GM35 Operating Instructions

Probe Model

Commissioning

54 © SICK MAIHAK GmbH • Germany · All rights reserved 8009389/07-2006

Checking on the Display of the Evaluation Unit

Before executing

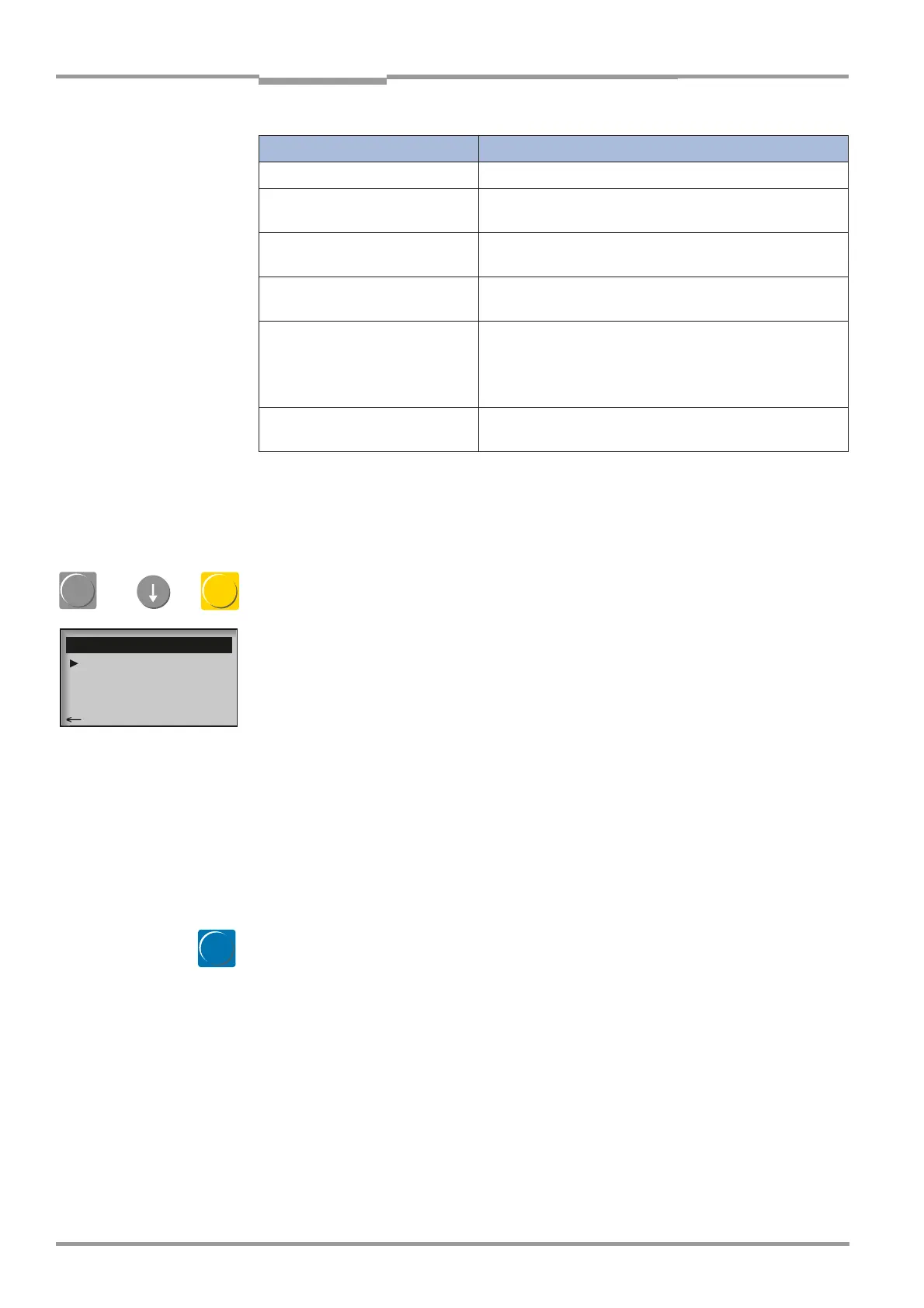

‡ Press diag button, select menu Adjust Probe and call it up with Enter;

with devices with automatic alignment control the optical reference position is started up.

‡ Check the indications on the display:

‡ Adjust the 2 screws at the device flange with 19 mm wrenches (see Fig. 39) until the in-

dications on the display show:

– the values for dx and dy are smaller or equal ±0,1

(dx…value for the horizontal position/adjustment)

(dy…value for the vertical position/adjustment).

The values A, B, C and D are device internal parameters. They should appear in the range

between 450…650.

‡ If the valid area for A to D cannot be attained also after repeated adjusting of the screws,

and are the values for dx and dy ≤ 0.1 check the warning and error messages in the di-

agnosis mode (see „Menu structure“ on page 72) and perform the necessary mainte-

nance and remedy procedures. Refer to chapter „Integrated monitoring and diagnosis

system“ on page 102 and following.

‡ Change to the measuring mode:

‡ Press the meas button.

6.4.4 Zero-point adjustment

After the GM35 SR unit, if necessary the probe and the Evaluation Unit have been connect-

ed to the power supply, a warm-up time of approx. 2.5–5 hours (depending on the ambient

conditions) is required before the zero-point adjustment can be carried out.

‡ If you are using a GPP measuring probe, make sure that the power supply is connected

and that the optical boundary surfaces on the measuring probe are heated.

‡ Wait approx. 2.5 hours after the SR unit has been connected to the power supply. Simi-

larly, if you are using a GPP measuring probe, wait until this warm-up time has elapsed.

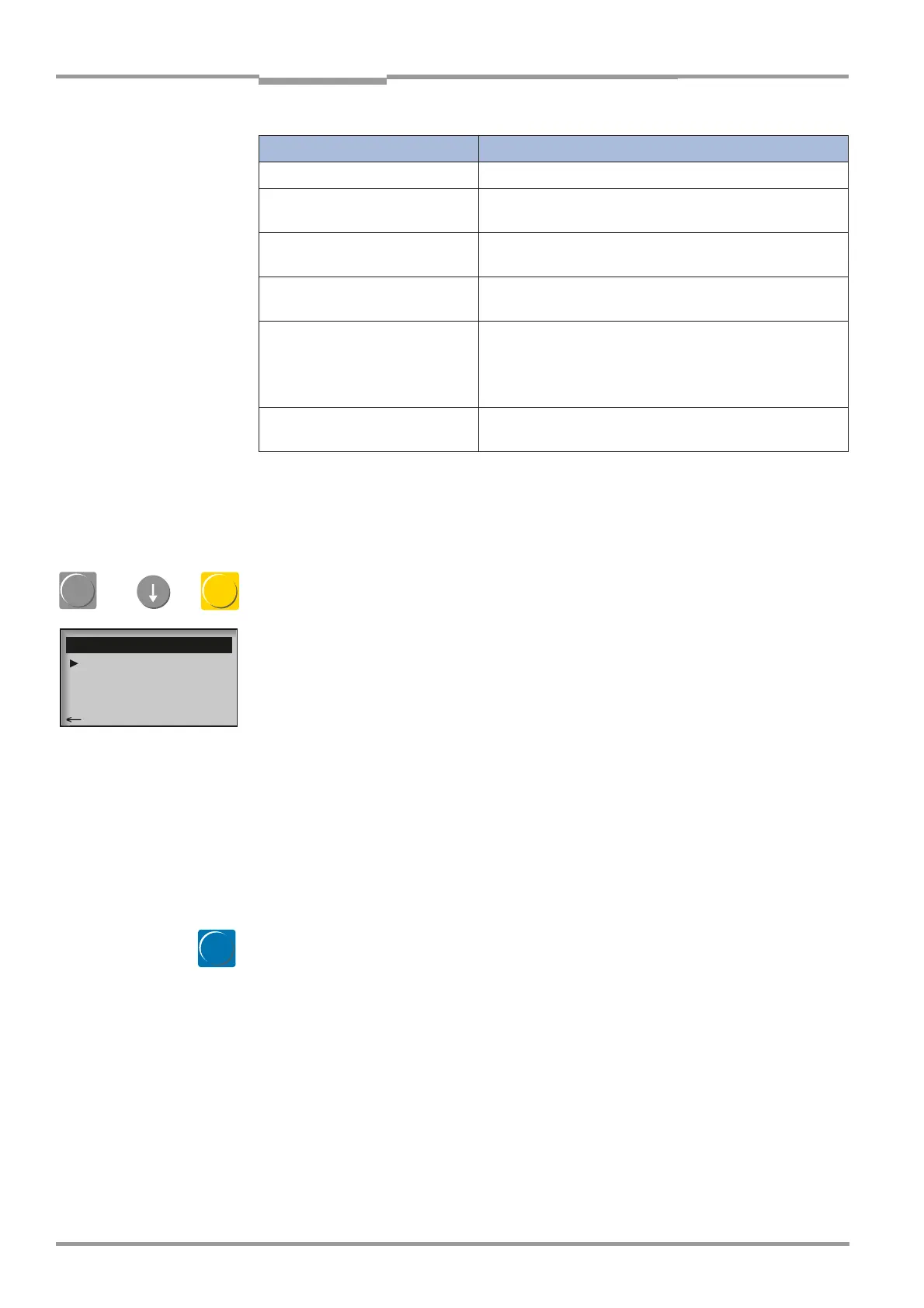

Indication in the LED matrix

Meaning

Center LED flashes Analyzer ideal aligned

One LED of the inner square

flashes

Alignment within the half tolerance

One LED of the outer square

flashes

Alignment on the tolerance limits; must to be corrected

One LED of the outer square

blinks

Alignment out of tolerance limits; must be corrected

Center LED blinks No signal; reflector is not "seen" from the SR unit,

because for example the alignment is way out of the

limits, no probe is installed or reflector is strongly con-

taminated.

Lauflicht der mittleren LED-

Reihe

Für die Dauer von Aufwärmphase, Kontrollzyklus, Refe-

renzzyklus ist keine Ausrichtung möglich.

Meaning of the LED matrix of the sight

diag

Enter

A: 467 B: 429

C: 425 D: 438

dx: -0.017

dy: 0.021

Adjust Probe

back save: Enter

meas

Loading...

Loading...