MX-M700N SIMULATION 7 – 33

43-3

Purpose

Setting (Adjustment)

Function (Purpose)

Fusing motor RPM setting.

Section

Setting

Operation/Procedure

1) Select the number corresponding to the adjustment item with

10-key.

2) Press the [START] key.

3) Enter the setting (adjustment) value with 10-key.

4) Press the [START] key.

Unless special measures are required, do not change the setting

values below.

44

44-1

Purpose

Setting

Function (Purpose)

Used to set enable/disable of correction

operations in the image forming (process)

section.

Section

Image process (Photoconductor/Develop-

ing/Transfer/Cleaning)

Operation/Procedure

1) Each bit (7 kinds) is assigned to each correction item to set

ENABLE/DISABLE of the operation.

Each bit is assigned with 0 or 1 value. Enter the total values of

items which are desired to be valid with the 10-key.

2) Press the [START] key.

NOTE: Set to 222.

When bit=1, correction is made.

NOTE: BIT0 is not displayed, but set to the developing bias correc-

tion function. This setting is forcibly made enable, and can-

not be disabled.

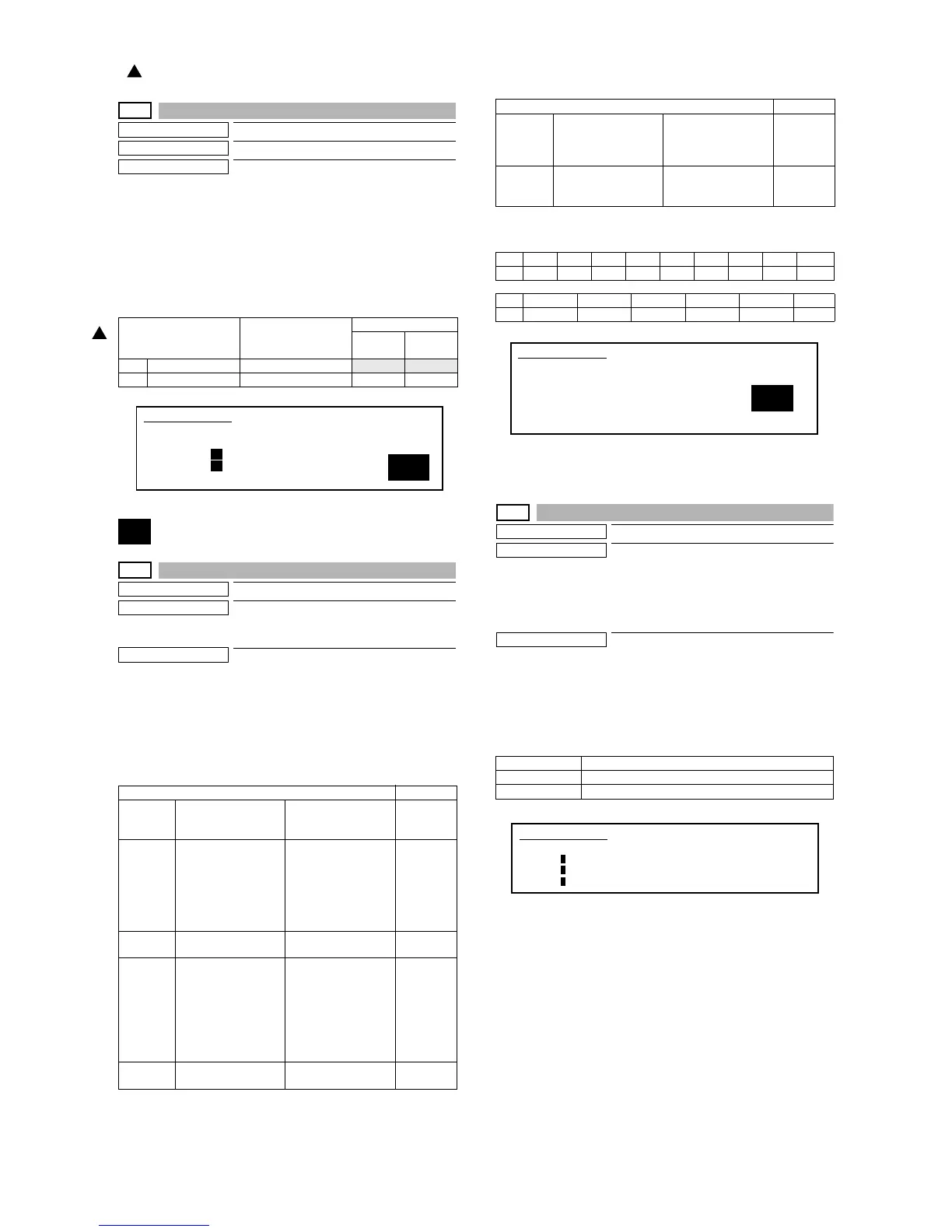

44-2

Purpose

Adjustment

Function (Purpose)

Used to perform the gain adjustment

(image density sensor LED current adjust-

ment) of the image density sensor and the

gain adjustment (OPC drum marking sen-

sor LED current adjustment) of the OPC

drum marking sensor.

Section

Image process (Photoconductor)

Operation/Procedure

Press [START] key, and the adjustment is automatically performed.

When the adjustment is completed, the adjustment result is dis-

played.

If the adjustment is not completed normally, "ERROR" is displayed.

When an error occurs, the adjustment result is not revised.

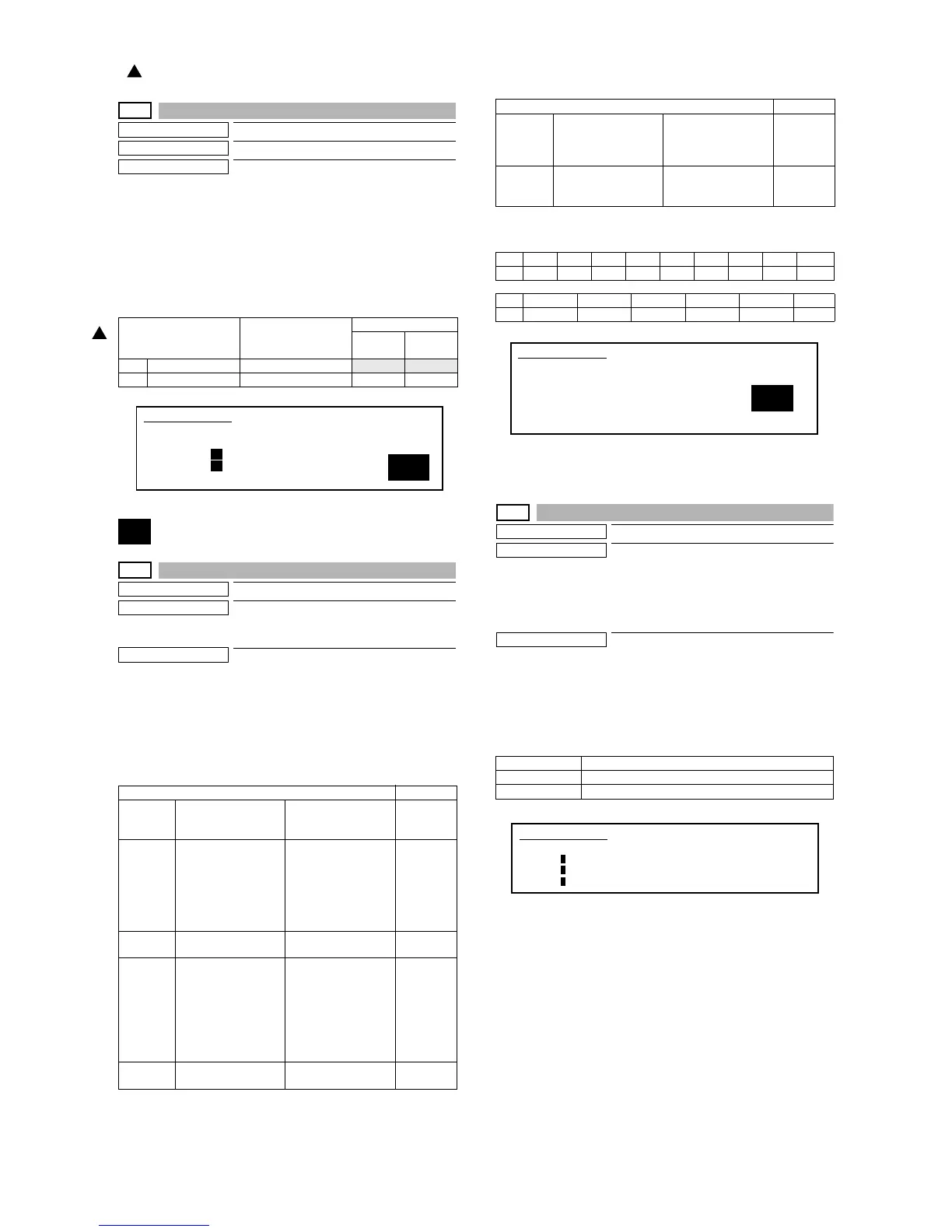

Item Setting range

Default

55/62

(ppm)

70

(ppm)

1NORMAL 0 - 99

34 34

2 SLOWDOWN 0 - 99 46 44

Item Default

BIT1 OPC drum membrane

decrease (sensitivity/

potential) correction

Laser power/main

charger grid voltage

1

BIT2 The range of the toner

patch making voltage

in the developing bias

voltage/main charger

grid voltage correction

is specified. (Voltage

limit)

Developing bias/main

grid voltage (adjusted

by SIM 8-1 and 8-2) +-

100v

1

BIT3 For humidity

correction

Toner concentration

correction

1

BIT4 Toner concentration

correction A

When the developing

bias/main charger grid

voltage correction is

changed more than

the specified level, the

toner concentration

control level is

corrected.

1

BIT5 Toner concentration

correction B

Correction for the

developer life

0

1

SIMULATION 43-3

1

FUSER MOTOR SPEED SETTING. SELECT 1-2, AND PRESS

START.

1. NORMAL 36

2. SLOWDOWN 50

BIT6 Toner concentration

correction C

Toner concentration

correction in low

density image

continuous print

1

BIT7 OPC drum for

environment

correction

1

Bit151413121110 9 8 7

00000000Env

Bit654321

Tcon_C Tcon_B Tcon_A Humidity Pcon_lm Drum

DMLED Drum marking sensor gain adjustment value

PCLED Image density sensor gain adjustment value

DRUM Kind of the drum 0 = Other/1 = SHARP drum

Item Default

SIMULATION 44-1

PROCESS CORRECTION VALUE SETTING. INPUT VALUE 0-999

AND PRESS START.

BIT1: DRUM

BIT2: PROCON_LM BIT3: HUMIDITY

BIT4: TONERCON_A BIT5: TONERCON_B

BIT6: TONERCON_C BIT7: ENVIRONMENT

223

SIMULATION 44-2

PROCON GAIN ADJUSTMENT. PRESS START.

DMLED: 0

PCLED: 0

DRUM : 0

: '07 Feb 15

1

Loading...

Loading...