Operating Instructions GM35

Probe Model

Troubleshooting

8009389/07-2006 © SICK MAIHAK GmbH • Germany · All rights reserved 83

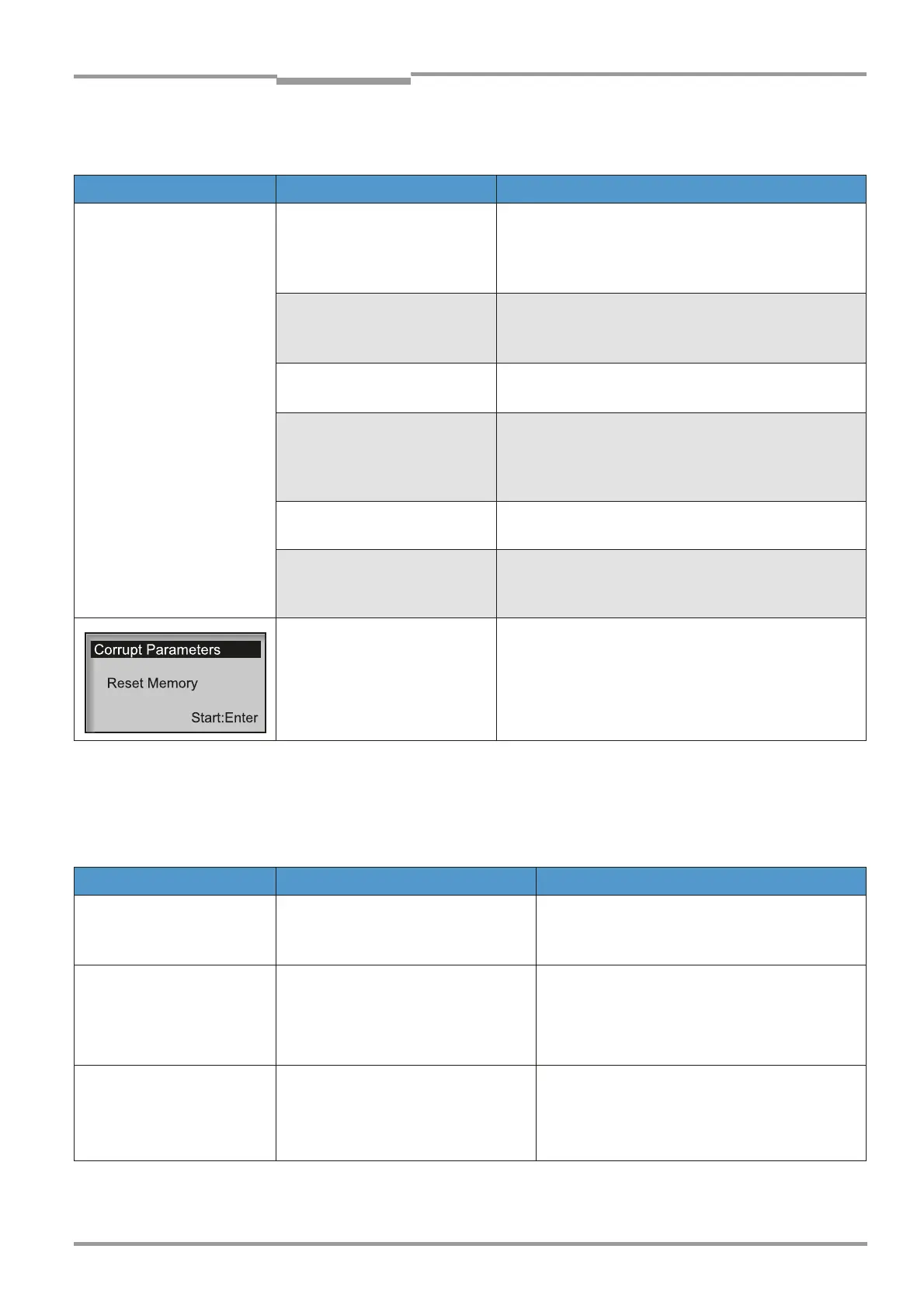

9.3.1 Troubleshooting the evaluation unit

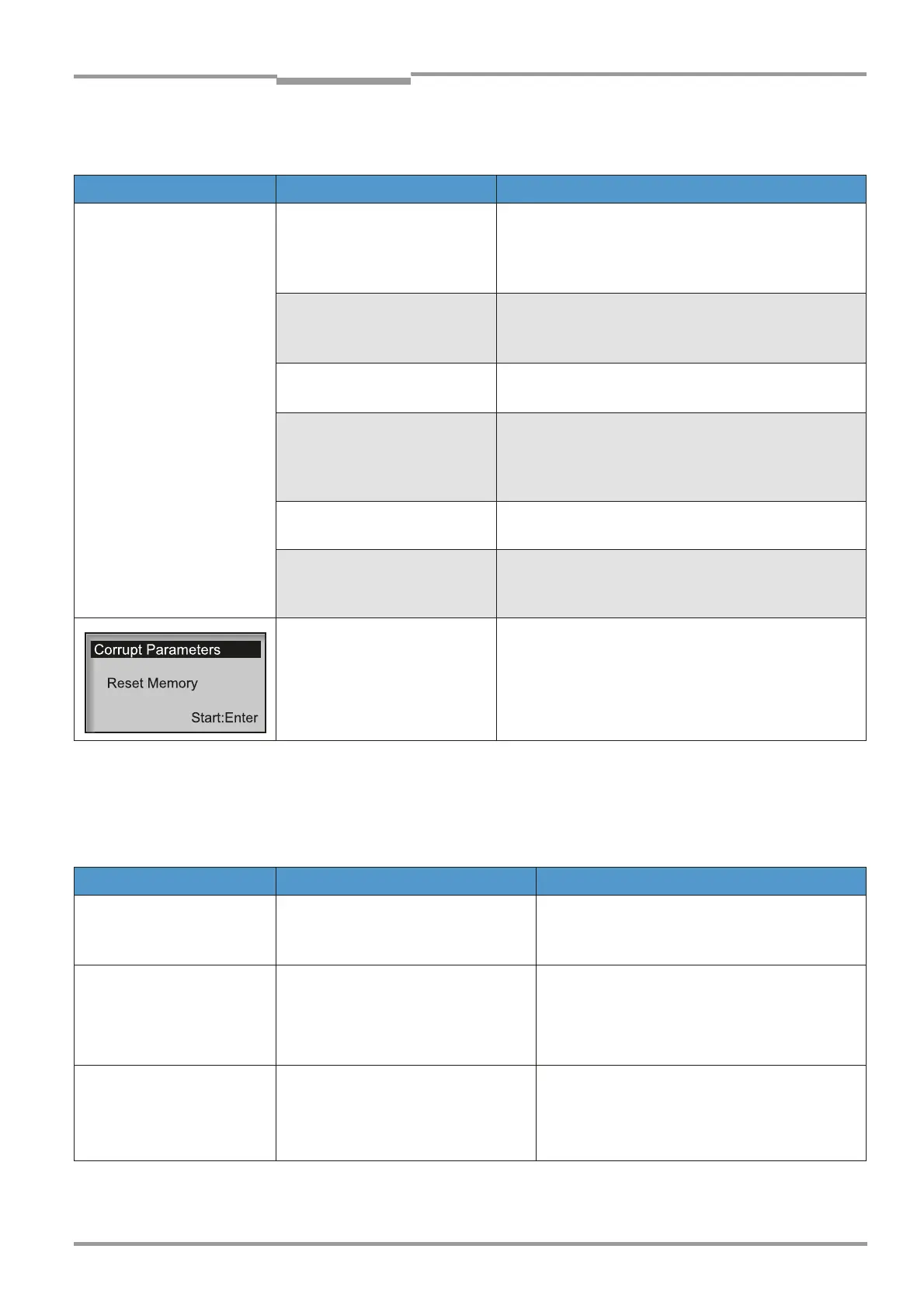

9.3.2 Error messages for the GM35 SR unit

The following error messages, which can be displayed on the evaluation unit, refer to the

GM35 SR unit and the purge air attachments.

Error description/message Component/possible cause Remedy

Evaluation unit not respond-

ing

Evaluation unit:

• Power supply to evaluation unit

defective

‡ Check power supply to all system components:

– If necessary, connect on-site power supply

– If necessary, check/reconnect the terminals on the

system components

Evaluation unit:

• Incorrect operating voltage

‡ Check the operating voltage set on the evaluation

unit:

– If necessary, change setting

Evaluation unit:

• Fuse defective

‡ Check the fuse in the evaluation unit:

– If necessary, change fuse

Evaluation unit:

• No defect localized

‡ Disconnect all system components from the power

supply and reconnect them one after the other

– Check the CAN bus cable from the evaluation unit to the

SR unit or terminal box

Evaluation unit:

• Error occurs again

‡ Replace the component last connected; contact the

Service department

Evaluation unit:

• 24V/5V supply defective

‡ Check 24V/5V supply,

Replace evaluation unit or electronic board module;

contact Service department

Evaluation unit:

• Inconsistent data detected in

parameter memory

‡ Press Enter to restart the system; the default

parameter settings are then active;

‡ If necessary, reconfigure the parameters

‡ If the same error message occurs again, replace the

evaluation unit and contact the Service department

Error message Component/possible cause Remedy

Air purge low SLV The volumetric flow undershoots the

set threshold.

‡ Check the purge air supply (fan, hoses). If nec-

essary, replace the filter on the purge air fan

(see chapter 8.3.2, page 70.

CO Ampl. max CO instrument amplifier is above the

control range

‡ Check alignment (see page 72).

‡ Clean optical boundary surface (see page 47/

page 68).

‡ Contact the Service department.

CO com. CO

2

/H

2

O module not connected to

CO module

‡ Check whether the cable connection is secure.

Secure/repair it inside the GM35 if necessary.

‡ If fault cannot be corrected: contact Service

department.

Loading...

Loading...