Function and design

18

Building Technologies A6V10265083_a_en_--

Fire Safety & Security Products 03.2010

5.1.6 Control line extension card

Summery

The optional control line extension card features 4 monitored control outputs (con-

trol line 3 - 6). The following devices can be connected to the control outputs:

– Alarm devices like horns or flashlights

– Remote fire control installations

– RT devices

Functionality

The control outputs of control lines 3 – 6 have basically the same features as the

control outputs of control lines 1 and 2. For the control lines 3 - 6, attention should

be paid to the following:

– It is defined in programming step 5 when and how the control outputs are acti-

vated. In addition, each control output (control line 3 – 6) has a control

input (A – D). Input A is related with output 3 etc. An AND combination between

the setting in programming step 5 and the control input is enabled with a

Jumper, e.g. control output 3 shall only be activated in case of alarm 2 AND

driver output of zone 4 is active.

– Only control line 6 can be activated in case of a RT fault (see Step 5, activation

mode of control lines, option 14). If so, the Jumpers have to be set accordingly

(see table below).

– A LED is assigned to each control output. If the LED flashes, the corresponding

control output has either a line break or a short line.

Connection

– The board will be connected via the enclosed ribbon cable on the connector

CN10 to the main board.

– For power supply, a separate line has to run from the power supply card (termi-

nals on the right side of the card) to the control line extension card.

– If a control line is not used, it to has to be terminated with an EOL (FCE1002; in-

cluded in delivery).

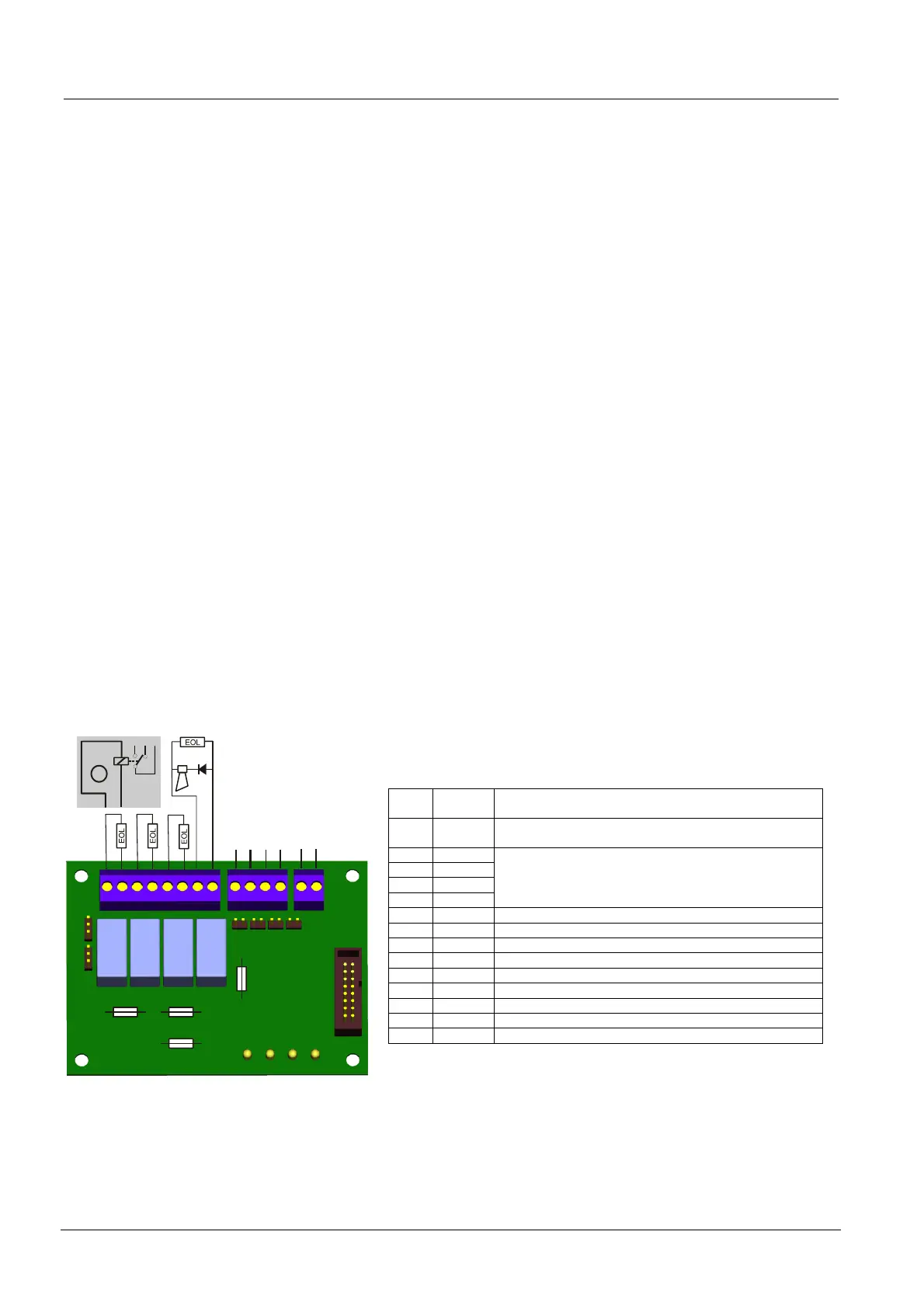

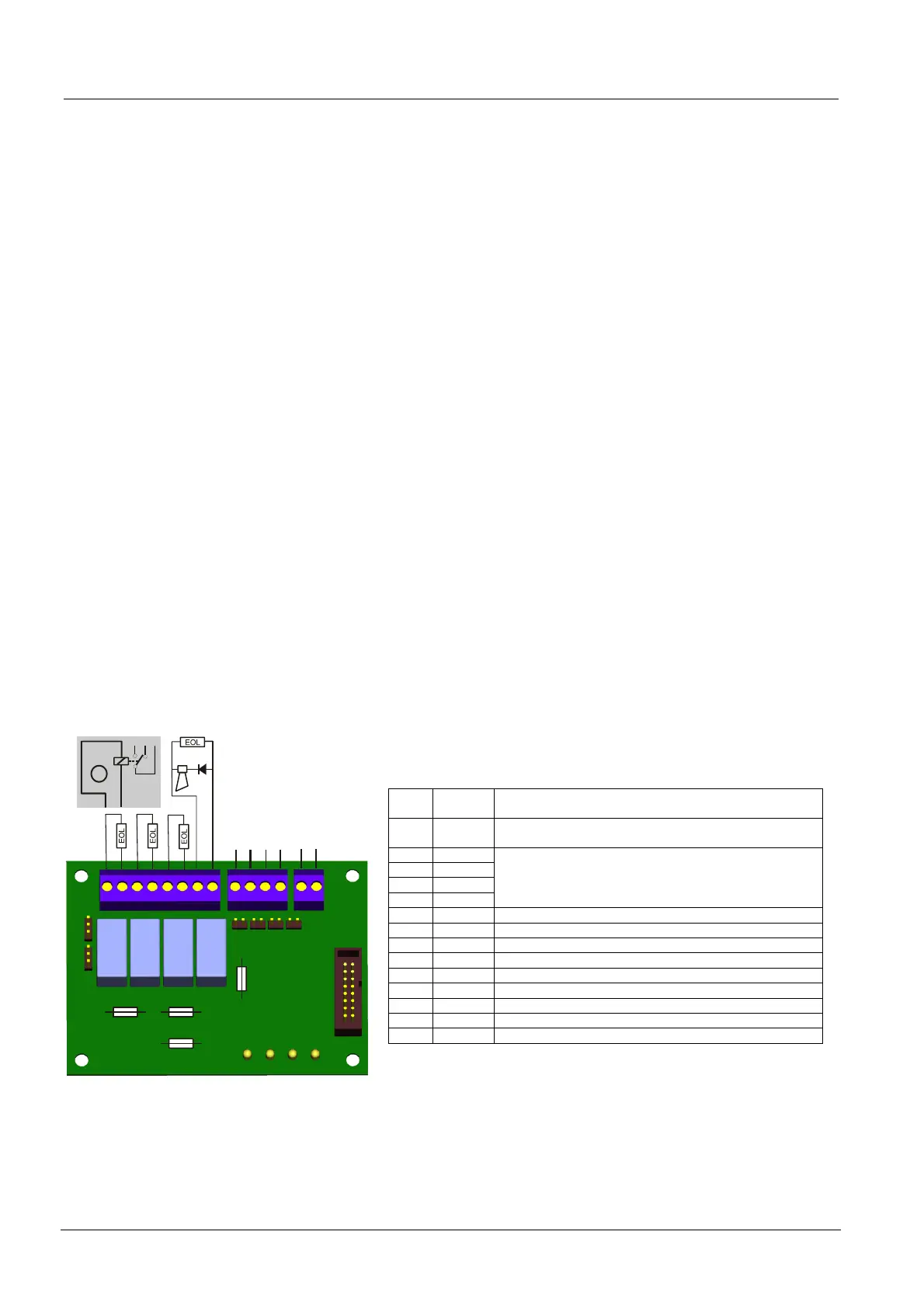

The allocation of connection can be seen in the following board illustration.

Ref. Control

line

Setting / Function

PU1,

PU2

6

Pos. top = if option 14 progr. step 5 is selected

Pos. bottom = if option 1-13 in progr. step 5 is selected

PU3 5

PU4 6

PU5 4

PU6 3

OFF = zone-specific activation (control input used)

ON = common activation (control input not used)

DL1 3 LED flashing upon break or short

DL2 4 LED flashing upon break or short

DL3 5 LED flashing upon break or short

DL4 6 LED flashing upon break or short

CN1 Connector for flat cable to main board

F1 3 500 mAT Control line 3

F2 4 500 mAT Control line 4

F3 5 500 mAT Control line 5

F4 6 500 mAT Control line 6

PU4

PU3

PU5

PU6

PU2

PU1

DL1

DL2

DL3

DL4

A

B

C

D

+

-

+

-

+

-

+

-

+

-

CN1

1N4007

3

6

control input for line 6

control input for line 5

control input for line 4

control input for line 3

For zone-specific

activation only

input 24V supply

5

4

6

A

top

F1

F3

F4 F2

(A) Special Application: Line 6 used as remote control of state RT-fault

- Function: Line is activated in normal operating state and inactive in state system fault and on power off (FC10)

- Only possible with line 6

- Program option 14 in programming step 5

- Set jumper PU1 and PU2 on FCA1003 to position top

- Connect load between 350 … 2500 Ω (without EOL)

Loading...

Loading...