8014868/YEF7/2014-09-02 • © SICK AG • Subject to change without notice 23

Operating instructions Distance sensors Dx35

Mounting

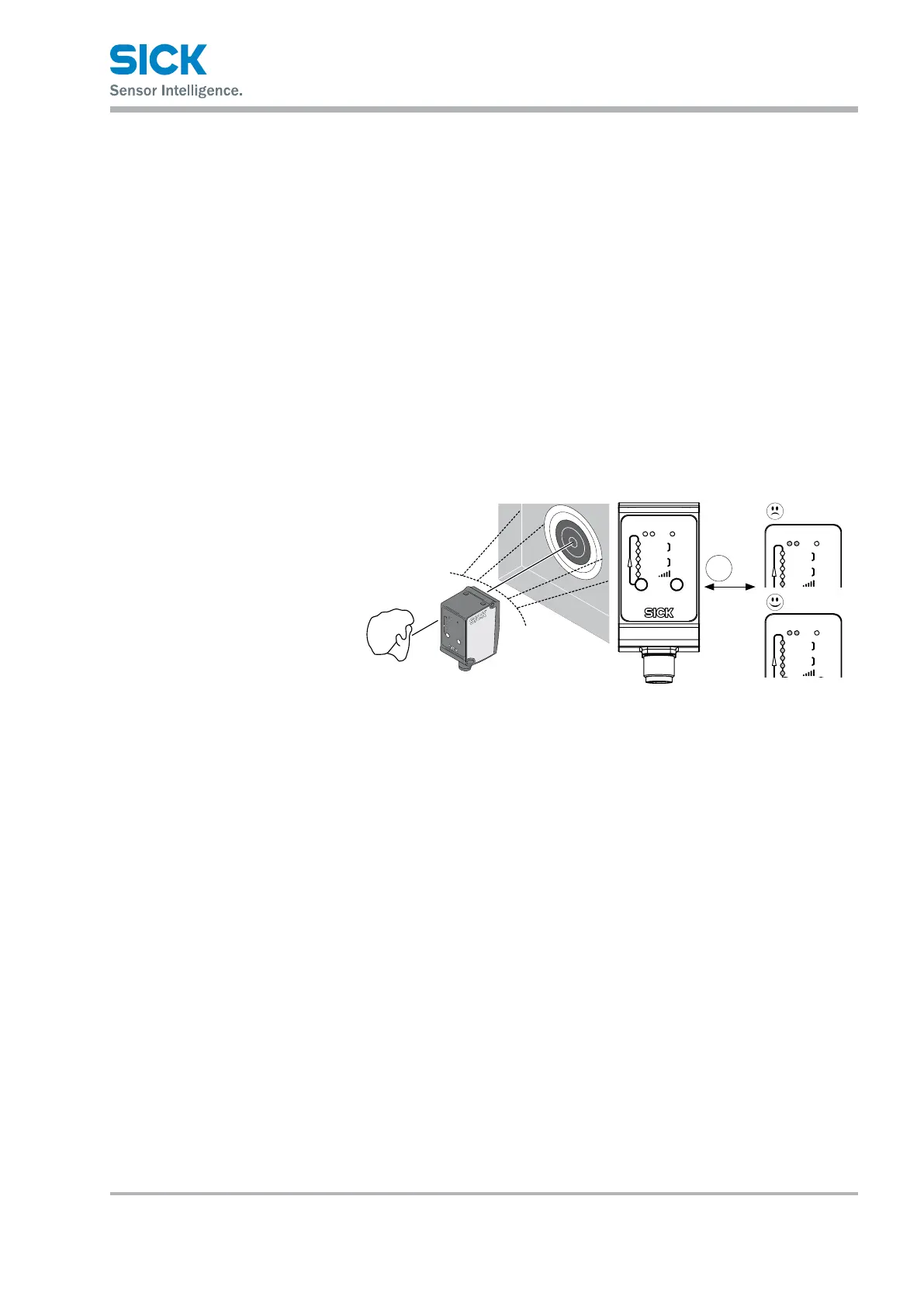

5. Perform ne adjustment. Align the distance sensor such that

the highest possible alignment quality is indicated. The alignment

quality is indicated as follows:

• using the vertically arranged LEDs Q1 near to slow … fast: The

greater the number of LEDs that light up, the better the alignment

quality.

• using the LEDs Q1 and Q2: The faster both LEDs ash, the better

the alignment quality. Slow ashing at approx. 1 Hz corresponds to

poor alignment quality (no reective tape). Rapid ashing at approx.

15 Hz corresponds to high alignment quality (highest reective level).

6. In order to leave alignment mode, either press and hold the set

pushbutton longer than 5 seconds or wait 5 minutes without pressing

the pushbuttons.

7. Remove the small reective tape used for alignment from the object.

8. For DL35 and DR35 models, attach a large reective tape for

performing the measurement.

Q1 Q2

Q1 near

Q1 far

Q2 near

Q2 far

ObSB

select

set

run

ObSB

fastslow

set

>5s

Q1 Q2

Q1 near

Q1 far

Q2 near

Q2 far

ObSB

run

ObSB

fastslow

Q1 Q2

Q1 near

Q1 far

Q2 near

Q2 far

ObSB

run

ObSB

fastslow

1 Hz

15 Hz

Fig. 6: Aligning infrared light models, entering alignment mode

Loading...

Loading...