Mechanical properties

3.1 Cooling

1FW3 complete torque motors

Configuration Manual, 08/2020, A5E46027705B AA

47

3.1.3 Cooling water

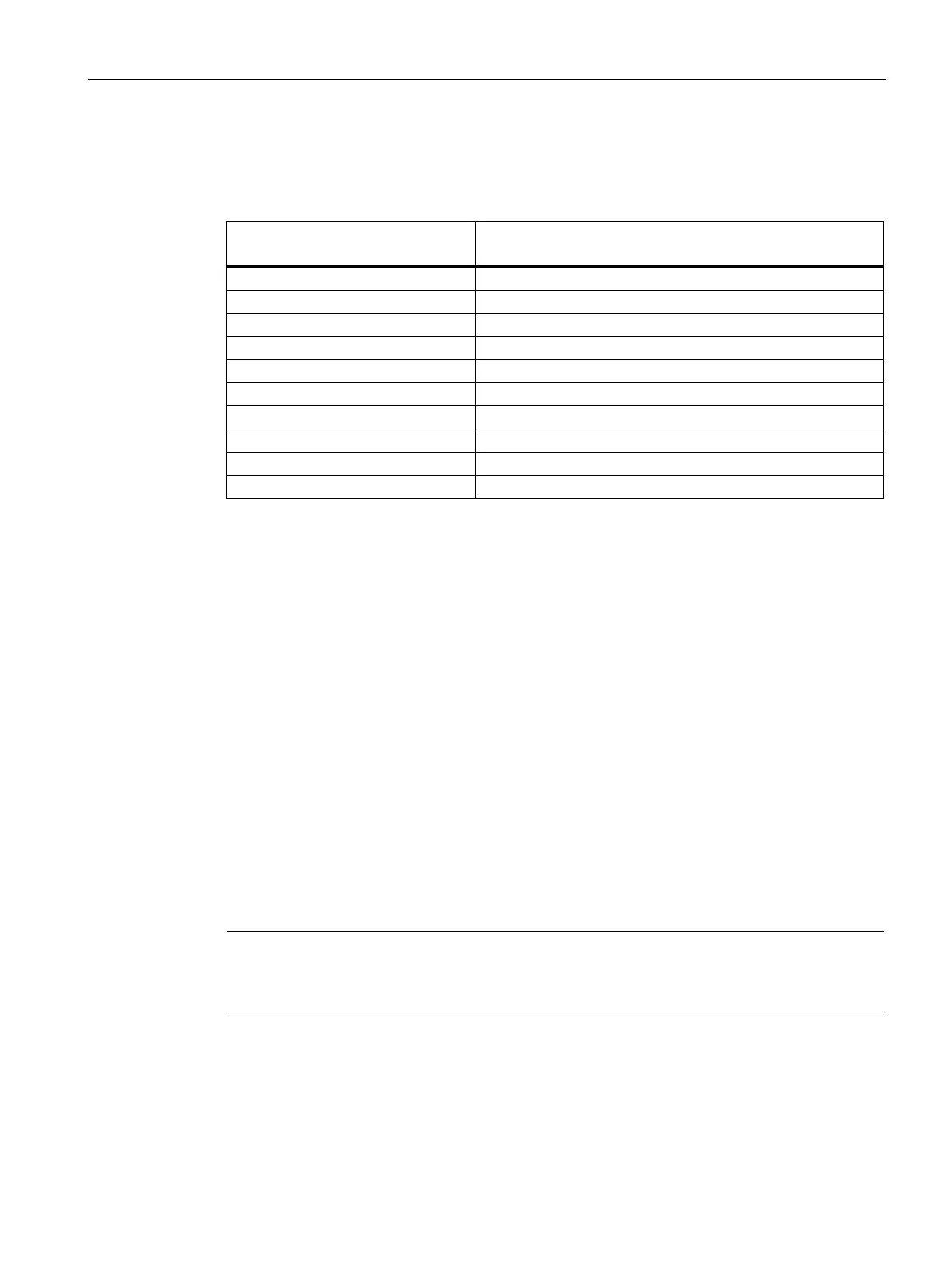

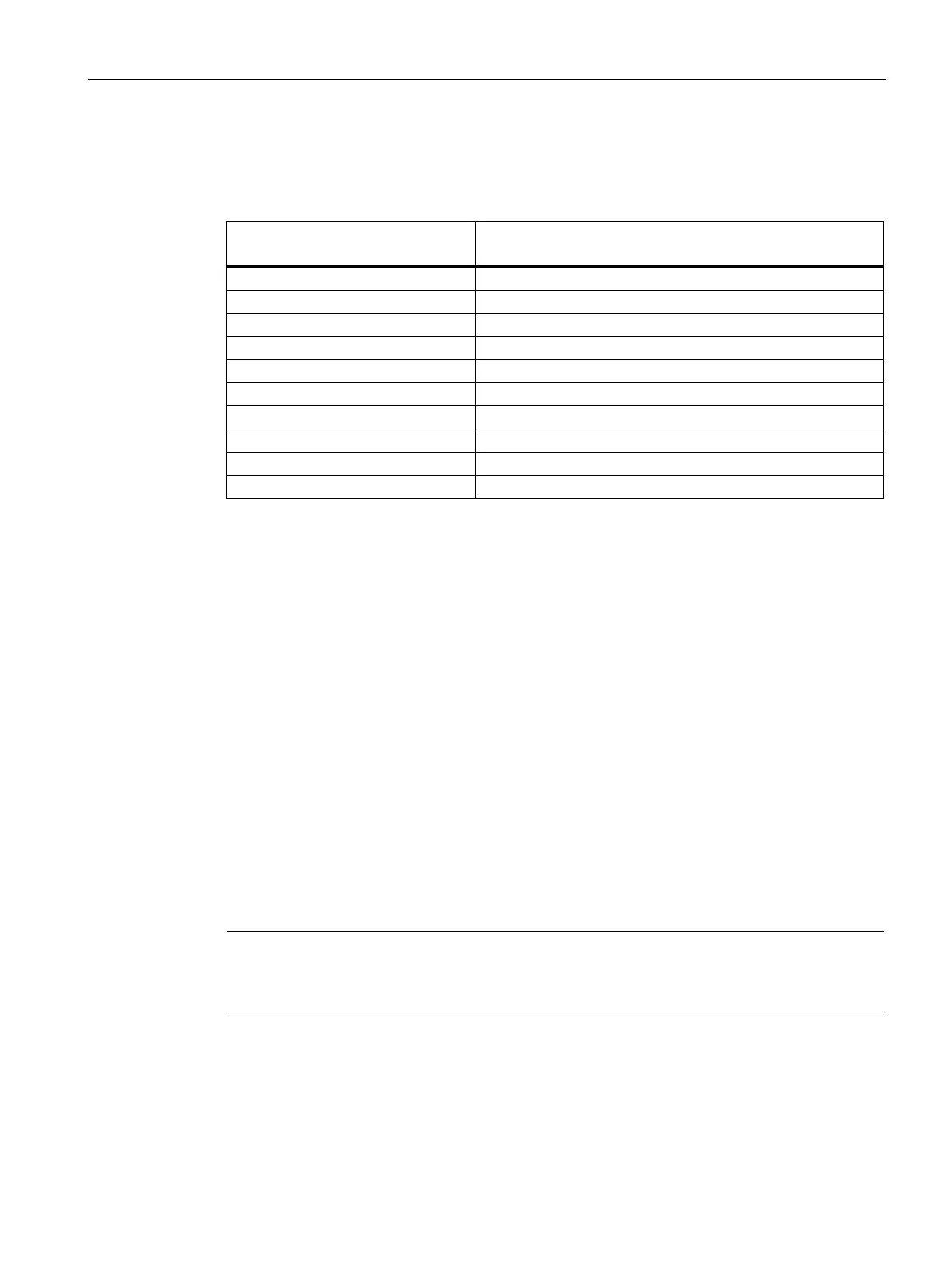

Table 3- 6 Water specification as coolant

Quality of the water used as coolant for motors with alumi-

num, stainless steel tubes + cast iron or steel jacket

< 40 ppm, can be achieved by adding deionized water.

pH value 6 ... 9 (with aluminum 6 ... 8)

Size of entrained particles

0.2 ... 0.25% inhibitor Nalco TRAC100 (previously 0GE056)

If necessary 20 ... 30% Antifrogen N (manufacturer Clariant)

Biocide

The risk of corrosion caused by microbes is virtually non-existent in chlorinated drinking

water systems.

Closed cooling circuits with soft water are susceptible to microbes.

The following types of microbes are encountered in practice:

● Slime-forming bacteria

● Corrosive bacteria

● Iron-depositing bacteria

The suitability of a biocide depends on the type of microbe.

● Analyze the cooling water for microbes at least once a year.

Necessary biocides can be obtained from the manufacturer, e.g. Nalco. Ask the

manufacturer for compatibility with an inhibitor used in your system.

● Dose the biocide as recommended by the manufacturer.

Antifrogen N already acts like a biocide at the minimum concentration of > 20%.

Note

Compatibility of coolant additives

Biocides and Antifro

gen N must not be mixed.

There are other manufacturers of chemical additives in the market. You can use equivalent

products from other manufacturers. Have the suitability of the third-party products

determined.

Loading...

Loading...