Mechanical properties

3.10 Bearing change intervals

1FW3 complete torque motors

Configuration Manual, 08/2020, A5E46027705B AA

71

Regreasing

Procedure

1. Set the lowest possible speed.

2. Grease the bearings at the lowest possible speed with the specified amount of grease.

You have greased the bearings.

❒

The recommended re-lubricating intervals relate to normal loads:

● Operation at speeds in accordance with the rating plate data

● Low-vibration operation, see Chapter "Vibration resistance (Page 146)"

● Use of the specified roller bearing greases

Option +V07 "Special grease for low speeds"

For option +V07 "Special grease for low speeds", for shaft heights 150 and 200, you require

option K40 "Relubrication device". Motors of shaft height 280 are equipped with a

relubrication device as standard. You do not require option K40 for these motors.

For motors with an average speed smaller than 100 rpm, you need the option +V07.

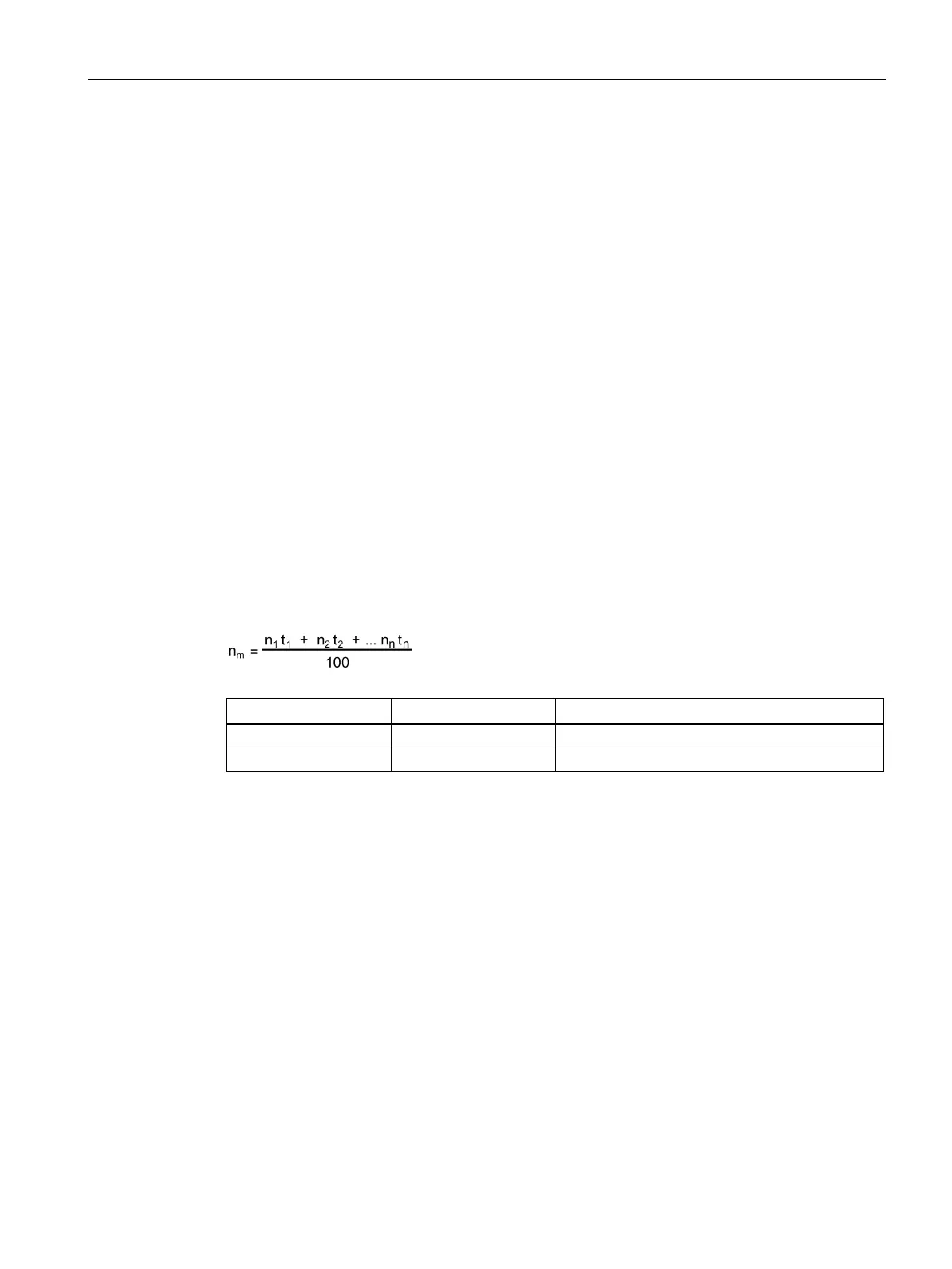

You can calculate the average operating speed n

m

by the following formula:

Time percentage of the bearing load

1

n

You therefore calculate an average speed from the different speeds according to their time

percentages.

Special versions

Unfavorable factors (e.g. effects of mounting/installation, speeds, special modes of operation

or high mechanical loads) may require special measures.

Contact your local Siemens office, specifying the prevailing general conditions.

Loading...

Loading...