Mechanical properties

3.10 Bearing change intervals

1FW3 complete torque motors

Configuration Manual, 08/2020, A5E46027705B AA

69

3.10 Bearing change intervals

Bearing lifetime and regreasing interval

The bearings for the complete torque motors are greased for life and designed for operation

at a minimum ambient temperature of - 15 °C.

Note

Bearings without regreasing system

For bearings without regreasing system (SH 150 and SH 200), we recommend that the

bearings are replaced after approx. 20000 operating hours for an am

bient temperatures up

to a maximum of 40°C, or after 5 years (after delivery) at the latest.

fetime is reduced by 50 % when motors are mounted vertically. This is the

reason that we recommend that a regreasing system is used when motors are m

ounted

Regreasing system (option for 1FW315x and 1FW320x, standard for 1FW328x)

If the 1FW3 is equipped with regreasing system (bevel lubricating nipple) for the DE and

NDE bearings, then the bearing change interval increases according to the table "Bearings

with regreasing system". Comply with the regreasing intervals and ensure that the

temperature does not exceed a maximum of 40 °C.

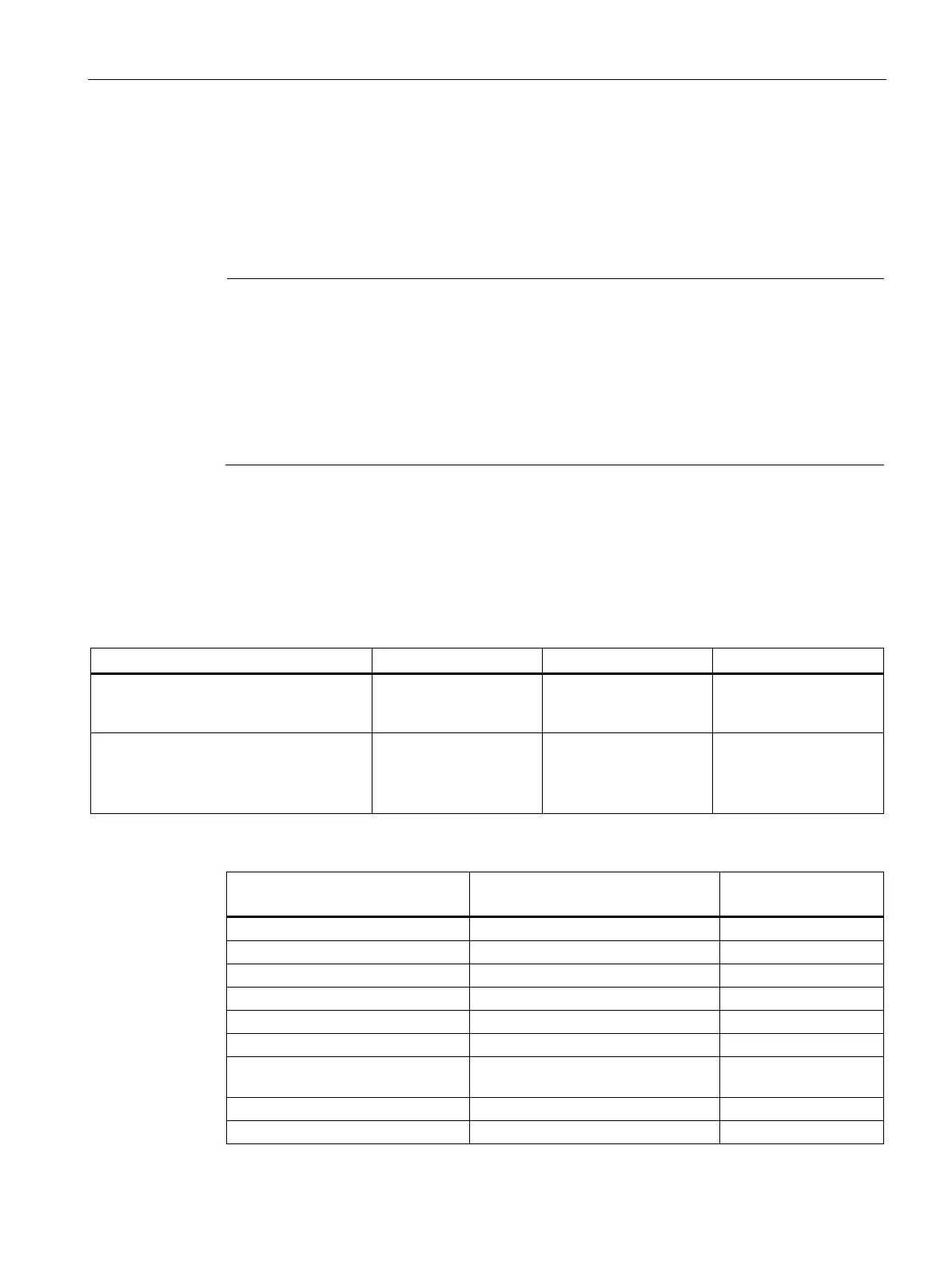

Table 3- 12 Bearing change interval and regreasing

Bearing change interval with permanent

grease lubrication, horizontal mounting

20,000 h at max. 40 °C

ambient temperature

20,000 h at max. 40 °C

ambient temperature

---

Regreasing Option +K40

See table "Bearings with

regreasing system"

Option +K40

See table "Bearings with

regreasing system"

Regreasing in the

standard

See table "Bearings with

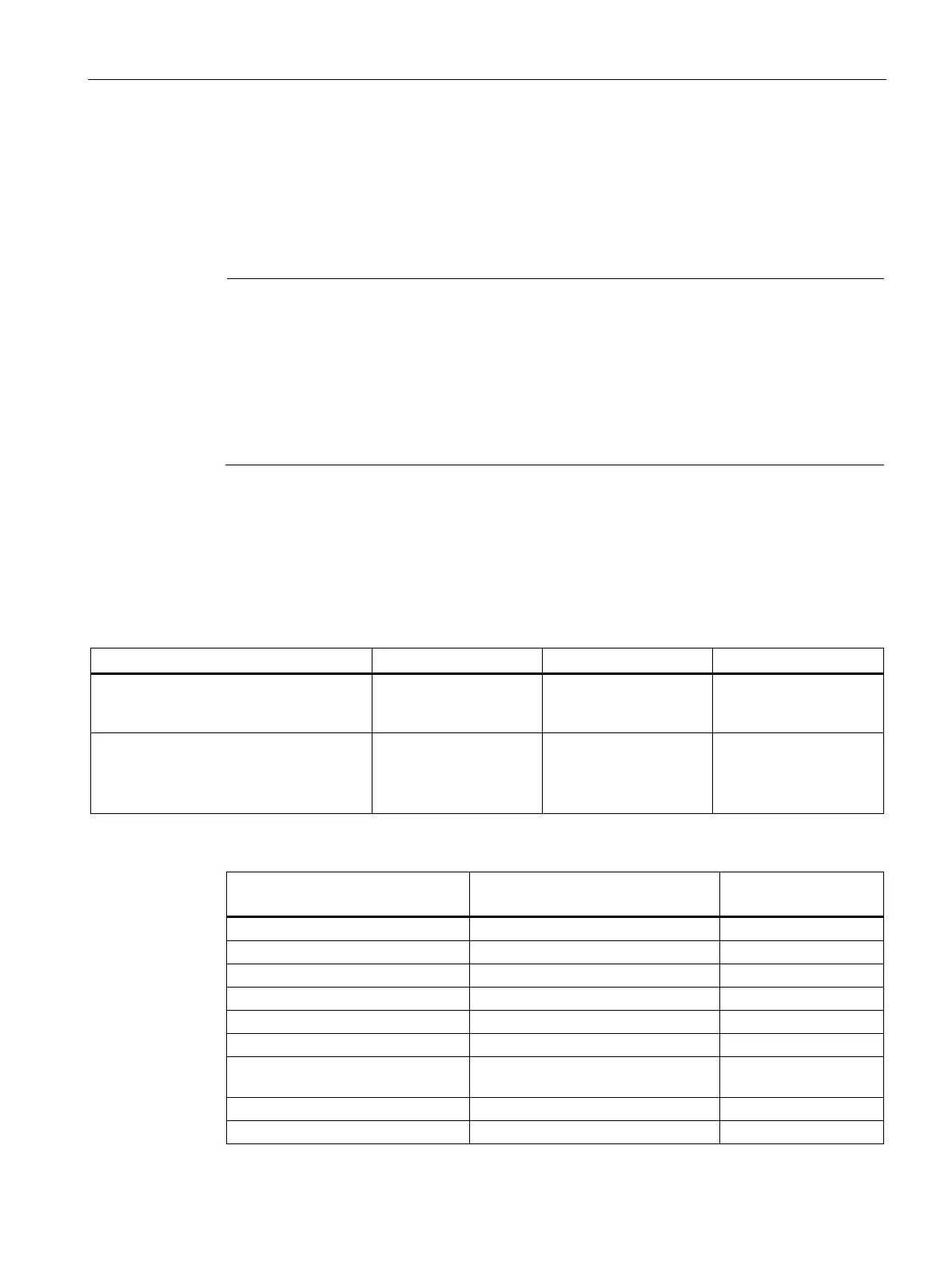

Table 3- 13 Bearings with regreasing system (optional for 1FW315❑ and 1FW320❑)

Bearing change interval with re-

greasing [h]

1FW328❑-2 n

N

= 150/250 hollow

40000 10000

1FW328❑-3 n

N

= 400 hollow shaft

N

Loading...

Loading...