UMSITRAPDS3-1 Model Designations and Specifications

November 2005

9-17

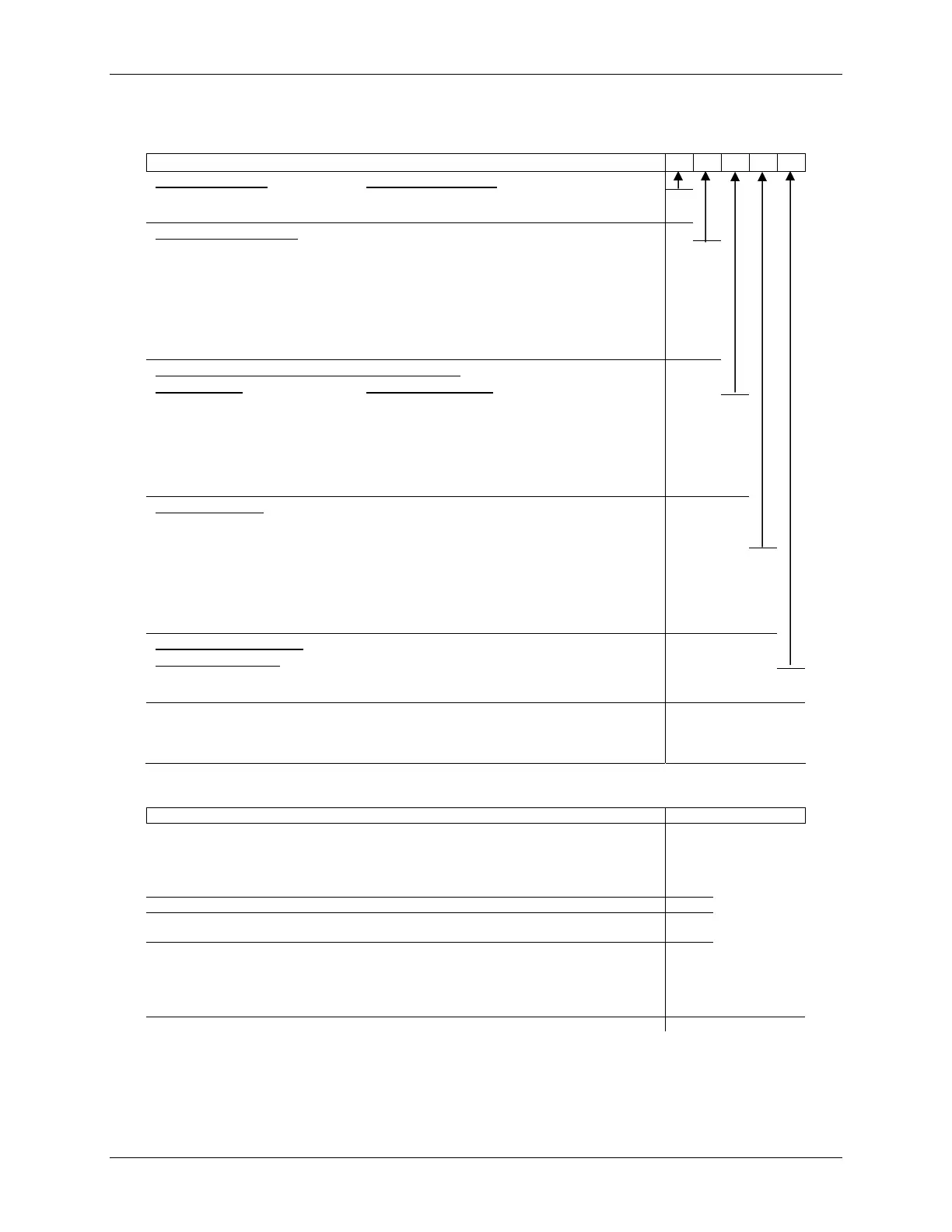

TABLE 9-10 Measuring Cells for Pressure and Flow, Differential Const., Service Parts

DS III and DS III PA series, differential construction, 7MF4994-

Measuring cell filling Measuring cell cleaning

Silicon oil Normal

1

Inert Grease-free

3

Nominal measuring range

PN 460 psi, static span 0.4 To 8 inH

2

O

1)

B

PN 2320 psi, static span 0.4 To 24 inH

2

O

C

1 To 100 inH

2

O

D

2.4 To 240 inH

2

O

E

6.4 To 640 inH

2

O

F

20 To 2000 inH

2

O

G

4.3 To 435 psi

H

Wetted parts materials (stainless steel process flanges)

Seal diaphragm Parts of measuring cell

Stainless steel Stainless steel

A

Hastelloy Stainless steel

B

Hastelloy Hastelloy

C

Tantalum

2)

Tantalum

E

Monel

2)

Monel

H

Gold

2) 3)

Gold

L

Process connection

Female thread 1/4-18 NPT with flange connection to DIN 19213 with:

Sealing screw opposite process connection

- Mounting thread M10

0

- Mounting thread 7/16-20 UNF

2

Sealing screw on side of process flange

- Mounting thread M10

4)

4

- Mounting thread 7/16-20 UNF

4)

6

Non-wetted parts materials

Process flange screws

Steel

0

Stainless steel

2

1)

Not for remote seal connection

2)

Only with span D, F, G, or H

3)

Only with stainless steel process flange screws

4)

Not with K01 or K02

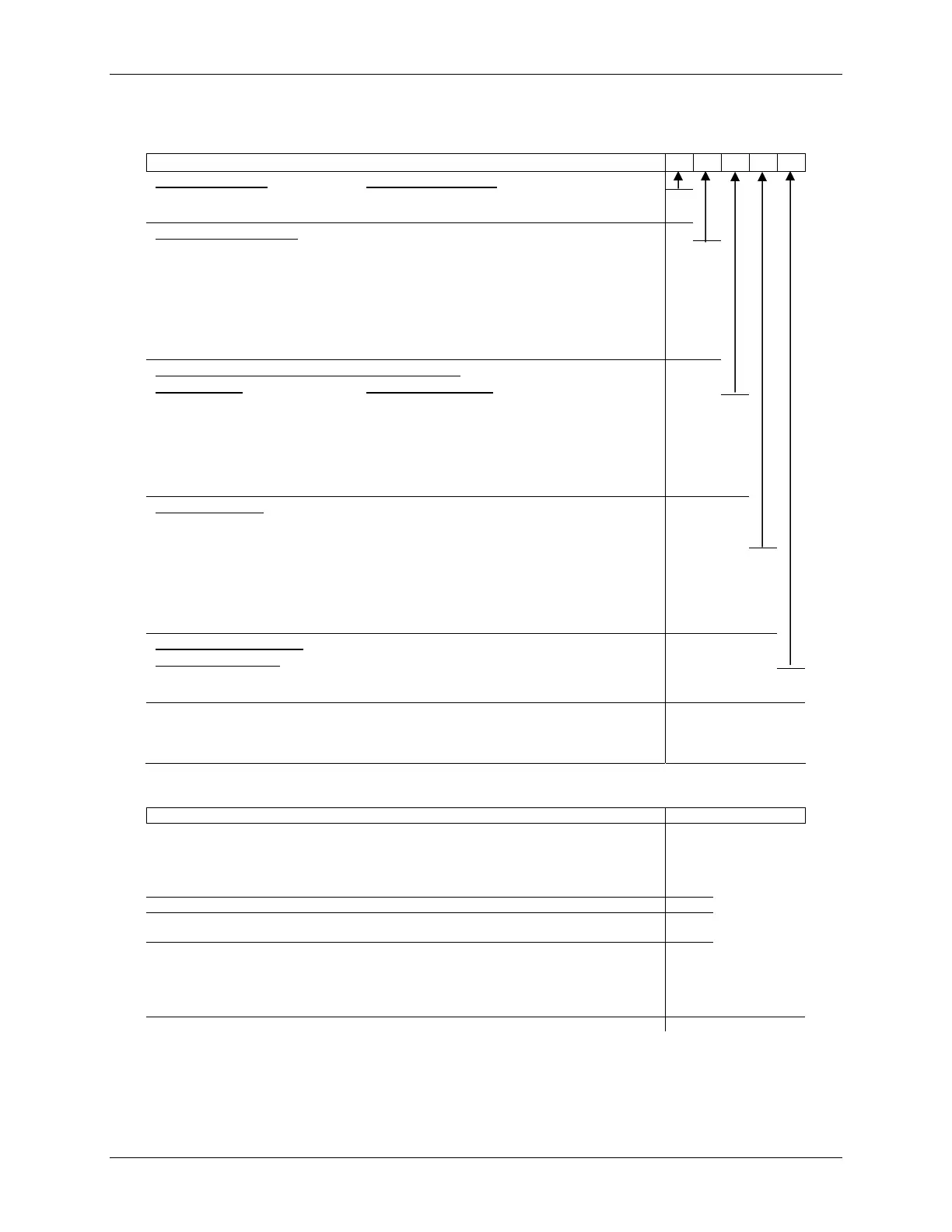

Other versions

Add "Z" to the order number and the specify order code 7MF4994-............- Z

Process flange O-ring (instead of FPM (Viton)) made of:

- PTFE (Teflon)

A20

- FEP (with silicone core, approved for foodstuffs

A21

- FFPM (Kalrez)

A22

- NBR (Buna N)

A23

Remote seals; not with K01, K02 or K04

D20

Vent on side for gas measurements

H02

Process flanges of stainless steel for vertical differential lines; not with K01, K02 or K04

H03

Process flanges:

- without process flanges

K00

- Hastelloy flanges

K01

- Monel flanges

K02

- Stainless steel, with PVDF insert, flanges

K04

Loading...

Loading...