Maintenance

GMS800 · Operating Instructions · 8013025 V1.2 · © SICK MAIHAK GmbH 55

Subject to change without notice

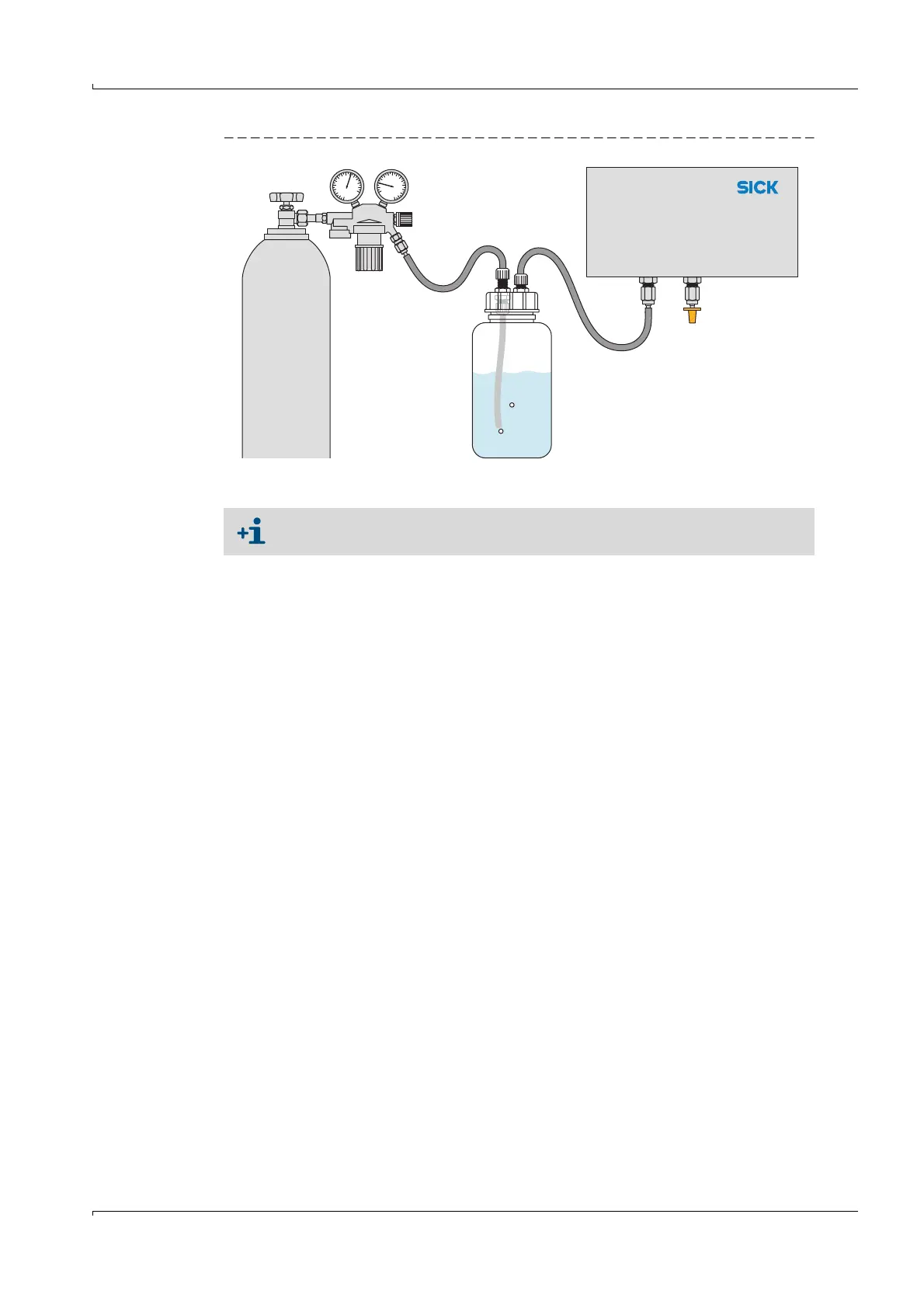

Fig. 10 Simple test method for leak tightness check (example)

Test procedure

1 Put the gas analyzer out of operation. Separate the gas inlet and outlet of the gas ana-

lyzer from the installation (when fitted).

2 Connect the gas analyzer gas inlet to the washing bottle gas outlet.

3 Close the gas analyzer gas outlet off gas-tight, e.g. with a sealing plug.

4 Also close off all the other internal gas path connections (as available) in the same man-

ner.

5 Check: The valve on the pressure reducer gas outlet must be closed off. Now open the

main valve of the compressed gas cylinder.

6 Adjust the pressure reducer so that the output pressure (secondary pressure) is

150 kPa (1.5 bar).

7 Connect the pressure reducer gas outlet to the washing bottle gas inlet.

8 Open the pressure reducer valve slowly (avoid sudden pressure increase).

9 Wait until the pressure ratio is constant (several seconds).

10 Observe the washing bottle: Count the number of air bubbles rising for 1 minute.

The gas path is classified as tight when less than 60 air bubbles rise per minute.

11 To terminate the test procedure:

– Close off the valve on the pressure reducer gas outlet.

– To release the gas pressure: Carefully loosen the connection hose on the washing

bottle gas outlet.

– Reconnect the gas connection on the gas analyzer as for operating mode - pay

careful attention to gas leak tightness.

Gas analyzer

When the gas analyzer has several separate internal gas paths:

b

Perform this procedure individually for each gas path.

Loading...

Loading...