104 DUSTHUNTER T · Operating Instructions · 8012428 V 2.0 · © SICK MAIHAK GmbH Germany

Malfunctions

The following malfunctions can be removed under circumstances at site.

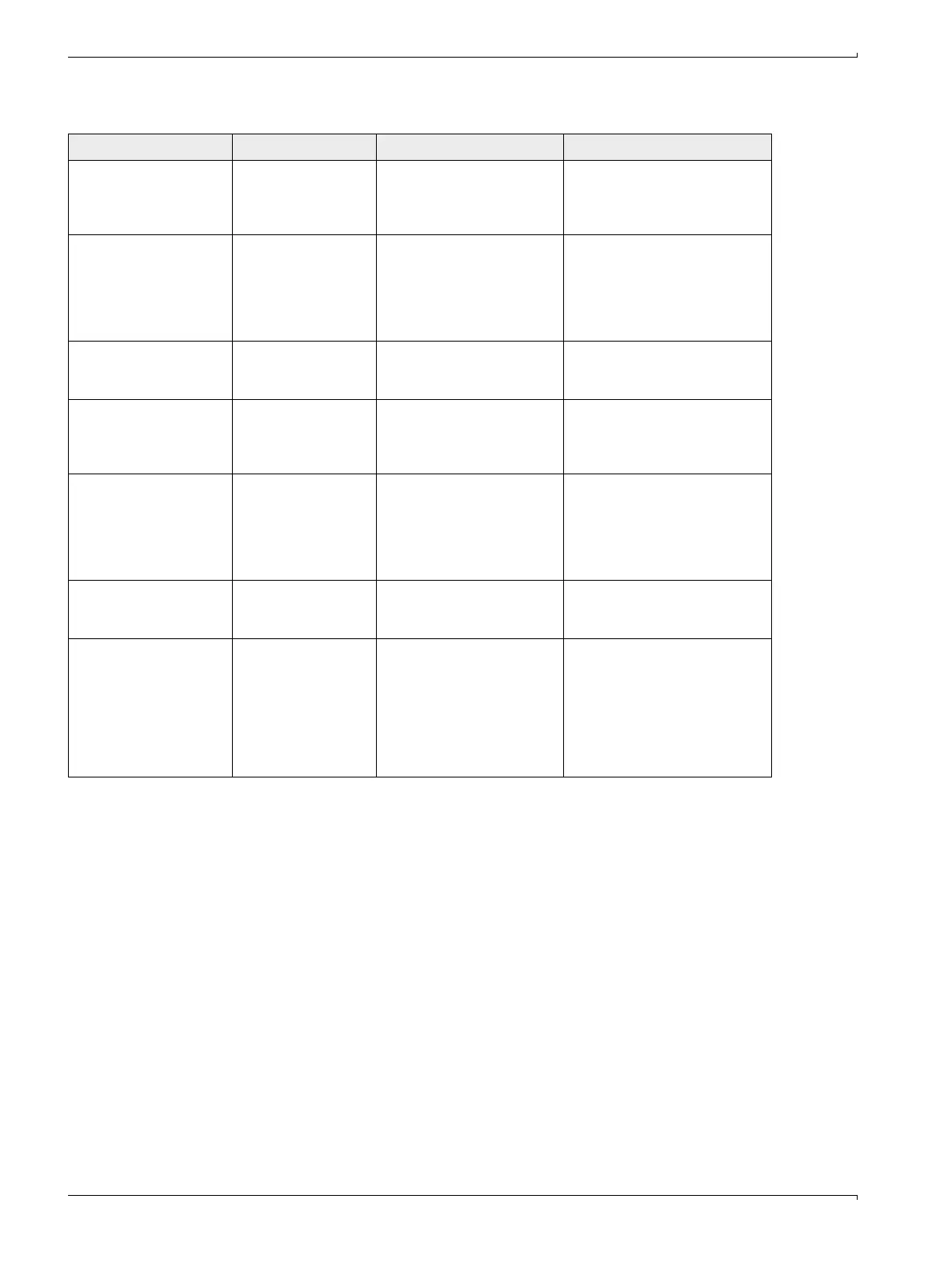

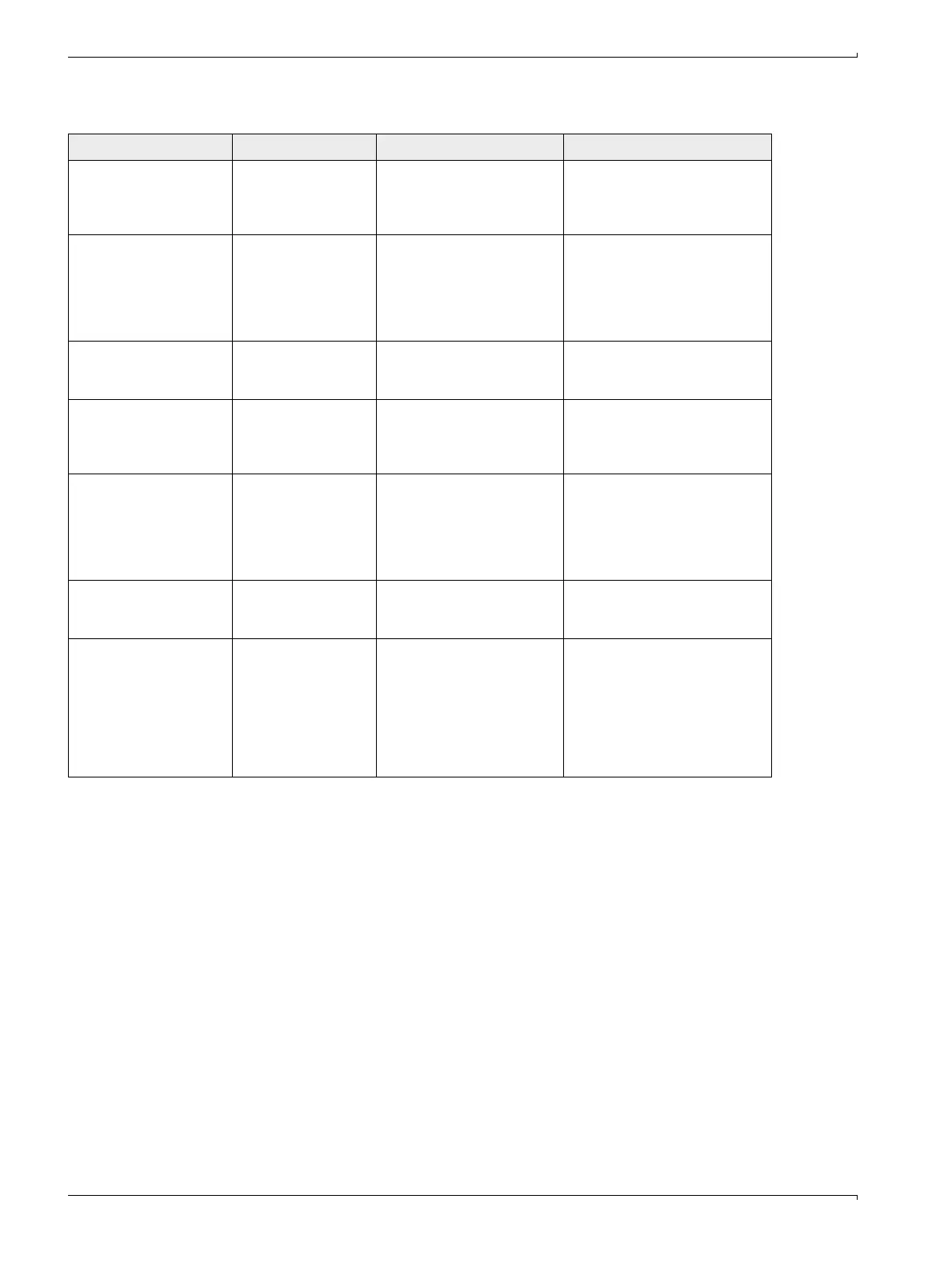

Message Significance Possible cause Action

LED monitor overflow Overdriving of the

monitor channel when

scaling

Incorrect alignment of the

optical axes of sender/receiver

unit and reflector

b

Check/correct alignment.

b

Repeat scaling.

Q1-4 overflow Group signal of

quadrant measurement

too high

● Measuring system not yet

scaled

● Changed alignment of opti-

cal axes

● Reduced active measuring

path

b

Scale measuring system.

b

Check/correct alignment.

b

Contact SICK service.

Set reference Scaling not possible Measurement or monitor signal

too low (contamination,

incorrect alignment)

b

Check/correct alignment.

b

Clean the optical surfaces (

→

p. 92, §5.2).

Overflow check point Measurement signal at

check point outside the

valid range

b

Repeat scaling.

b

Clean the optical surfaces (

→

p. 92, §5.2).

b

Contact SICK service.

Contamination (not for

DUSTHUNTER T50)

Current contamination

value is higher than the

permitted limit value (

→

p. 108, §7.1)

● Deposits on the optical sur-

faces

● Unclean purge air

b

Clean the optical surfaces (

→

p. 92, §5.2).

b

Check purge air filter and

replace, if required (

→

p. 97,

§5.3).

b

Contact SICK service.

LED span Deviation of control

value > ± 2%

● Deposits on the optical sur-

faces

● Vibrations

b

Clean the optical surfaces (

→

p. 92, §5.2).

b

Contact SICK service.

Reflector communication

(only for DUSTHUNTER

T200)

No connection between

sender/receiver unit

and reflector

● Connection cable not con-

nected or not connected cor-

rectly

● Defective connection cable

● Defectice reflector

● RS485 interface of the

sender/receiver unit defec-

tive

b

Check connection cable.

b

Contact SICK service.

Loading...

Loading...