Configuration

5.2 Configuring workflow

1FW3 complete torque motors

92 Configuration Manual, 08/2020, A5E46027705B AA

5.2 Configuring workflow

Motion Control

Servo drives are optimized for motion control applications. They execute linear or rotary

movements within a defined movement cycle. All movements should be optimized in terms

of time.

As a result of these considerations, servo drives must meet the following requirements:

● High dynamic response, i.e. short rise times

● Capable of overload, i.e. a high reserve for accelerating

● Wide control range, i.e. high resolution for precise positioning

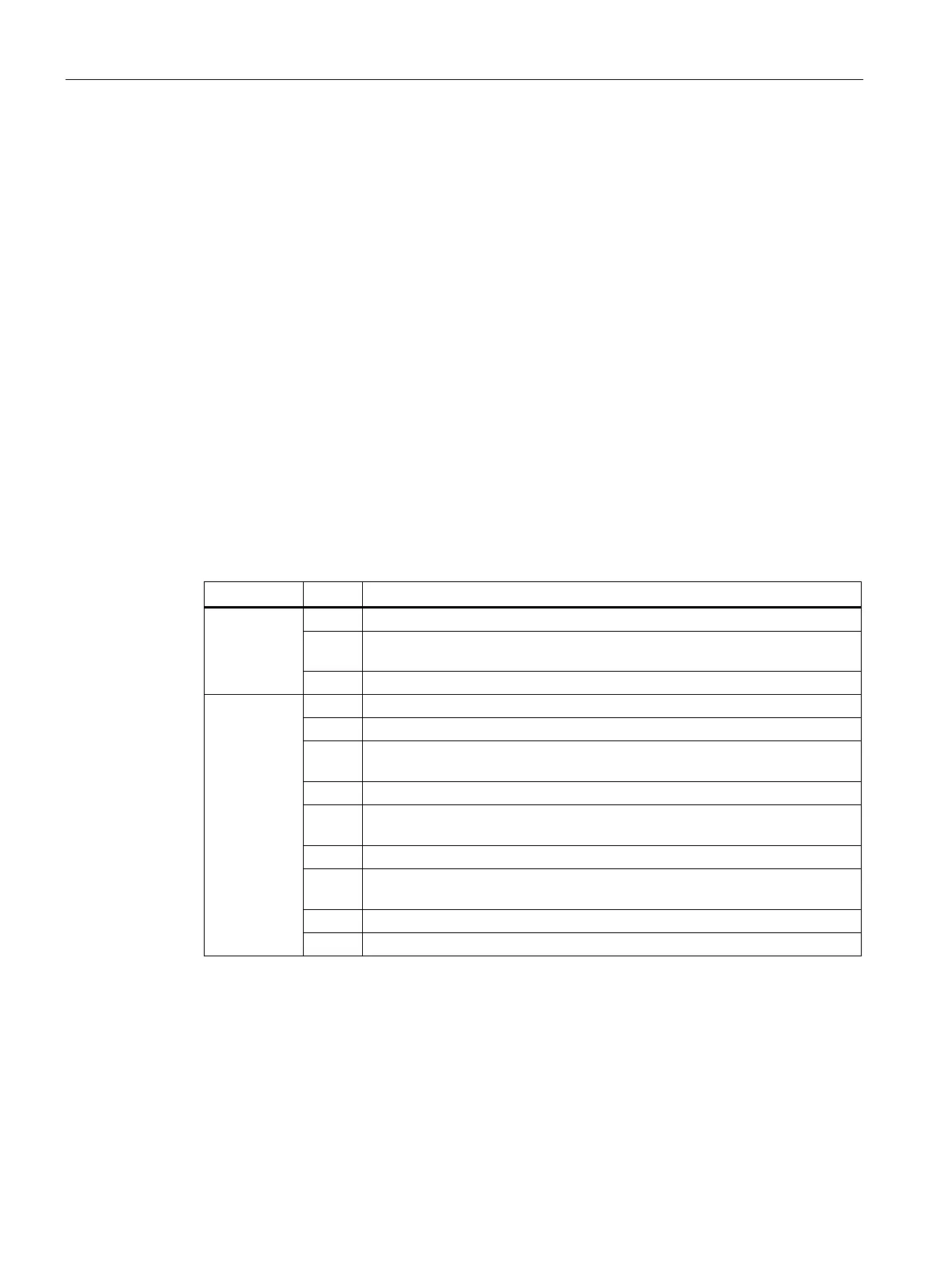

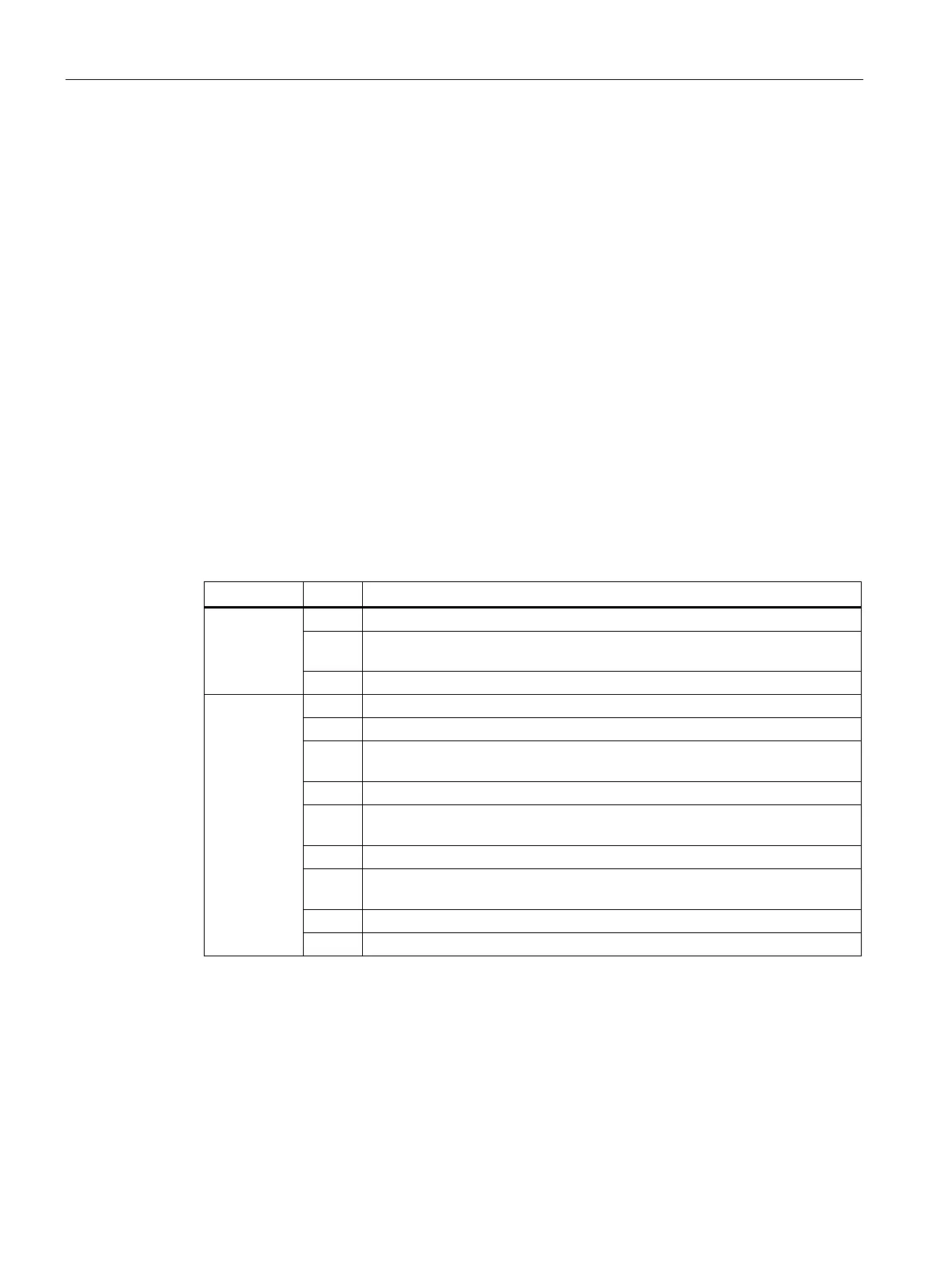

General procedure when engineering

The function description of the machine provides the basis when engineering the drive

application. The definition of the components is based on physical interdependencies and is

usually carried-out as follows:

Description of the engineering activity

See following

sections

Clarify the type of drive/infeed type

2. Define the supplementary conditions and integrate the drive/infeed into an

automation system

Define the load, calculate the max. load torque and select the motor

See

Catalog

4. Select a SINAMICS Motor Module

Repeat step 3 and step 4 for additional axes

6. Calculate the required DC link power and select an appropriate SINAMICS

Select the line-side options (main switch, fuses, line filters, etc.)

8. Select a Control Unit based on the specification of the required control per-

formance, and define the component cabling

Define and select the additional system components

10. Calculate the current demand of the 24 V DC supply for the components

and specify the power supplies (SITOP devices, control supply modules)

Select the components for the connection system

Configurate the components of the drive line-up

Loading...

Loading...