BRP-Rotax

MAINTENANCE MANUAL LINE

MAINTENANCE SCHEDULE

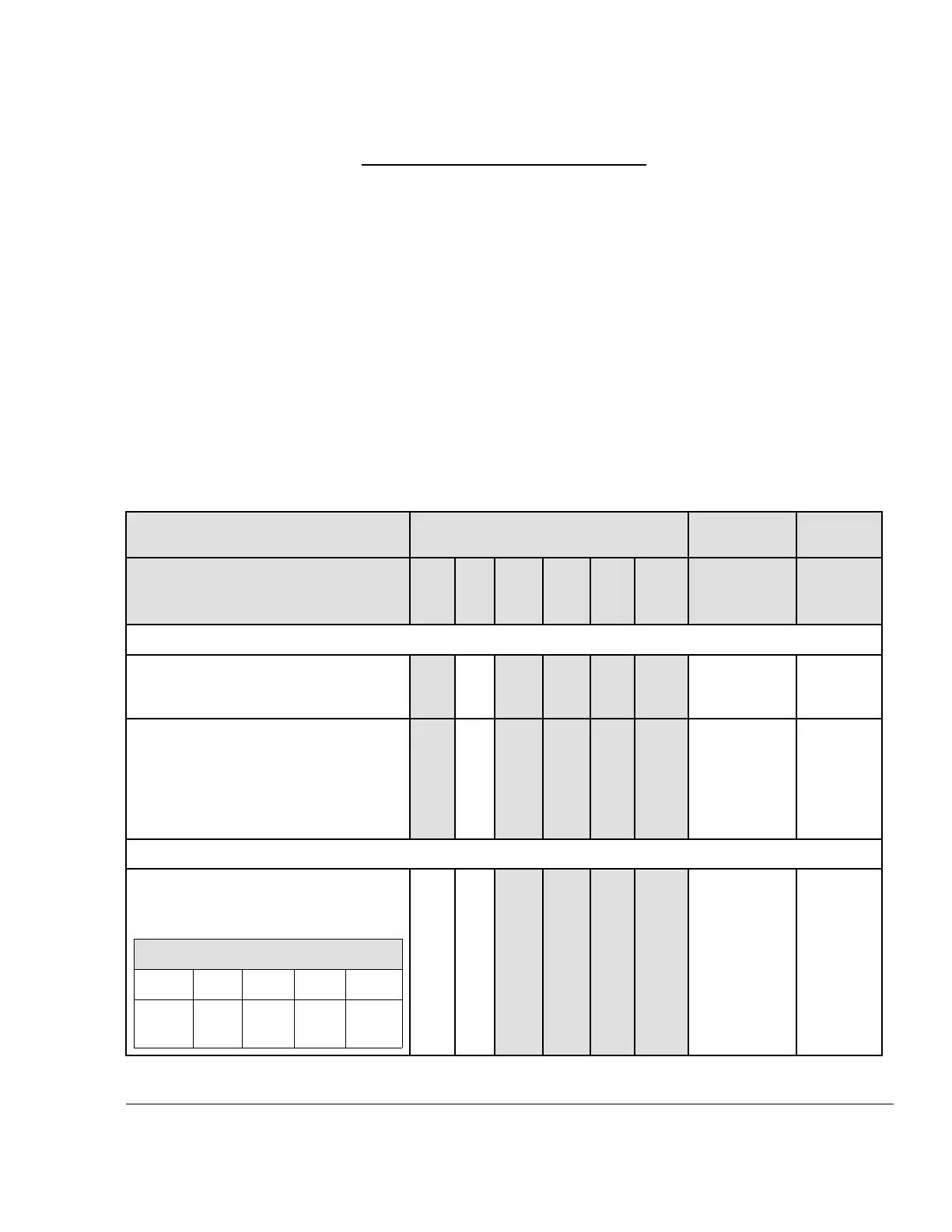

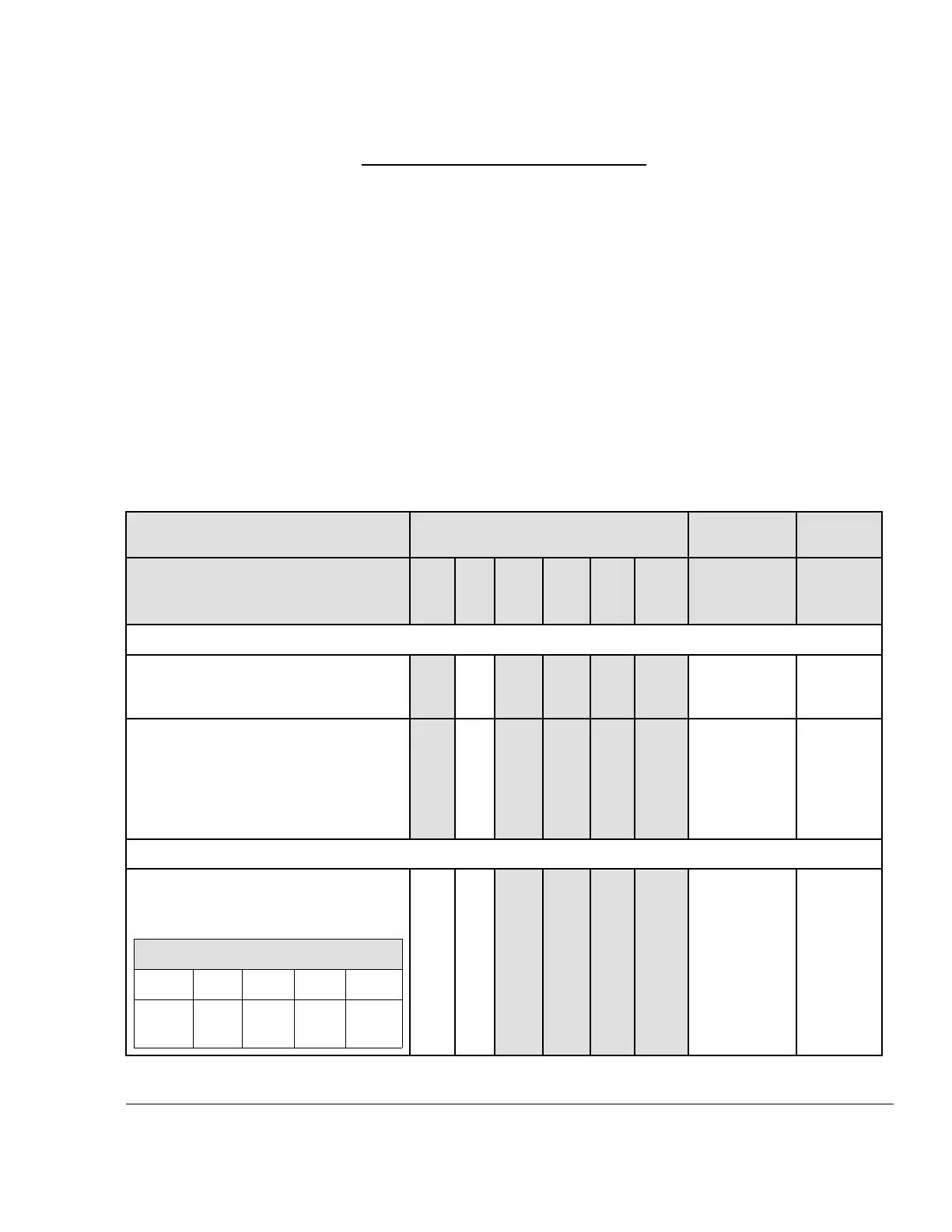

Perform the following maintenance tasks at the intervals shown in the maintenance check list.

See chapter 05-20-00 25 hr. check.

Legend: X

=

do the task

blank

=

no task required

NOTE

If the first 3 are checks (General note, Differential pressure check and Inspection fine fuel filter) are

acceptable then continue with the maintenance schedule.

If one of the first 3 checks are not acceptable, the engine must be checked and repaired in accord-

ance with the BRP-Rotax instructions for continued airworthiness.

Points of Inspection

Interval Operating hours Chapter

Reference

Signa-

ture

* no periodic maintenance require-

ment after the first 25 hours of

operation

25*

50 100 200 600 1000

1) General note

All (Alert) Service Bulletins are com-

plied with. If necessary to perform

these and documented.

X X X X X

All SI-PAC (Service Instruction Part

and Accessories) for additional GENU-

INE-ROTAX® –parts and accessories

used on the relevant aircraft are com-

plied with. If necessary to perform

these and document it.

X X X X X

2) Differential pressure check

Check the compression by the differen-

tial pressure method.

Test pressure________hPa (psi)

Pressure drop (% or fraction)

Cyl. #

1 2 3 4

bar/

psi

X

(1

X X X 12–20–00

Checking the

compression

Effectivity: 912 i Series

Edition 2/Rev. 0

05–20–00

Page 9

September 01/2018

Loading...

Loading...