BRP-Rotax

MAINTENANCE MANUAL LINE

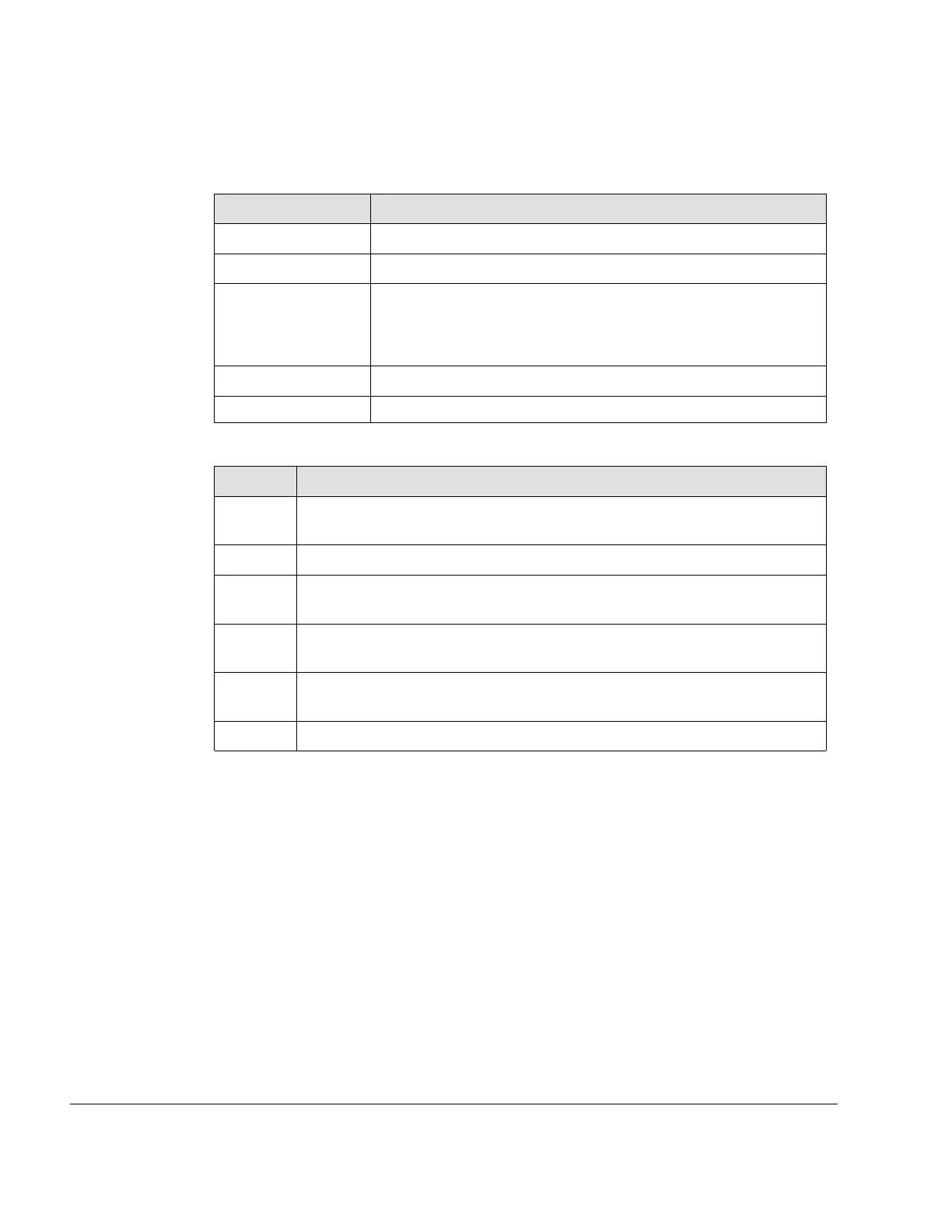

Special tools To measure the differential pressure the following special tools and equipment are

necessary.

Part number Description

n.a.

Compressed air approx. 6 bar (80 psi).

n.a

2 pressure gauges.

n.a

Orifice jet*, of 1 mm (0.04 in) inner diameter and 3 mm (0.12 in)

length. * or equivalent e.g. orifice diameter 0.040 in., long 0.0250

in., 60° degree approach angle according to AC43.13, latest

issue.

n.a

Adapter to spark plug thread.

n.a

Connect line.

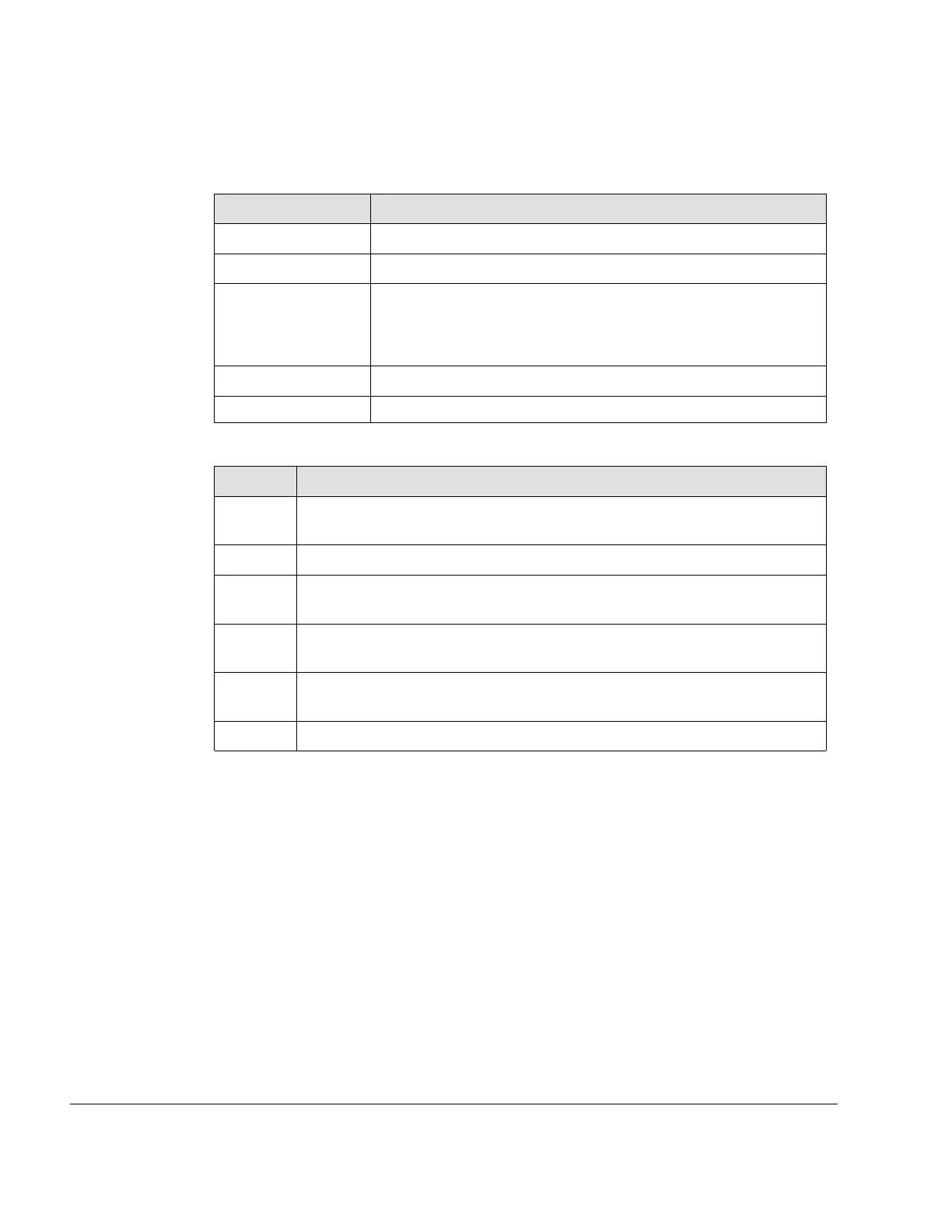

Instruction Testing is carried out using the differential pressure test procedure.

Step

Procedure

1 Operate the engine until the temperatures have stabilized for a period of 5

min (engine oil temperature between 50 to 70 °C (122 - 160 °F).

2

Starting with cylinder head 1 move piston to TDC position.

3 Remove the upper spark plugs. Prevent dirt or other foreigner particles from

penetrating the engine (A).

4

Screw adaptor (1) into the spark plug thread and connect up the two pres-

sure gauges (2) with the orifice jet (3) between them (B).

5

Now put constant pressure, between 5.5-6 bar (80 psi) on the line and take

readings at pressure gauge (C)..

6 Repeat this proceeding at all 4 cylinder heads.

Value The maximum permissible pressure drop is 25 %, e.g. from 6 to 4.5 bar (80 psi to 65 psi)

(D).

If the pressure loss is less than 25% then the valve seats and piston rings are working

properly. The spark plug has to be installed according to Chapter 12–20–00 section Instal-

lation of spark plugs.

If the value is over 25% inspection, repair or overhaul must be carried out in accordance

with the BRP-Rotax instructions for continued airworthiness.

• Detailed inspection of affected engine components.

12–20–00

Page 8

September 01/2018

Effectivity: 912 i Series

Edition 2/Rev. 0

Loading...

Loading...