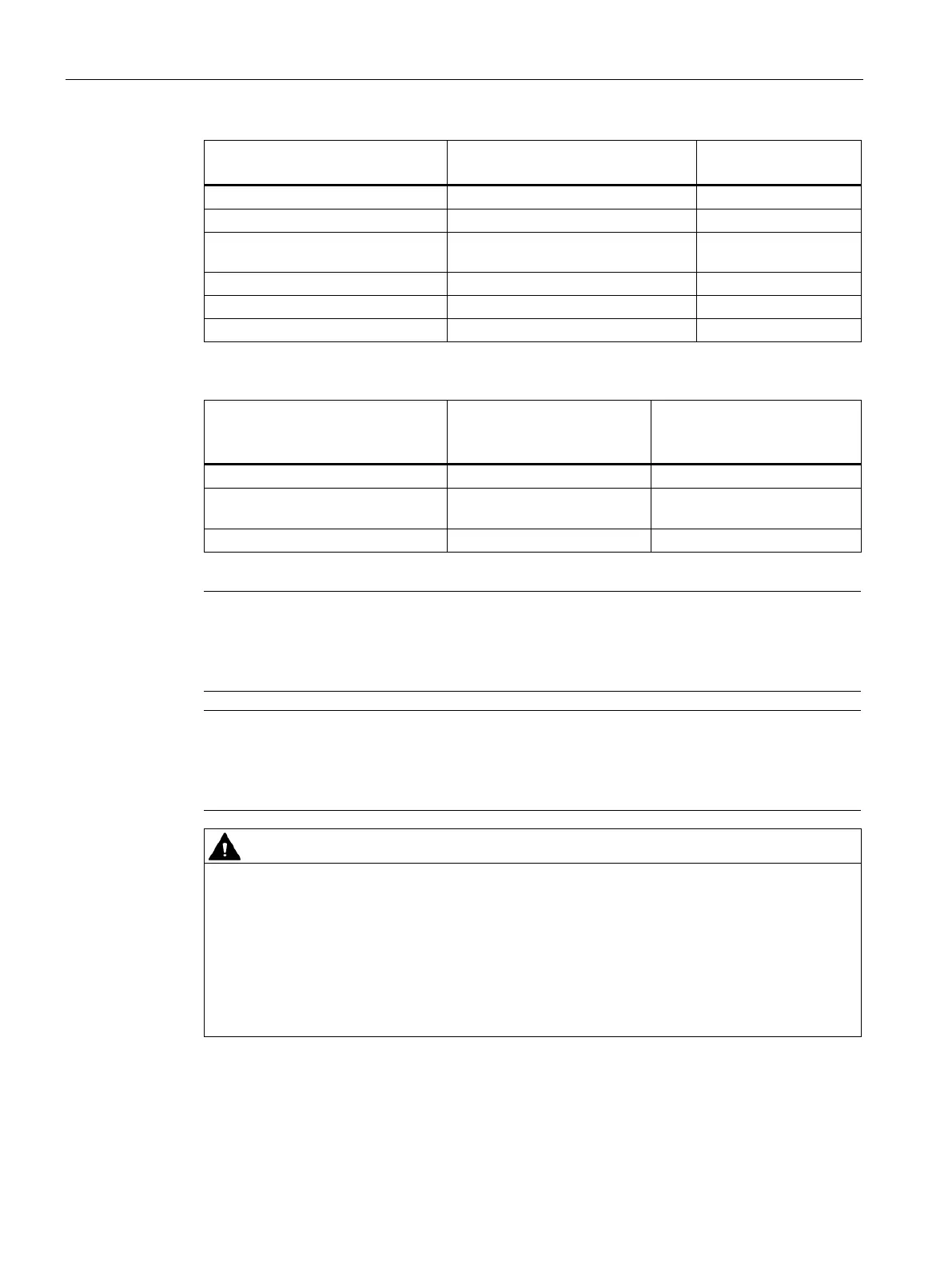

Mechanical properties

3.10 Bearing change intervals

1FW3 complete torque motors

70 Configuration Manual, 08/2020, A5E46027705B AA

Bearing change interval with re-

greasing [h]

1FW328❑-3 n

N

= 800 hollow shaft

1FW328❑-2/3 plug-on shaft

1FW328❑-2 n

N

= 150/250 solid

40000 10000

1FW328❑-3 n

N

= 400 solid shaft

N

1FW328❑-3 n

N

= 800 solid shaft

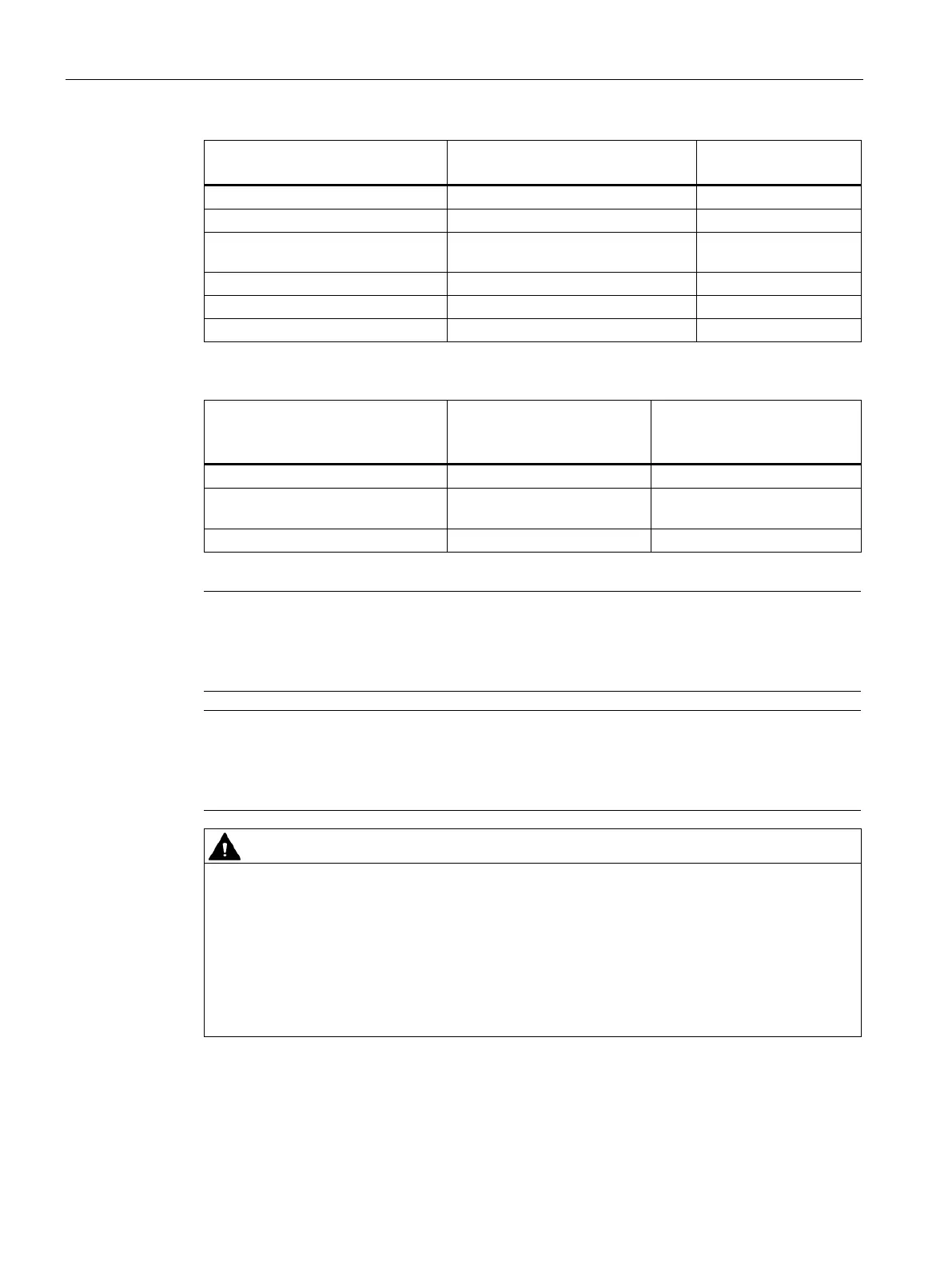

Table 3- 14 Bearing grease

Option +V07

"Special grease for low

speeds"

Bearing grease designation

Klüber Lubrication München

SKF AG

Note

Specified grease quantity

For motors with

the option +K40 "regreasing system", the required grease quantity is stated

on the bearing data labeling plate.

Note

Vertical mounting position

The regreasing interval is reduced to 50% and therefore the bearing replacement interval

whe

n motors are mounted vertically.

Danger to life as a result of parts of the body being drawn in and crushed

Operational motors can draw in body parts, crush them or cause other injuries.

• Only lubricate bearings if there is absolutely no risk to personnel.

• When working on an operational motor only wear clothes and accessories that cannot

be drawn in.

• Take the appropriate measures so that your hair cannot be pulled in by the motor,

• Only regrease the bearings at the slowest speed that can be adjusted

Loading...

Loading...