Circuit Description UMSITRPDS3-1

November 2005

8-4

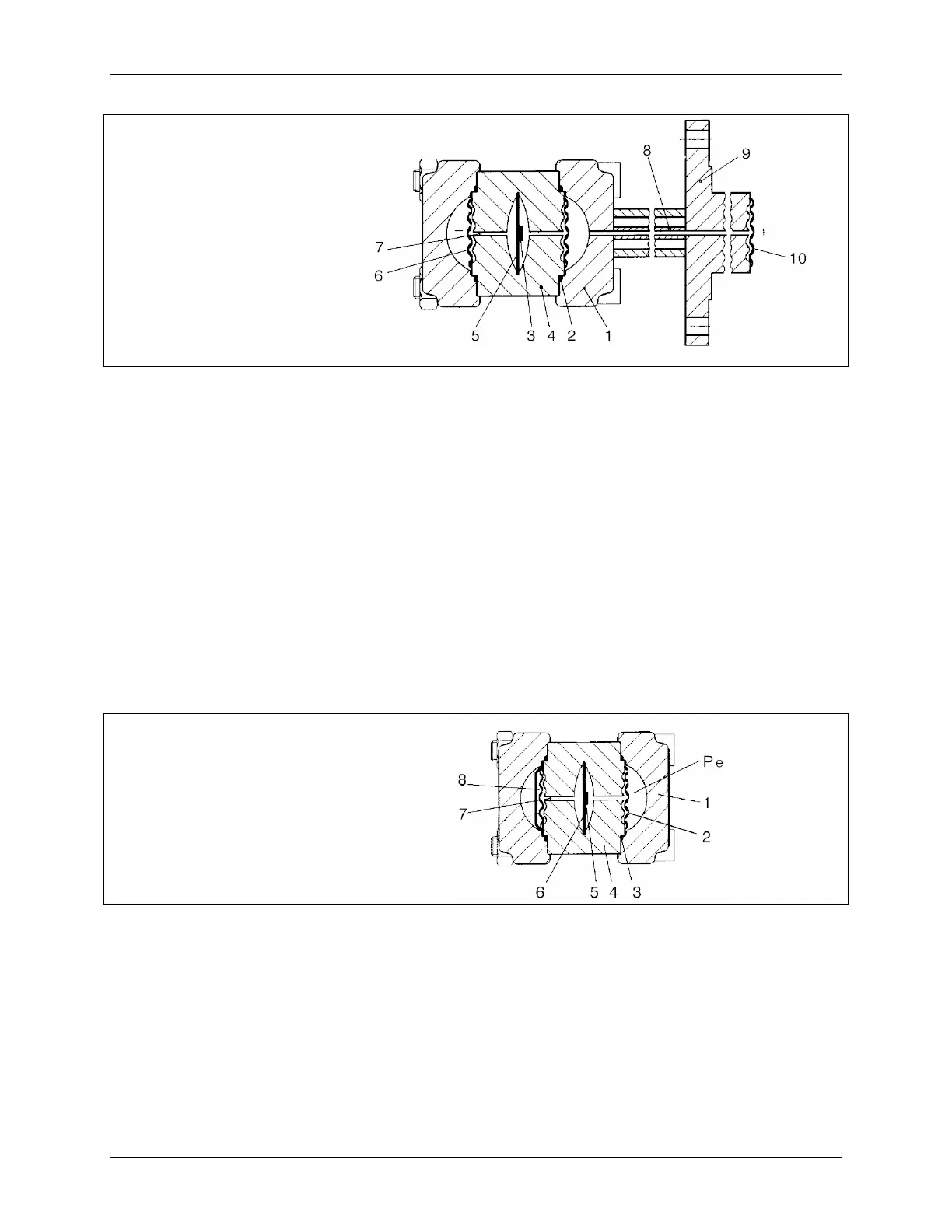

1

2

3

4

5

6

7

8

9

10

Process flange (qty. 2)

O-ring (qty. 2)

Silicon pressure sensor

Measuring cell body

Overload diaphragm

Seal diaphragm at the

measuring cell (qty. 2)

Fill fluid

Capillary tube with fill

fluid

Mounting flange with

capillary tube

Seal diaphragm at the

mounting flange

FIGURE 8-4 Flanged Level Measuring Cell

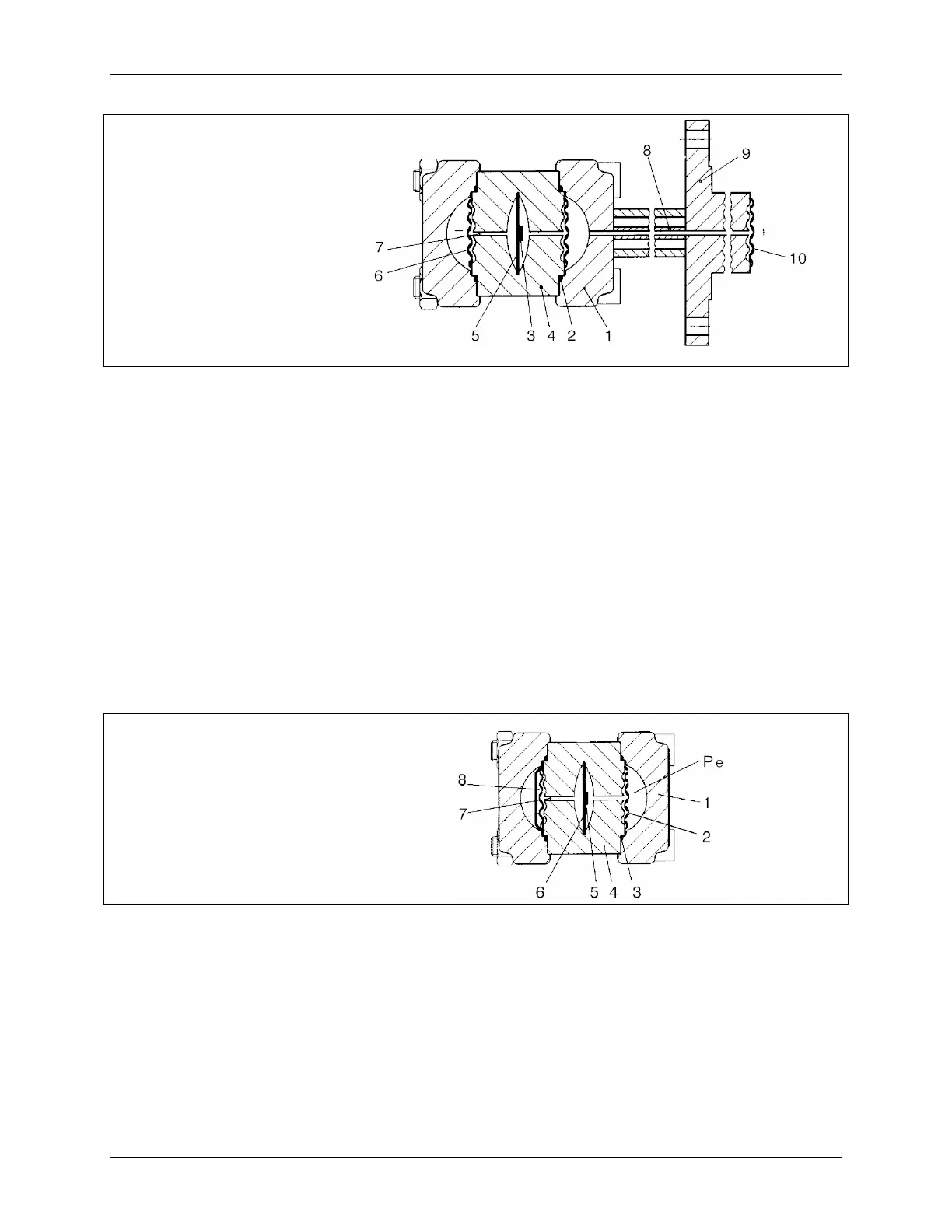

8.5 ABSOLUTE PRESSURE (DIFFERENTIAL CONSTRUCTION)

Absolute pressure p

e

is transferred via the seal diaphragm (2) and the fill fluid (7) to the silicon pressure

sensor (5). The pressure difference between the input pressure (p

e

) and the reference pressure (8) on the

low pressure side of the measuring cell flexes the measuring diaphragm. Four piezo-resistors in a bridge

circuit grown on the measuring diaphragm change their resistances in response to the change in applied

pressure. The change in resistance causes a bridge output voltage change that is proportional to the

absolute pressure.

If measuring limits are exceeded, the overload diaphragm (5) will deflect until the seal diaphragm comes

into contact with the body of the measuring cell (4) protecting the silicon pressure sensor (5) against the

overload.

1

2

3

4

5

6

7

8

p

e

Process flange (qty. 2)

Seal diaphragm at the

measuring cell (qty. 2)

O-ring (qty. 2)

Measuring cell body

Silicon pressure sensor

Overload diaphragm

Fill fluid

Reference pressure

Input variable pressure

FIGURE 8-5 Absolute Pressure Measuring Cell, Differential Construction

8.6 ABSOLUTE PRESSURE (GAUGE CONSTRUCTION)

Pressure p

e

is applied via the seal diaphragm (3) and full fluid (4) to the absolute pressure sensor (5). See

Figure 8-6. This flexes the measuring diaphragm on which four piezo-resistors in a bridge circuit have

been grown. Bridge resistance will vary with the applied pressure to generate a bridge output voltage that

is proportional to the input pressure.

Loading...

Loading...