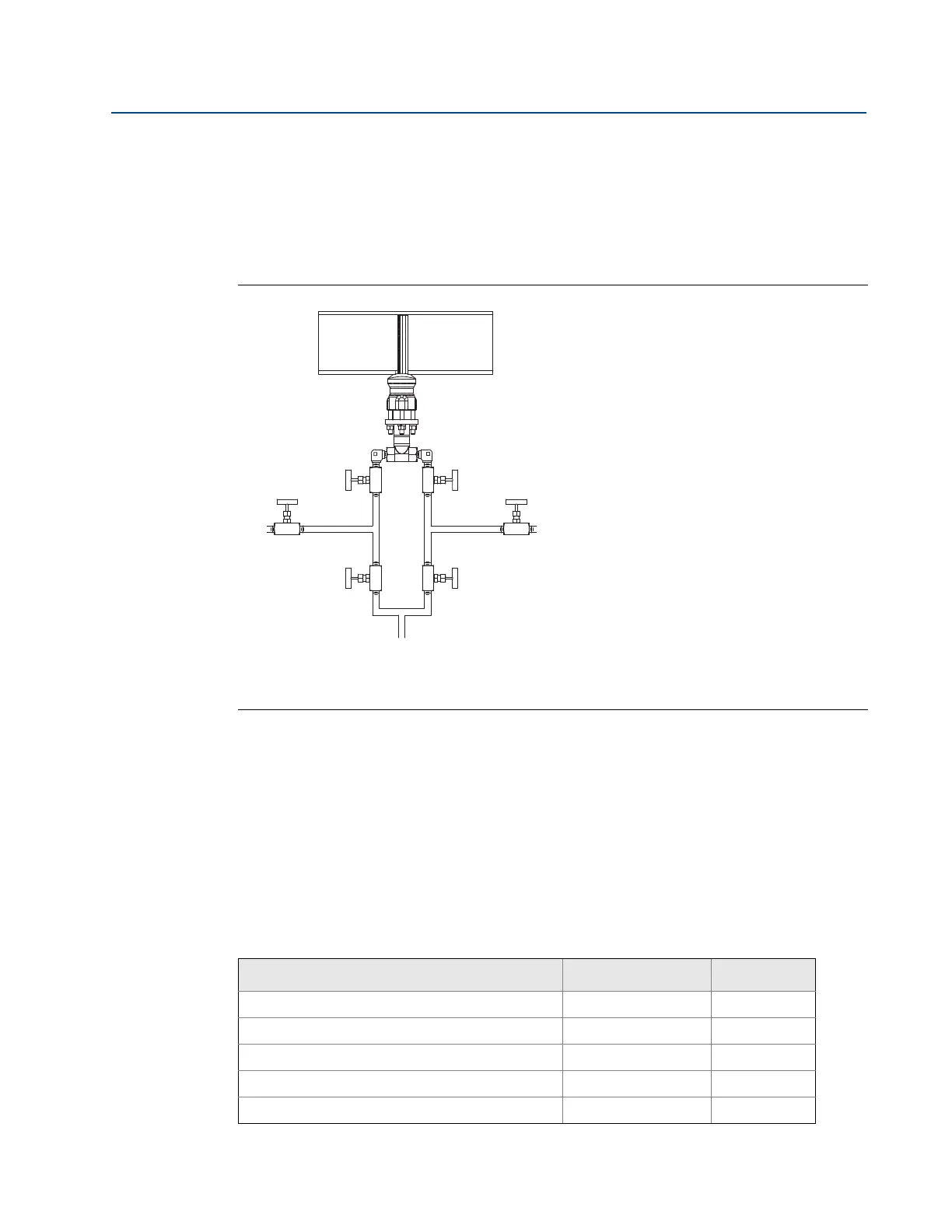

Figure 4-4. Impulse Tube Arrangement for Purge

A. To high side of secondary element

B. To low side of secondary element

C. To external source of fluid pressure

4.6 Main steam line Annubar sensor maintenance

Due to the extreme conditions that the Rosemount

®

585 Main Steam Line Annubar Flowmeters

come into contact with, it should be removed and inspected annually to check for wear.

Emerson Process Management recommends a visual inspection and a Dye Penetrant; examine

to identify any cracks or wear on the Annubar sensor. After the Annubar sensor is inspected, it is

recommended to replace the packing rings to ensure a proper seal. Tab le 4 -1 shows the

replacement part numbers for the packing rings and other spare parts.

Table 4-2. Replacement Part Numbers for the Packing Rings and Other Spare Parts

Packing kits Part number Quantity

Packing Rings – Split 19006-67 2

Packing Rings – Solid Carbon/Graphite 19006-04 3

Packing Gland Stud 16147-07 16

Packing Gland/Support Plate Nuts 16068-06 16

Support Plate Lock Washers 00-101005-01 8

Loading...

Loading...