1

Flexible NC Programming 02.98

1.14 Interru

t routine

1

840D

NCU 571

840D

NCU 572

NCU 573

810D

840Di

Siemens AG 2000. All rights reserved

1-68

SINUMERIK 840D/840Di/810D/FM-NC Programming Guide Advanced (PGA)

−

04.00 Edition

1.14 Interrupt routine

Programming

SETINT(3) PRIO=1 NAME

SETINT(3) PRIO=1 LIFTFAST

SETINT(3) PRIO=1 NAME LIFTFAST

G… X… Y… ALF=…

DISABLE(3)

ENABLE(3)

CLRINT(3)

Explanation of the commands

SETINT(n)

Start interrupt routine if input n is enabled, n (1...8) stands for the

number of the input

PRIO=1

Define priority 1 to 128 (1 has top priority)

LIFTFAST

Fast lift from contour

NAME

Name of the subprogram to be executed

ALF=…

Programmable traverse direction (in motion block)

DISABLE(n)

Deactivate interrupt routine number n

ENABLE(n)

Reactivate interrupt routine number n

CLRINT(n)

Clear interrupt assignments of interrupt routine number n

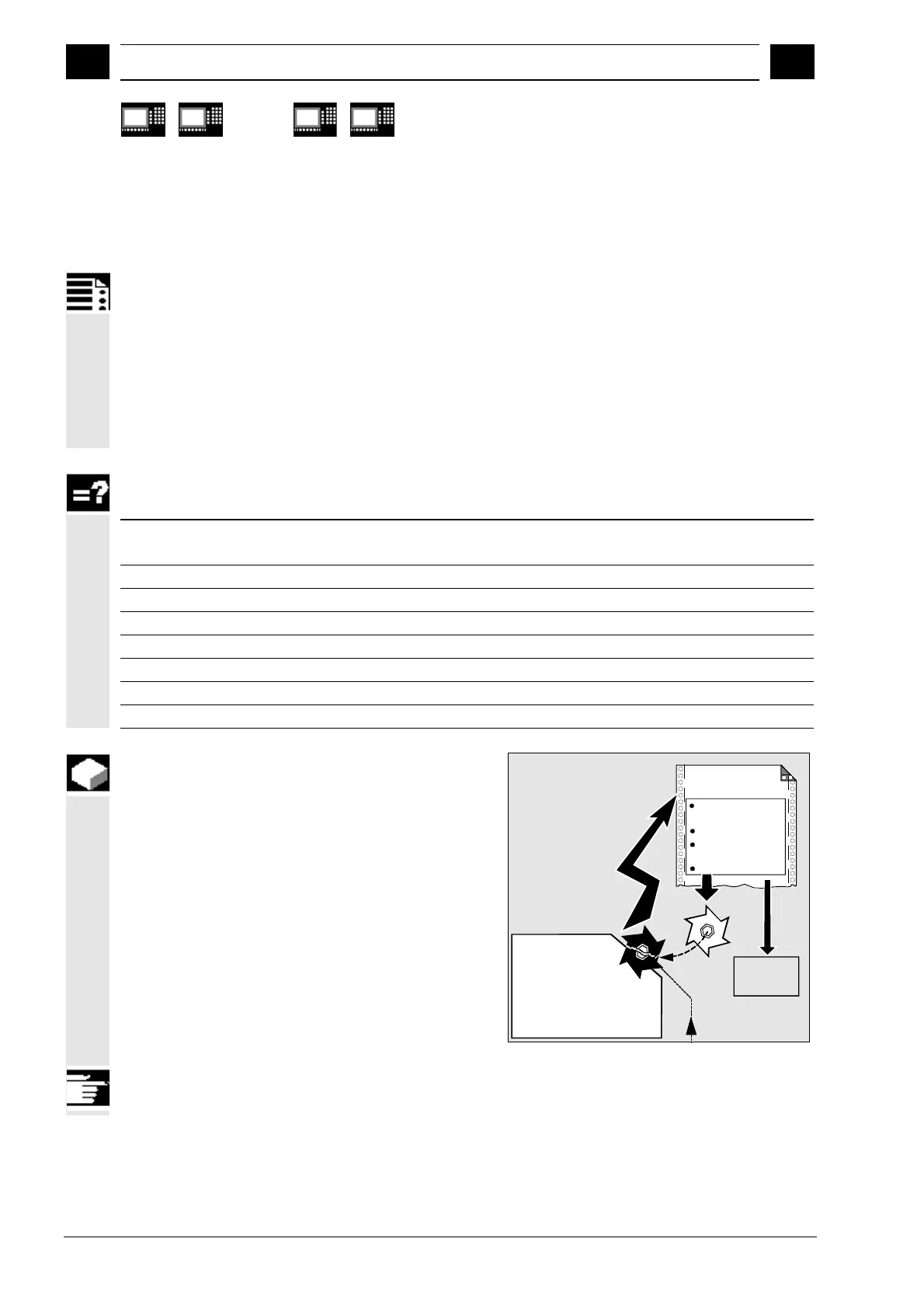

Function

Example: The tool breaks during machining. This

triggers a signal that stops the current machining

process and simultaneously starts a subprogram this

subprogram – is called an interrupt routine. The

interrupt routine contains all the instructions which

are to be executed in this case.

When the interrupt routine has finished being

executed and the machine is ready to continue

operation, the control jumps back to the main

program and continues machining at the point of

interruption – depending on the REPOS command.

Main

program

Interrupt routine

Withdraw from

contour

Tool change

New offset

values

Reposition

For further information on REPOS, see Chapter 9,

Path Traversing Behavior, Repositioning.

Loading...

Loading...