GM35 Operating Instructions

Probe Model

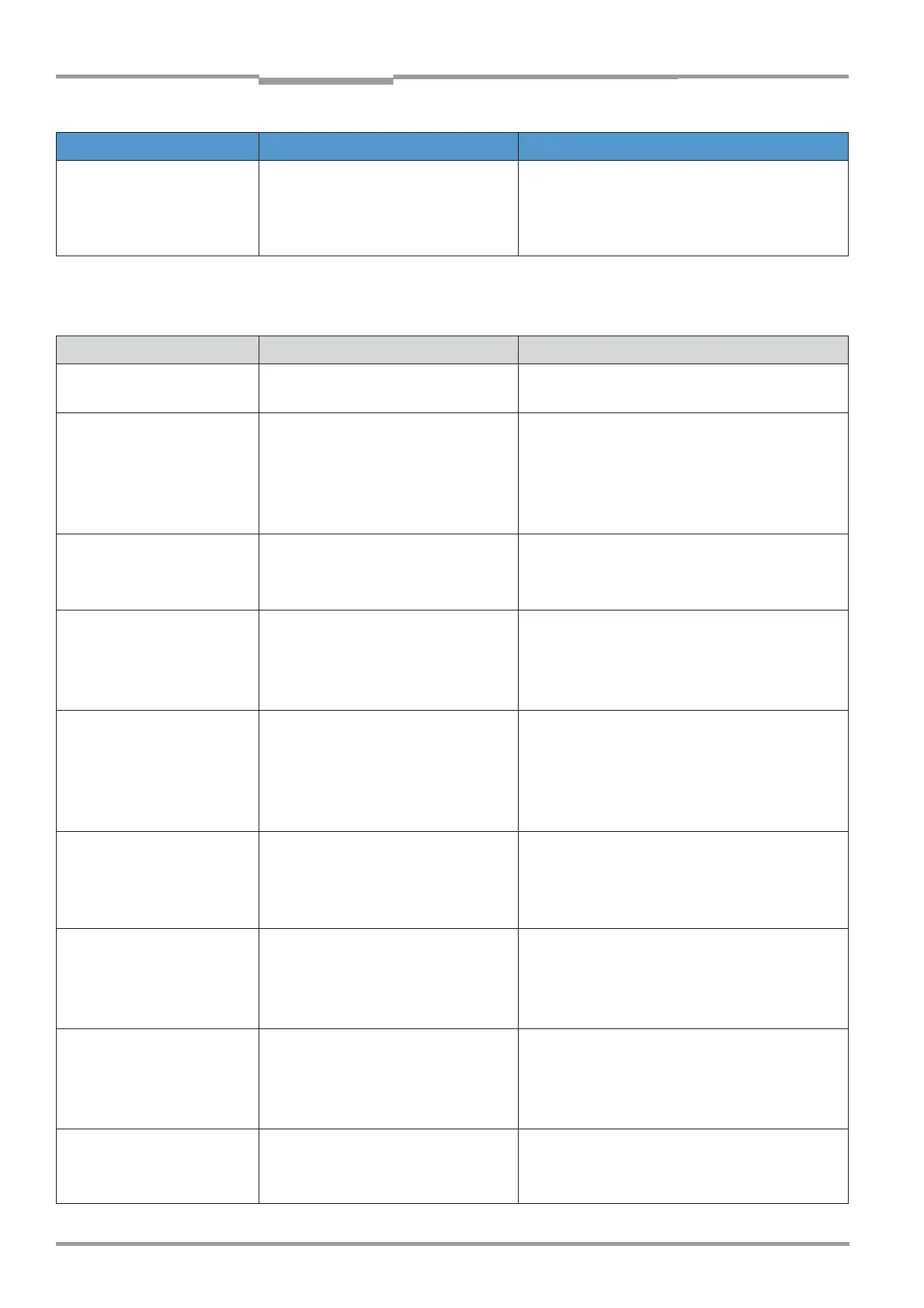

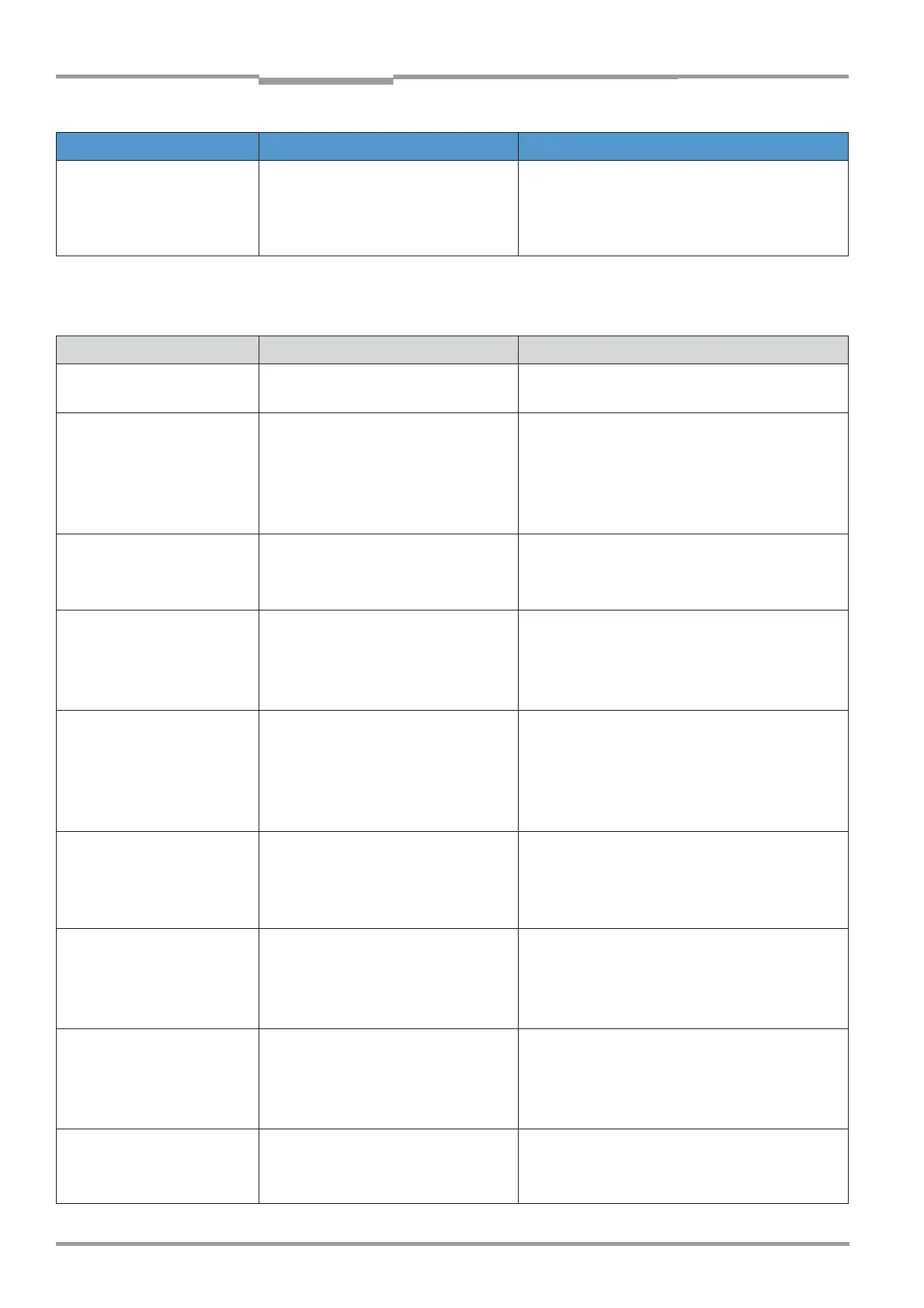

Troubleshooting

92 © SICK MAIHAK GmbH • Germany · All rights reserved 8009389/07-2006

9.3.3 Warning messages for the GM35 SR unit

ZERO com. CO

2

/H

2

O module not connected to

motor of zero-point reflector.

‡ Check whether the cable connection is secure.

Secure it if necessary.

‡ If fault cannot be corrected:

contact the Service department.

Error message Component/possible cause Remedy

Warning message Component/possible cause Remedy

Chopper freq. Chopper wheel frequency is outside

the tolerance

‡ Replace lamp module. Contact the Service de-

partment.

CO Low sig. • CO measurement channel contami-

nated

• Dust content too high

• IR source aged

‡ Check contamination; clean the optical

boundary surfaces (see page 68f)

‡ Check the optical alignment, page 72

‡ Replace IR source or measurement module; if

necessary contact service department

CO not ready • CO measurement is not ready

• Signal overridden

• Warm-up phase

‡ Wait approx. 30 min. until the operating tem-

perature has been reached

‡ Contact Service department if necessary

CO2 Reference Deviation of control vaues measure-

ment too high

‡ Carry out zero alignment, see page 54

‡ Carry out relevant maintenance, see chapter 8,

page 65

‡ Contact Service department if necessary

H2O Low sig. • H

2

O measurement channel conta-

minated

• Dust content too high

• IR source aged

‡ Check contamination; clean the optical

boundary surfaces (see page 68f)

‡ Check the optical alignment, page 72

‡ Replace IR source or measurement module; if

necessary contact service department

H2O not ready • CO

2

/H

2

O measurement not yet

ready

• Signal overridden

• Warm-up phase

‡ Wait approx. 30 min. until the operating tem-

perature has been reached

‡ Contact Service department if necessary

H2O Reference Deviation of control vaues measure-

ment too high

‡ Carry out zero alignment, see page 54

‡ Carry out relevant maintenance, see chapter 8,

page 65

‡ Contact Service department if necessary

HYGRO com No connection of CO

2

/H

2

O modules

with the humidity sensor

‡ Check correct cable connection and correct

plug-in connection; repair if necessary

‡ Switch to substitute value

‡ Contact Service department if necessary

HYGRO internal No communication to the onboard hu-

midity sensor

• Sensor defective/broken cable

‡ Check cable connection

‡ Remove sensor

Loading...

Loading...