Electrical connection

8.3 System integration

1FW3 complete torque motors

306 Configuration Manual, 08/2020, A5E46027705B AA

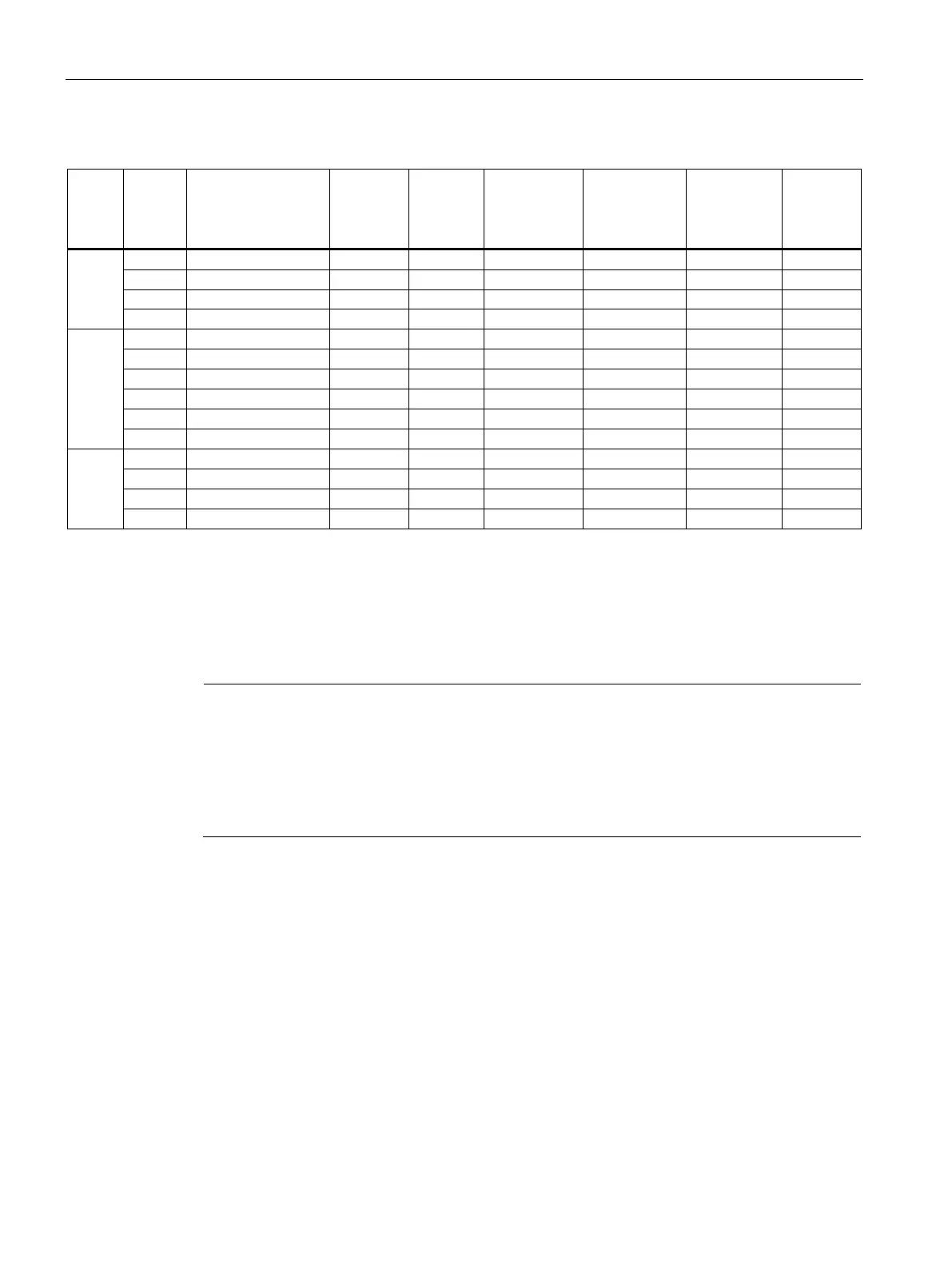

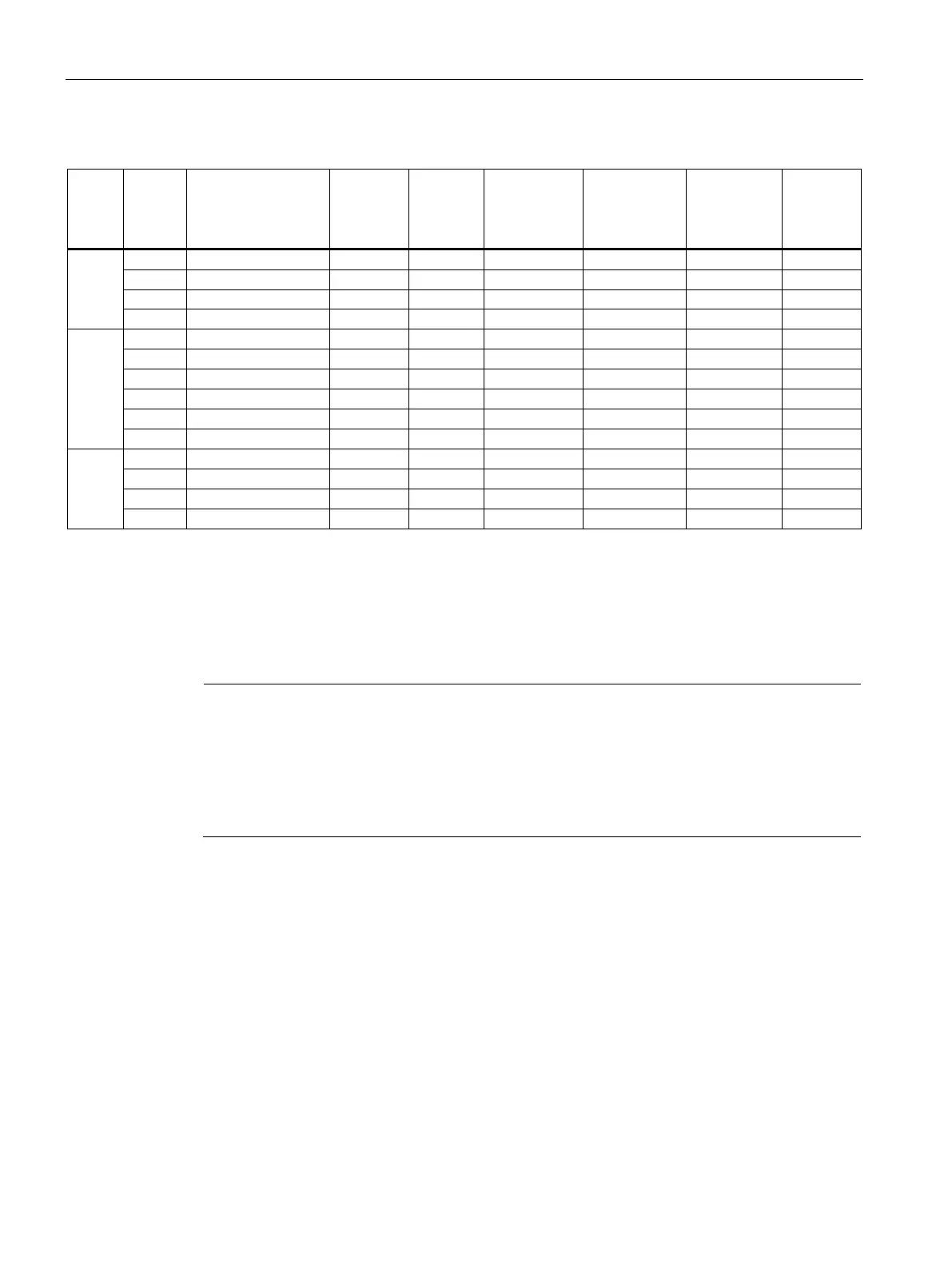

Table 8- 4 Cable cross-sections (Cu) and outer diameter of the connecting cables in the standard version

Cable entry

max. diam. /

width A/F

(mm)

Max. con-

ductor cross-

section

1)

(mm

2

)

150

N

N

N

200

N

N

N

N

N

Option M02: Terminal box GK 603 with removable front plate

Option P01: Cable entry plate 3 x M63 x 1.5 for terminal box 1XB7-700

Option P04: Cable entry plate 4 x M63 x 1.5 for terminal box 1XB7-712

1FW3206-3❑P supplied as standard with 1XB7-700. Terminal box GK 630 is possible on request.

5)

You must order the options separately.

-CONNECT 500 power cables are available up to a cross-section of 120 mm² and

-CONNECT 800PLUS up to 50 mm

2

.

The listed cables are UL and/or CSA approved.

be taken from the current catalog in Chapter "MOTION-CONNECT

8.3.3 Signal connection/motor protection

DRIVE-CLiQ is the preferred method for connecting the encoder systems to SINAMICS.

Motors with a DRIVE-CLiQ interface can be ordered for this purpose. Motors with a DRIVE-

CLiQ interface can be directly connected to the associated motor module via the available

MOTION-CONNECT DRIVE-CLiQ cables. The MOTION-CONNECT DRIVE-CLiQ cable is

connected to the motor in degree of protection IP67. The DRIVE-CLiQ interface supplies

power to the motor encoder via the integrated 24 V DC supply and transfers the motor

encoder and temperature signals and the electronic type plate data, e.g. a unique

identification number, rating data (voltage, current, torque) to the control unit. The MOTION-

CONNECT DRIVE-CLiQ cable is used universally for connecting the various encoder types.

These motors simplify commissioning and diagnostics, as the motor and encoder type are

identified automatically.

Loading...

Loading...