8

Tool Offsets 04.00

8.3 Online tool offset PUTFTOCF

PUTFTOC

FTOCON

FTOCOF

8

840D

NCU 572

NCU 573

840Di

Siemens AG 2000. All rights reserved

8-270

SINUMERIK 840D/840Di/810D/FM-NC Programming Guide Advanced (PGA)

−

04.00 Edition

Function

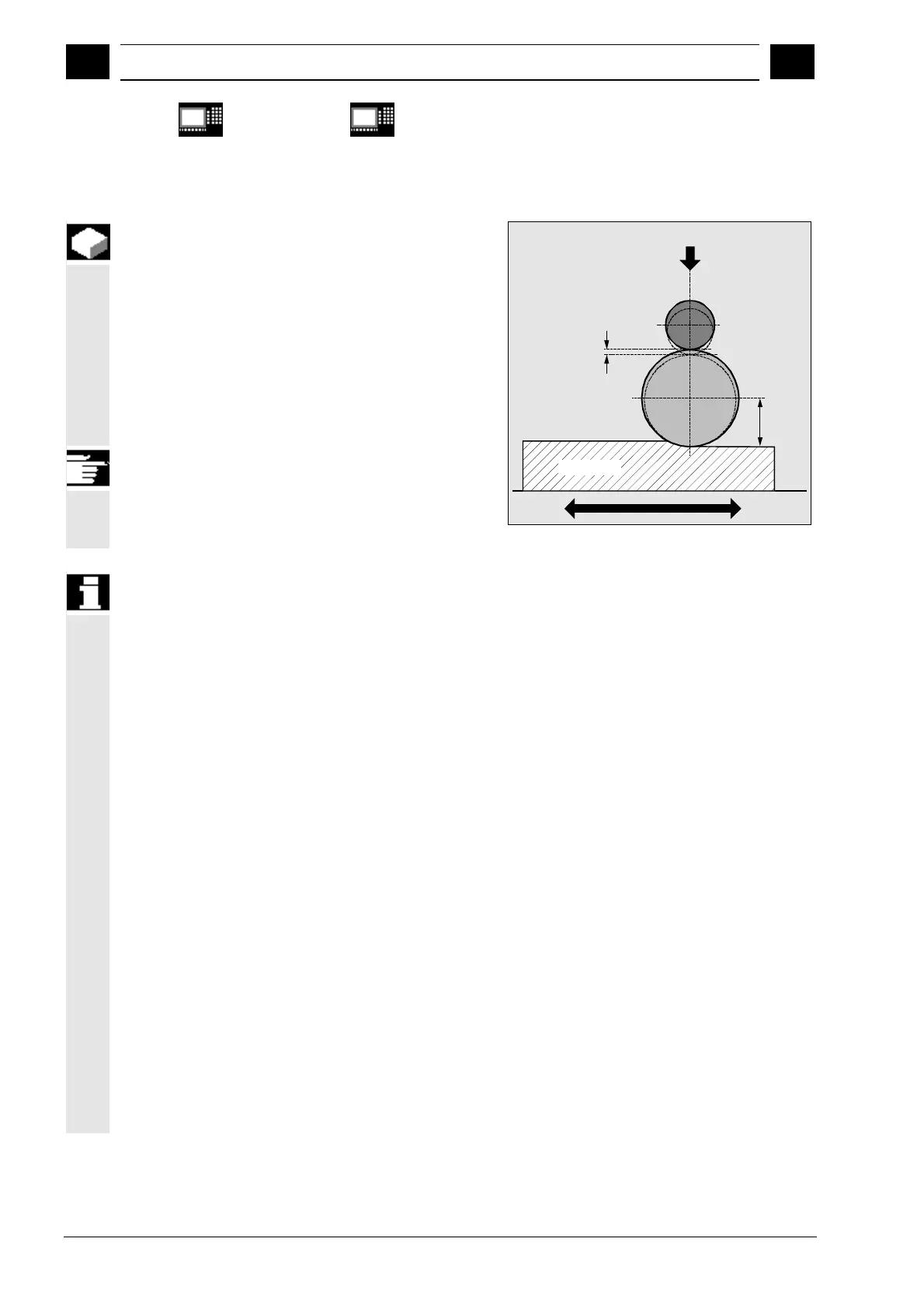

The function makes immediate allowance for tool

offsets resulting from machining by means of online

tool length compensation (e.g. CD dressing: the

grinding wheel is dressed parallel to machining). The

tool length compensation can be changed from the

machining channel or a parallel channel (dresser

channel).

Online tool offset can be applied only to grinding

tools.

Dressing roll

Dressing

amount

Workpiece

Grinding

wheel

Length 1

General information about online TO

Depending on the timing of the dressing process, the

following functions are used to write the online tool

offsets:

•

Continuous write, non-modal: PUTFTOCF

•

Continuous write, modally: ID=1 DO FTOC

(see Chapter Synchronized actions)

•

Discrete write: PUTFTOC

In the case of a continuous write (for each

interpolation pulse) following activation of the

evaluation function each change is calculated

additively in the wear memory in order to prevent

setpoint jumps.

In both cases:

The online tool offset can act on each spindle and

lengths 1, 2

or

3 of the wear parameters.

The assignment of the lengths to the geometry axes

is made with reference to the current plane.

The assignment of the spindle to the tool is made

with reference to the tool data with GWPSON or

TMON as long as it is not the active grinding wheel

(see Programming Guide "Fundamentals").

Loading...

Loading...