Maintenance

GM32 · Technical information · 8011923 · V1.4 · © SICK AG 75

Subject to change without notice

13 Fit pressure reducer on the test gas cylinder.

14 Make a connection between fitting and filter box (test gas).

15 Set the valve to select the appropriate chamber or combination.

Set the “Measuring / Purging” valve to “Purging” to fill the chamber quickly.

16 When the measured value shown in SOPAS ET is constant, switch the “Measuring /

Purging” to “Measuring”.

The overpressure is reduced.

Wait for a constant measured value and note the display.

17 Repeat test gas application with all possible chambers and combinations.

18 Close the cylinder valve. Switch valve “Measuring / Purging” to “Purging”.

Set all chambers to “Test gas”.

When the pressure in the pressure reducer has dropped to zero, switch all chamber

valves to “Zero gas”.

19 Dismount the pressure reducer from the test gas cylinder.

To carry out another measurement with a different test gas:

Start again at

13.

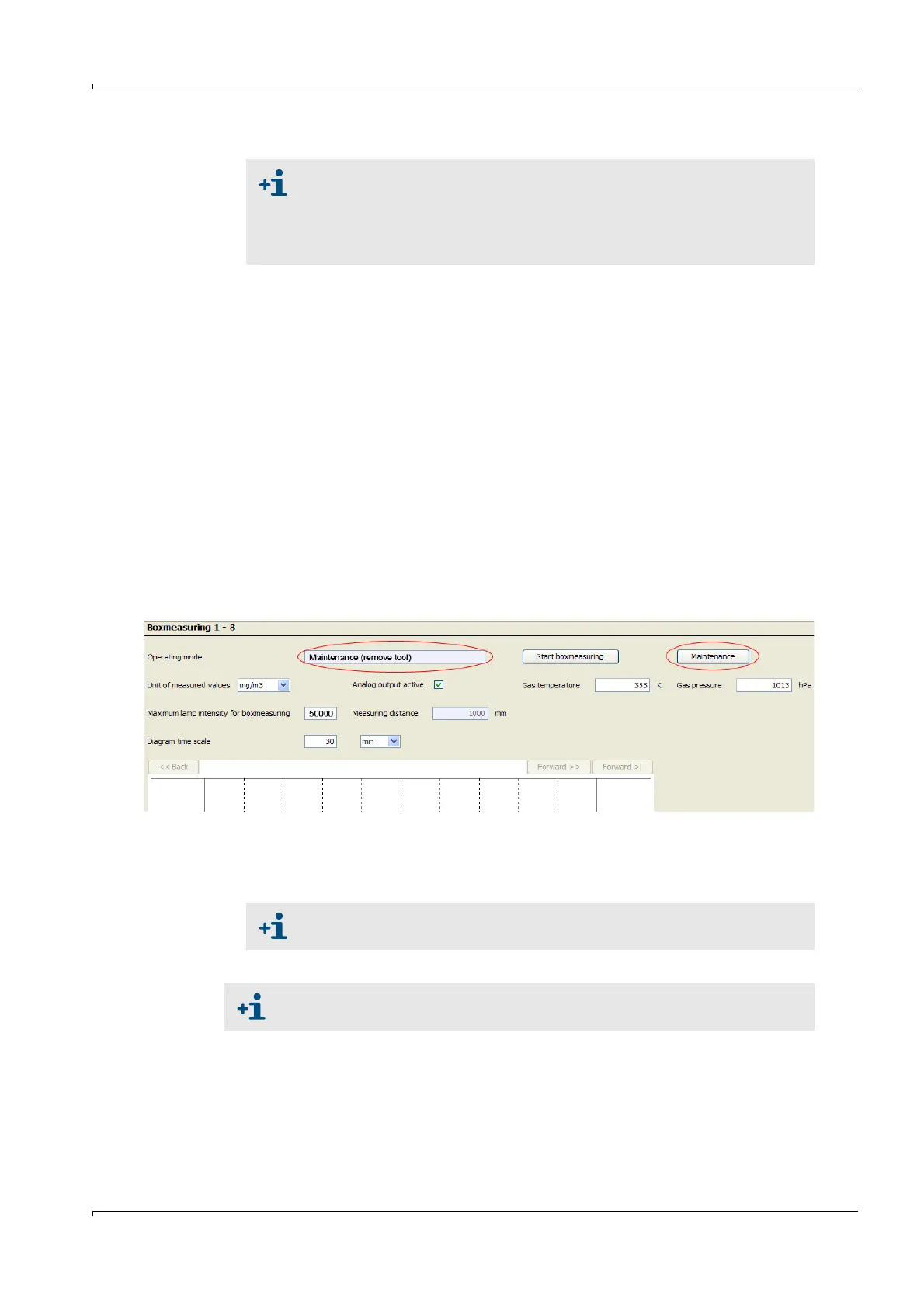

20 After measurement has completed, click “Maintenance”. The message “Maintenance

(remove tool)” appears under “Operating mode”

21 Dismount the filter box from the GM32.

22 Fit the GM32 back onto the measuring point.

23 SOPAS ET menu Maintenance Operating mode switch.

Click “Measuring” to switch the GM32 to operating mode “Measuring”.

The check is completed with operating mode ’’Measuring’’.

Open the gas outlet of the pressure reducer and cylinder valve for a

short time to flush the gas fitting.

Set the pressure reducer to a value between 0.5 and 1 bar.

Close the gas outlet and make a connection to the filter box.

Open the gas outlet again afterwards.

The GM32 triggers a reference cycle.

The filter box scaling is overwritten automatically.

Loading...

Loading...